Platinum metals are elements of the 5th and 6th transition periods of the periodic table. They are characterized by the filling of 4d and 5d electron orbitals with the presence of one or two s electrons in higher (5s and 6s electron) orbitals.

Some compounds of ruthenium and osmium are in many ways reminiscent of the corresponding compounds of iron, an element of the same group of the 4th period. Rhodium is similar in behavior in some metallurgical processes to cobalt, palladium and platinum are similar to nickel.

The similarity of the configurations of the outer electron shells in the atoms of platinum metals and the proximity of effective atomic radii determine the similarity of the chemical properties of the elements. The greatest analogies are manifested in the elements that stand next to each other in the periodic table: ruthenium and osmium, rhodium and iridium, palladium and platinum.

Elements that are adjacent horizontally exhibit noticeable differences in properties. Due to the similarity of the structures of the last electronic level, there is a similarity in the properties of some similar compounds of elements located diagonally: ruthenium and iridium, rhodium and platinum.

Being elements of transition periods, platinum metals are characterized by different states of oxidation. They do not have a tendency to gain electrons; they only have a metallic character. The maximum possible, as well as characteristic, oxidation states increase from top to bottom vertically (the distance of the outer electron shells from the nucleus increases) and decrease from left to right horizontally (d-orbitals are gradually filled with electrons).

Osmium and ruthenium, which have eight outer electrons, are capable of exhibiting maximum oxidation states VII and VIII (especially with oxygen and oxyhalides). Oxidation state VI, characteristic of ruthenium, osmium and only sometimes platinum, iridium and rhodium, is realized mainly in oxygen compounds.

For ruthenium, osmium, platinum and iridium, the most characteristic oxidation state is IV, for rhodium - III, although oxidation state III is quite common in ruthenium and iridium compounds. Lower oxidation states (II, I) in rhodium, ruthenium, iridium, and osmium are less common. They are mainly characterized by their compounds with organic lithandes. Oxidation states I and 0 for all platinum metals occur very rarely, mainly in carbonyl compounds.

Due to their high charges, small ionic radii, and the presence of unfilled d-orbitals, platinum metals are typical complexing agents. Thus, in solutions, all their compounds, including simple ones (halides, sulfates, nitrates), are converted into complex ones, since ions of the compounds present in the solution, as well as water, participate in complex formation. Therefore, the hydrometallurgy of platinum metals is based on the use of their complex compounds.

Platinum group metals: overview, list, properties and applications

The platinum group metals are six noble, precious chemical elements that are located side by side on the periodic table. All of them are transition metals of 8–10 groups of 5–6 periods.

Platinum group metals: list

The group consists of the following six chemical elements, arranged in order of increasing atomic weight:

- Ru – ruthenium.

- Rh – rhodium.

- Pd – palladium.

- Os – osmium.

- Ir – iridium.

- Pt – platinum.

The platinum group metals are silvery-white in color, with the exception of osmium, which is bluish-white. Their chemical behavior is paradoxical in that they are highly resistant to most reagents, but are used as catalysts that easily accelerate or control the rate of oxidation, reduction, and hydrogenation reactions.

Ruthenium and osmium crystallize into a hexagonal close-packed system, while others have a face-centered cubic structure. This is reflected in the greater hardness of ruthenium and osmium.

History of discovery

Although platinum-bearing gold artifacts date back to 700 BC. e., the presence of this metal is more likely an accident than a pattern. Jesuits in the 16th century mentioned gray dense pebbles associated with alluvial gold deposits.

These stones could not be melted, but they formed an alloy with gold, and the ingots became brittle and could no longer be cleaned.

The pebbles came to be called platina del Pinto - granules of silvery material from the Pinto River, which flows into the San Juan River in Colombia.

Malleable platinum, which can only be obtained after complete purification of the metal, was isolated by the French physicist Chabanot in 1789. It was used to make a cup presented to Pope Pius VI. The discovery of palladium in 1802 was reported by the English chemist William Wollaston, who named the chemical. element of the platinum group of metals in honor of the asteroid.

Wollaston subsequently claimed to have discovered another substance present in platinum ore. He named it rhodium because of the pink color of the metal salts.

The discoveries of iridium (named after the rainbow goddess Iris because of the variegated color of its salts) and osmium (from the Greek word for "smell" because of the chlorine odor of its volatile oxide) were made by the English chemist Smithson Tennant in 1803.

French scientists Hippolyte-Victor Collet-Descoti, Antoine-François Fourcroy, and Nicolas-Louis Vauquelin isolated the two metals simultaneously. Ruthenium, the last element isolated and identified, received its name from the Latin name for Russia from the Russian chemist Karl Karlovich Klaus in 1844.

In contrast to substances such as gold, silver, which are easily isolated in a relatively pure state by simple fire refining, platinum group metals require complex water-chemical processing. These methods were not available until the late 19th century, so identification and isolation of the platinum group lagged behind silver and gold by thousands of years.

Additionally, the high melting point of these metals limited their use until researchers in Britain, France, Germany, and Russia developed methods to convert platinum into a workable form. How platinum group precious metals have been used in jewelry since 1900.

Although such applications remain relevant today, industrial applications have far surpassed them.

Palladium became a highly sought after contact material in telephone relays and other wired communication systems, providing long life and high reliability, and platinum, because of its resistance to spark erosion, was used in combat aircraft spark plugs during World War II.

After the war, the expansion of molecular conversion techniques in petroleum refining created a huge demand for the catalytic properties possessed by platinum group metals. By the 1970s, consumption increased even further when automobile emissions standards in the United States and other countries led to the use of these chemicals in catalytic conversion of exhaust gases.

Ore

With the exception of small placer deposits of platinum, palladium and osmic iridium (an alloy of iridium and osmium), there is practically no ore in which the main component is the chemical element - a platinum group metal. The minerals are typically found in sulfide ores, particularly pentlandite (Ni, Fe)9S8. The most common are laurite RuS2, irarsite, (Ir,Ru,Rh,Pt)AsS, osmiridium (Ir,Os), cooperite, (PtS) and braggite (Pt,Pd)S.

The world's largest deposit of platinum group metals is the Bushveld complex in South Africa. Large reserves of raw materials are concentrated in the Sudbury deposits in Canada and the Norilsk-Talnakh deposits in Siberia.

In the United States, the largest deposits of platinum group minerals are located in Stillwater, Montana, but there they are much smaller than in South Africa and Russia.

The world's largest platinum producers are South Africa, Russia, Zimbabwe and Canada.

Mining and enrichment

The main South African and Canadian deposits are exploited by mining.

Virtually all platinum group metals are recovered from copper or nickel sulfide minerals using flotation separation.

Smelting the concentrate produces a mixture that is washed out of copper and nickel sulfides in an autoclave. The solid leach residue contains 15 to 20% platinum group metals.

Gravity separation is sometimes used prior to flotation. The result is a concentrate containing up to 50% platinum metals, eliminating the need for smelting.

Mechanical properties

Platinum group metals differ significantly in their mechanical properties. Platinum and palladium are quite soft and very malleable.

These metals and their alloys can be worked in both hot and cold conditions. Rhodium is first worked hot and can later be worked cold with fairly frequent annealing.

Iridium and ruthenium must be heated; they cannot be cold processed.

Osmium is the hardest of the group and has the highest melting point, but its tendency to oxidize has its limitations. Iridium is the most corrosion-resistant of the platinum metals, and rhodium is valued for maintaining its properties at high temperatures.

Structural Applications

Because clean annealed platinum is so soft, it is susceptible to scratches and deterioration. To increase hardness, it is alloyed with many other elements. Platinum jewelry is very popular in Japan, where it is called "hakkin" and "white gold."

Jewelry alloys contain 90% Pt and 10% Pd, which is easy to process and solder. The addition of ruthenium increases the hardness of the alloy while maintaining oxidation resistance.

Alloys of platinum, palladium and copper are used in forged products because they are harder than platinum-palladium and less expensive.

Crucibles used to produce single crystals in the semiconductor industry require corrosion resistance and stability at high temperatures. Platinum, platinum-rhodium and iridium are best suited for this application.

Platinum-rhodium alloys are used in the production of thermocouples, which are designed to measure elevated temperatures up to 1800 °C. Palladium is used both in pure and mixed form in electrical devices (50% of consumption) and in dental alloys (30%).

Rhodium, ruthenium and osmium are rarely used in their pure form - they serve as an alloying additive for other platinum group metals.

Catalysts

About 42% of all platinum produced in the West is used as a catalyst. Of these, 90% are used in automotive exhaust systems, where refractory pellets or honeycomb structures coated with platinum (as well as palladium and rhodium) help convert unburned hydrocarbons, carbon monoxide and nitrogen oxides into water, carbon dioxide and nitrogen.

An alloy of platinum and 10% rhodium in the form of a red-hot metal mesh serves as a catalyst in the reaction between ammonia and air to produce nitrogen oxides and nitric acid.

When fed with a mixture of ammonia, methane can produce hydrocyanic acid.

In petroleum refining, platinum on the surface of alumina beads in a reactor acts as a catalyst to convert long-chain petroleum molecules into branched isoparaffins, which are desirable in high-octane gasoline blends.

Electroplating

All platinum group metals can be plated. Because of the hardness and shine of the resulting coating, rhodium is most often used. Although its cost is higher than platinum, its lower density allows it to use less material at a comparable thickness.

Palladium is a platinum group metal that is the easiest to use for coating. Thanks to this, the strength of the material increases significantly. Ruthenium has found use in tools designed for low-pressure friction machining.

Chemical compounds

Organic platinum group metal complexes, such as alkylplatinum complexes, are used as catalysts in the polymerization of olefins, the production of polypropylene and polyethylene, and the oxidation of ethylene to acetaldehyde.

Platinum salts are increasingly used in cancer chemotherapy. For example, they are part of drugs such as Carboplatin and Cisplatin. Ruthenium oxide coated electrodes are used in the production of chlorine and sodium chlorate. Rhodium sulfate and phosphate are used in rhodium plating baths.

Platinum group metals

PROPERTIES AND APPLICATIONS OF PLATINUM METALS

Platinum (Pt) was discovered in 1783. The name of the element comes from the Spanish word “plata” - silver, silver for its resemblance to silver.

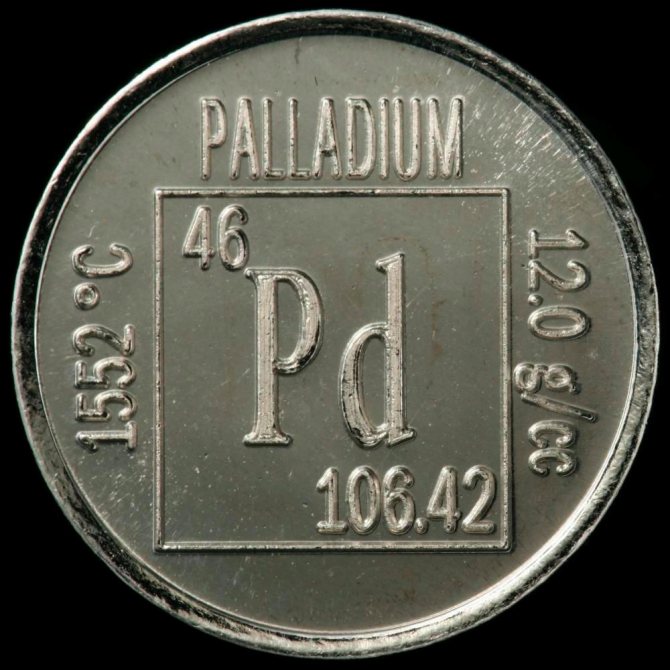

Palladium (Pd) was discovered in 1803 and named after the minor planet Pallas, discovered a year before the discovery of the element.

Rhodium (Rh) is a silvery-blue metal that resembles aluminum. The element was discovered in 1803. Its name comes from the Greek word “rhodos” - pink (the color for the pink color of its salts).

Iridium (Ir) was discovered in 1803. The name of the element comes from the Greek word “iridis” - rainbow for the bright and variegated colors of its salts.

Osmium (Os) was discovered in 1803. The name of the element comes from the Greek word “osme” - smelling for the pungent odor of osmium anhydride.

Ruthenium (Ru) is a silvery-white metal similar to platinum. The element was discovered in 1884 by the Russian chemist Clauss and named by him in honor of Russia, whose Latin name is Ruthenia.

Platinum tetrachloride, when dissolved in hydrochloric acid, forms hydroplatinic acid. Salts of this acid are chloroplatinates. Ammonium chloroplatinate (NH4)2[PtCl6] is slightly soluble in aqueous solutions and very slightly soluble in ammonium chloride solutions, which is of great importance in the refining of platinum metals. During dissociation as a result of thermal decomposition, ammonium chloride and chlorine are removed from the chloroplatinate in the form of gases, and the platinum remains in the form of a metal sponge.

Palladium, when dissolved in aqua regia, forms palladium chloride, which with hydrochloric acid gives palladium chloride acid H2PtCl6. The salt is chlorpalladosamine [Pd(NH3)2Cl2], which

TABLE. PHYSICAL PROPERTIES OF PLATINUM GROUP METALS

| Indicators | Pt | Ir | Os | Pd | Rh | Ru |

| Atomic mass | 195,09 | 192,2 | 190,2 | 106,4 | 102,91 | 101,1 |

| Density, kg/m3 10-3 | 21,45 | 22,41 | 22,48 | 12,16 | 12,41 | 12,2 |

| Temperature, °C: melting | 1769 | 2454 | 2700 | 1552 | 1966 | 2450 |

| Temperature, °C: boiling | 4530 | 5300 | 5500 | 3980 | 4500 | 2900 |

| Heat of fusion, cal/g | 27,8 | 28 | 35 | 37,8 | 52 | 46 |

| Specific heat capacity at 20°С, Cal/(g*deg) | 0,0317 | 0,0309 | 0,031 | 0,0586 | 0,0604 | 0,057 |

| Thermal conductivity, cal/ (cm sec deg) | 0,165 | 0,141 | — | 0,161 | 0,213 | — |

| Electrical resistivity at 25°C, μm/cm | 10,3 | 5,40 | 9,66 | 9,96 | 4,9 | 7,427 |

Platinum and palladium have good ductility at room temperature and are easily processed by pressure; their ductility is maintained at high degrees of compression. Iridium and rhodium are not ductile at room temperature and can be rolled and drawn into wire only at 1200-1400°C. Ruthenium and osmium are non-plastic even at 1500°C.

Platinum, like gold and silver, does not oxidize in air even when melted; Osmium and ruthenium are easily oxidized when heated in air. Iridium, palladium and rhodium also oxidize when heated in air, but to a lesser extent than osmium and ruthenium.

Iridium, ruthenium and rhodium do not dissolve in acids and in boiling aqua regia. Platinum is stable in acids, but dissolves in aqua regia. Palladium corrodes when exposed to hot nitric, hydrochloric and sulfuric acids. When heated, platinum group metals form brittle alloys with carbon.

Platinum is exposed to molten caustic alkalis and phosphorus. With sulfur, platinum forms sulfur and disulfur platinum - PtS and PtS2. With chlorine, platinum forms platinum tetrachloride PtCl4, stable up to 370°C. At higher temperatures it transforms into PtCl3, and heating to 435°C leads to the formation of platinum chloride PtCl2. At temperatures >582°C, divalent platinum decomposes with the release of metallic platinum PtCl2-*»Pt+Cl2.

obtained after sequential processing of palladium chloride acid and the resulting compounds, has low solubility and is therefore used to isolate palladium from solutions. During thermal decomposition, chloropalladose (M1in) dissociates, while ammonium chloride and hydrogen chloride are removed into the gas phase, and palladium remains in the form of a metal sponge.

Iridium at red-hot temperatures interacts with chlorine, resulting in chlorine and iridium chloride - 1rC14 and 1rC13. These compounds correspond to hydrochloric iridium acid H21gC16 and hydrochloric iridic acid H31gC1b. When an excess of ammonium chloride is added to a solution of H21gCl6, ammonium chloroiridate (NH4)2IrCl6 precipitates, which has insignificant solubility in solutions of ammonium chloride. This is used in the separation of platinum metals. Ammonium chloroiridate, when treated with hydrogen sulfide, oxalic acid and other reducing agents, turns into chloroiridite, which makes it possible to separate iridium from platinum, which does not form this type of compound.

Osmium, when fused with a mixture of alkali and sodium or barium peroxide, forms an alloy that dissolves in water. When this solution is treated with alcohol, sodium osminate Na2[OsC4] is formed.

When a solution of osmium and sodium is reduced with hyposulfite and treated with ammonium chloride, osmyltetramychloride [0s02(NH3)4]Cl2 is obtained, which is the starting compound for obtaining osmium powder.

In a finely ground state, osmium, when calcined in an air atmosphere, forms osmium tetroxide 0s04, which evaporates at 120°C and has a specific odor. With hydrogen it is reduced to dioxide GeO2.

Ruthenium with oxygen forms volatile tetroxide Ru04, which has a pungent odor and evaporates at 65°C. Ruthenium tetroxide is a strong oxidizing agent and, when in contact with concentrated ammonia or alcohol, is reduced with a strong explosion. When Ru04 is dissolved in hydrochloric acid and exposed to a solution of potassium chloride, a readily soluble salt of ruthenium chloride K2[RuC15OH] is obtained. Slightly soluble hexachlororutenates (NH4)r [RuCls], K2[RuC16] precipitate from solutions of this salt under the action of ammonia chloride or potassium.

Platinum group metals find the widest application in technology and industry.

Platinum is used for the manufacture of laboratory glassware and equipment for chemical laboratories, as insoluble anodes in the production of hydrogen peroxide, perchlorates, etc., as a protective coating for cladding reactors used in the production of highly pure products, in the processing of fluorine-containing materials, in the food industry. Platinum catalysts are used in basic chemistry for hydrogenation and dehydrogenation reactions, reduction of nitro compounds and halogen compounds, in the production of sulfuric acid by contact method, in the production of hydrocyanic acid, as well as in the processes of pyrolysis of gaseous hydrocarbons, catalytic polymerization, hydrogenation, alkylation, cracking and reforming. sulfur removal processes.

In the production of ammonia and nitric acid, catalyst meshes made of alloys of platinum with rhodium and palladium are used, and in the production of hydrocyanic acid, meshes made of a platinum alloy with rhodium are used. When hydrogenating cellulose or polysaccharides, ruthenium is used as a catalyst, and when hydrogenating some organic compounds, osmium is used. Palladium coatings are used to make vessels for the distillation of hydrofluoric acid.

Platinum, platinum metals and their alloys are widely used in the manufacture of contacts, cathodes and anticathodes of X-ray tubes, electrical resistances, fuses, parts of astronomical instruments, communication equipment, thermocouples.

The high reflectivity of rhodium is used to coat reflectors. Ruthenium coatings applied to tungsten filaments significantly increase their service life. Ruthenium is also used in instrument making in the manufacture of parts requiring high strength. A palladium alloy with 18% 1g has great elasticity, so spring contacts are made from it in aircraft instrumentation. Alloys of osmium with iridium are used in instrument making for the manufacture of some parts of marine precision instruments. Powerful permanent magnets are made from a platinum-cobalt magnetic alloy.

Platinum group metals (PGMs)

Platinum group metals, or platinoids, are 6 precious chemical elements of a noble appearance. They are located in the periodic table in one row and are transition metals of 8-10 groups of 5-6 periods. Externally, the metals are similar to each other.

Platinum group metals include:

- Platinum.

- Palladium.

- Rhodium.

- Ruthenium.

- Iridium.

- Osmium.

The main features of the platinum group metals are:

- silver-gray tint, except osmium (white-blue);

- crystalline properties that help accelerate chemical processes;

- catalysts that control the rate of oxidation and hydrogenation reactions;

- chemically resistant metals to the action of many reagents;

- have high electrical conductivity;

- withstand high temperatures;

- infusibility.

The main sources of platinum metals are rare element minerals. Today, precious platinum metals are used in jewelry production, but to varying degrees, and biologically active compounds of platinum metals are used in medicine.

Platinum

Platinum has been known since ancient times, and the name comes from the Spanish language: “little silver.” The conquistadors were the first Europeans to become acquainted with platinum in the mid-16th century in South America. And in 1735, the king of Spain issued a decree according to which platinum should be drowned in the river and not brought into the country.

Later the river was named Platino del Pinto. The decree was repealed only forty years later, for the falsification of gold and silver coins by the Madrid authorities. Later, alchemists became acquainted with platinum, but considered it unsuitable. But in France it still found its use in the form of a standard meter and then a kilogram.

In Russia, the metal was called white gold, having been found in placer gold.

Platinum is one of the rarest metals, because its content in the earth's crust is low. The main deposits of platinum are: Russia, USA (2 large mines: Stillwater, East Bouder), China, Zimbabwe (9 tons), South Africa (Bushwell complex).

In Russia, this PGM metal has a unique base, with a huge number of deposits, the main of which is located in Zarechensk (Murmansk region).

Platinum mining is a labor-intensive process, of two types:

- Open mining method: in secondary placer deposits. There, platinum is concentrated as a result of the destruction of the primary rock.

- Closed mining method: in primary deposits, with the construction of mines, drilling holes in rocks, laying explosives and the explosion itself.

Platinum is a precious metal used in jewelry and industry. The properties of platinum are wide:

- heavier than gold and silver;

- does not oxidize;

- does not react with other elements when heated;

- ductile metal;

- has good electrical conductivity;

- does not dissolve under the influence of acids;

- high melting point;

- good malleability.

The scope of platinum is quite wide and is not limited to jewelry production, because it has unique beauty and nobility. Currently, the price of metal is growing, as it is also used in industry. So, the uses of platinum:

- jewelry production, for the manufacture of various types of jewelry;

- medicine;

- chemical industry;

- shipbuilding;

- aircraft manufacturing;

- space sphere;

- glass industry;

- banking.

Palladium

Today, palladium is the most expensive platinum group metal used in industry.

In the late 17th century, Brazilian mining workers found an alloy with similar gold or platinum content. The chemist W. Wollaston worked on the interaction of crude platinum with hydrochloric and nitric acids, and the addition of mercuric cyanide. Afterwards a yellow precipitate fell, which he heated with sulfur and borax. Having received balls of metal and calling the metal palladium.

The metal was named after the asteroid. This platinum group metal is found very rarely in nature in its pure form. And more often in combination with other metals (gold, silver, platinum).

Metal is also mined in two ways:

- on indigenous (primary) deposits;

- in placer form, in the form of a nugget, and account for only 2% of all metal production.

Main palladium deposits:

- Canada;

- USA;

- Colombia;

- Austria;

- SOUTH AFRICA.

Palladium mining also occurs in Russia, concentrated in the Urals. The main properties of palladium are:

- low density;

- chemical inertness;

- looks like silver;

- high malleability;

- elasticity, which allows it to be used in the manufacture of jewelry;

- melting point 1555 degrees;

- processable;

- fragile metal under mechanical stress;

- dissolves when exposed to a mixture of sulfuric and nitric acids;

- can form compounds with other chemical elements (boron, chlorine, sulfur, silicon);

- does not react;

- does not oxidize in nature.

Areas of application of palladium

- Jewelry sphere, adding metal to alloys;

- production of catalysts for cars, for afterburning exhaust gases according to EU standards;

- medicine: production of elements for pacemakers, instruments, utensils;

- chemical industry: manufacture of flasks and containers, as well as for hydrogen purification;

- electronic sphere: military aerospace technology;

- investment activity: purchase of bullion.

Rhodium

Following the discovery of palladium, Wollaston discovered another platinum group metal, rhodium, by dissolving crude platinum in aqua regia (a mixture of hydrochloric and nitric acids) and neutralizing the excess acid with caustic soda. Having precipitated platinum with ammonium chloride, palladium with mercury cyanide.

The resulting filtrate was treated with hydrochloric acid (to remove excess mercuric cyanide) and evaporated to dryness. And the sediment treated with alcohol looked like a dark red powder of double sodium hydrogen salt of hydrochloric acid.

And in turn, when the powder was calcined in a stream of hydrogen, metal was obtained.

Rhodium gets its name from the Greek: rose. Rhodium is mined together with platinum/gold. The main sources of rhodium are the gold deposits of Mexico and deposits of rhodium Nevyanskite.

Rhodium is a silver-white metal and belongs to the noble metals of the platinum group.

Properties of rhodium

- Dissolves in hydrogen peroxide, sulfuric acid;

- dissolves when boiled in a mixture of hydrochloric and nitric acids;

- high chemical resistance;

- interacts with non-metals only at red heat temperatures;

- oxidation occurs at high temperature;

- resistant metal to corrosive environments.

Since rhodium is a precious and unique metal, its scope of application is different:

- as a catalyst (catalytic filters for neutralizing exhaust gases);

- is a construction material for the manufacture of mirrors and glass;

- by alloying rhodium with platinum, an effective catalyst is obtained in the production of nitric acid by means of ammonia oxidation with air;

- production of thermocouples (when alloyed with iridium or platinum);

- impart wear resistance and corrosion resistance to jewelry.

Ruthenium

Ruthenium was discovered in Kazan in 1844 by K. Klaus. He analyzed factory platinum deposits from the St. Petersburg Mint. He extracted platinum and some platinum metals from the ore, and then fused the residue with saltpeter, extracting the water-soluble part.

And the sediment, insoluble in water, interacted with aqua regia and dried it out. K. Klaus treated the dry residue after distillation with boiling water and added excess potash. Having separated the precipitate of iron hydroxide, he discovered an element of unknown origin of a dark purple hue in a solution of the precipitate in hydrochloric acid.

Ruthenium was named after Russia (Ruthenia - Russia).

Ruthenium mining always accompanies platinum mining in alluvial and primary deposits. Present as impurities in nickel ore and copper ore. There are also artificial sources of ruthenium mining, i.e. nuclear industry waste. The main deposits of this platinum group metal are South Africa, Canada, Russia, and Zimbabwe.

Main characteristics of ruthenium:

- silver-white shiny or matte color;

- has hardness;

- refractory;

- upon strong calcination in air it passes into the gas phase;

- dissolves slowly with hydrochloric acid at ordinary temperatures, quickly at high temperatures;

- gas absorption capacity.

Scope of metal

- Production of catalysts;

- protective coatings;

- decorative coatings;

- in the form of additives to decorations;

- additive to elite enamels and more.

Iridium

At the beginning of the 19th century, chemists were interested in crude platinum and all the possible elements contained in it. Then Descotilles, Fourcroy and Vauquelin began to study the raw metal, alloying it with caustic potassium, obtaining compounds of unknown metals that were partially soluble in water. Tennant followed the same method, and was able to isolate two new metals: iridium and osmium.

Iridium got its name from the Greek: rainbow, due to the fact that the compounds of this metal were painted in different colors. Osmium, due to the dissolution of the alkaline osmiridium alloy in acid (or water), was accompanied by a strong odor. From the Greek language, receiving the name: smell.

Iridium is a very rare platinum group metal that is almost impossible to obtain. Its extraction is accompanied by companions: platinum or osmium and ruthenium or palladium. It is found in copper and nickel ores. Place of iridium production: Canada (British Columbia), USA (California), South Africa (Transvaal), Tasmania Island, New Guinea, Kalimantan Island.

Characteristics of iridium:

- beautiful white-silver metal;

- hard and durable metal;

- high density and strength;

- the effects are carried out by heating the metal;

- strengthens any composition, making it wear-resistant;

- chemical resistance;

- resistant to corrosion;

- resistance to oxidation and all types of destruction, even under the influence of temperature.

Application area:

- chemical industry;

- jewelry making;

- together with other metals, it is a component for car spark plugs;

- alloys with iridium are used in medicine and for the production of instruments;

- In scientific activities, metal is not in great demand.

Osmium

Pure osmium does not exist in nature; it is found in a complex with rhodium. Osmium deposits are concentrated in: Africa (south), Tasmania, Australia, USA, Canada, Russia, Colombia, South Africa (the largest reserves).

Characteristics of osmium:

- silver-blue crystals;

- pungent odor when interacting with substances;

- insoluble in alkalis and acids, mixtures of hydrochloric and nitric acids;

- chemical inertness;

- Powdered osmium is a raw material for products, slowly susceptible to dissolution;

- hard and brittle;

- refractory;

- high density: the heaviest metal.

Application area

- Medicine: pacemakers, implants;

- industry: for measuring equipment, watch movements;

- Tetraosmium oxide is used in electron microscopy.

Platinum group metals are rare and unique metals that are not so often found in nature, but are widely and actively used in various spheres of life, thereby helping humanity.

Physical properties of platinum metals

The physical properties of the platinum group metals are very similar to each other. These are very refractory and low-volatile metals of light gray color of different shades. Based on their density, platinum metals are divided into light (ruthenium, rhodium, palladium) and heavy (osmium, iridium, platinum). The heaviest metals are osmium and iridium, the lightest is palladium.

Platinum, palladium, rhodium and iridium crystallize into face-centered cubic (fc) lattices. The crystal lattices of osmium and ruthenium are hexagonal with rotary packing. When salt solutions are exposed to reducing agents, platinum metals can be obtained in the form of “black”, which is highly dispersed.

The boiling and melting points of metals in both triads decrease from left to right - from ruthenium to palladium and from osmium to platinum, and from bottom to top vertically in the periodic table. The most refractory are osmium and ruthenium, the most fusible is palladium. The boiling points of platinum metals are very high. However, when calcined in air, ruthenium gradually and osmium quickly evaporate due to the formation of volatile tetroxides. Volatilization of platinum (starting from 1000 °C), iridium (from 2000 °C) and rhodium, explained by the formation of volatile oxides, is also observed.

Osmium, ruthenium, iridium and rhodium are very hard and brittle. Osmium has the greatest hardness, but it can also be ground into powder. Rhodium is almost as difficult to process as osmium, iridium only at red heat. When hot, platinum can be easily rolled and welded. Soft and ductile palladium is especially easy to machine. Rhodium and iridium have the greatest thermal and electrical conductivity.

A characteristic property of platinum metals is the ability to absorb certain gases on the surface, especially hydrogen and oxygen. The tendency to absorption increases significantly for metals in finely dispersed and colloidal states.

The greatest ability to absorb hydrogen is inherent in palladium: 1 volume of palladium at room temperature can absorb up to 900 volumes of hydrogen. When a certain volume of hydrogen is absorbed, the crystal lattice of palladium expands, as solid solutions of hydrogen are formed in the metal. The absorption capacity with respect to hydrogen decreases in the series: Pd>Ir>Rh>Pt>Ru>Os. Absorbed hydrogen can be removed by heating metals to 100 °C in a vacuum. It is most easily removed from palladium, and more difficult from platinum and, especially, iridium.

Platinum (especially platinum black) absorbs oxygen quite strongly: 100 volumes of oxygen per volume of platinum black. Palladium and other platinum metals absorb oxygen much less.

Due to their ability to absorb gases, platinum metals, mainly palladium, platinum and ruthenium, are used as catalysts for hydrogenation and oxidation reactions. Their catalytic activity increases when using black. Osmium also has high catalytic activity, but osmium catalysts are easily poisoned.

Platinum and its properties

Platinum is a rare, shiny, silver-colored metal. It occupies a special place among other precious metals, being usually more expensive than gold and silver.

This is due to the fact that mining platinum is an extremely labor-intensive process and this metal is very rare. For example, to obtain one ounce of gold, it is enough to refine three tons of ore, but to extract the same amount of platinum, you need to process up to ten tons of rock.

History of metal use

Platinum was known even before our era. It was used in Ancient Egypt to make a variety of jewelry. It was also common among the Incas, but was forgotten over time. In the photo you can see platinum items discovered by archaeologists:

Only after a long time, the discovery of this substance occurred thanks to Spanish travelers who were exploring South America. Initially, it was not appreciated, as the name suggests. "Platina" translated from Spanish can be formulated as "little silver."

Accordingly, platinum was valued much less than precious metals. Often it was even considered unripe gold or incorrect silver (due to its color) and was simply thrown away. It is characterized by refractoriness and high density.

Therefore it was considered unsuitable for any use.

However, then an interesting property was discovered - this precious metal has the ability to easily alloy with gold. Jewelers took this into account and actively began to mix platinum into gold products, thereby reducing the cost of their production.

Moreover, this was done so skillfully that it was almost impossible to detect a fake. Due to the high density of platinum, even a small volume of it increased the weight of the finished product, but this was compensated by adding a certain amount of silver to the alloy, which did not affect the color.

Such fraud was nevertheless recognized, and the import of the precious metal into Europe was prohibited by law for some time.

Platinum was recognized as an independent chemical element only in the mid-eighteenth century. A thorough study of its qualities made it possible to find the first use of this metal.

The physical and operational properties of platinum, especially resistance to various influences and high density, served as the basis for making useful equipment from it. In particular, platinum retorts were successfully used to concentrate caustic sulfuric acid.

Such vessels were initially made by forging or pressing, since in those days scientific progress could not provide the necessary temperature in furnaces for melting. By the end of the nineteenth century, it was possible to melt platinum using the flame generated by the combustion of detonating gas.

Platinum in Russia

The history of this noble metal in Russia dates back to 1819, when it was first found in the Urals, near Yekaterinburg. Five years later, platinum deposits were found in the Nizhny Tagil district. The placers turned out to be so abundant that Russia quickly became the leader in production throughout the world.

In the photo you can see the largest nugget mined at these deposits:

Its weight was 12 kg (unfortunately, it was later melted down).

Ural platinum was actively purchased by foreign companies; exports especially increased after an industrial method was developed to purify it from impurities and create pure silver-colored ingots. Initially, it was in great demand abroad in England and France, later joined by the USA and Germany.

During the research process, scientists discovered some elements that make up native platinum. Palladium and rhodium were the first to be added to Mendeleev's periodic table, later iridium and osmium were isolated. And the final element included in the platinum group was ruthenium, discovered in 1844.

Due to the fact that the volumes of platinum mined in the Urals were extremely high and most of the metal simply did not find worthy use, in 1828 a decision was made to issue platinum coins. The photo shows the first Russian-made coins made of this precious metal.

By that time, a way had already been found to produce various high-quality products. This method, called powder metallurgy, is still widely used today. At the moment, Russian coins of the 19th century made of platinum are of enormous value. The cost of one copy can reach up to $5,000.

Most of the mined platinum was used to make jewelry until the mid-twentieth century, after which it began to be used more often for technical purposes. It is used in the following industries:

- Automotive industry (for the manufacture of catalysts);

- Electrical engineering (creation of elements for electric furnaces exposed to high temperatures);

- Petrochemical and organic synthesis;

- Ammonia synthesis.

It is also used in the manufacture of parts for glass furnaces, various laboratory equipment, and equipment for industries where resistance to chemical and temperature influences is required.

Basic properties

You can often hear the opinion that platinum and white gold are one and the same. But in fact, such a statement is fundamentally wrong; they are similar only in color.

Platinum is a chemical element of the periodic table (a natural classification of elements based on the electronic structure of atoms), with its own characteristic properties. Although in the photo you can see some resemblance to white gold in appearance.

It is a silver-colored precious metal, but it still looks a little different than silver. It also differs from others in its characteristics and methods of application.

Physical and chemical properties of platinum

This element is a refractory metal with high density; a temperature of 1769 degrees Celsius is required for its melting, and 3800 degrees for boiling, which is due to low thermal conductivity.

It is also one of the heaviest metals on the periodic table. In this indicator, it is surpassed only by two other elements of the platinum group - osmium and iridium. The density under normal conditions is 21.45 grams per square decimeter. Specific gravity – 21.45 grams per cubic centimeter. This figure is higher than that of gold and is almost twice the specific gravity of silver.

The hardness of platinum is another quality due to which it is used in industry and jewelry. Resistance to various external influences makes the process of processing and manufacturing products more labor-intensive, but its operational properties more than compensate for such inconveniences.

For example, jewelry can be made entirely of pure platinum, while gold and silver require other materials to ensure strength.

It is also worth noting the high ductility of this metal. It can be used to make the thinnest sheet of foil or light wire without losing its basic properties.

Platinum is part of the group of noble metals, as it does not oxidize and resists corrosion. The high inertness of the metal does not allow it to interact with acids or alkalis. It can be dissolved only in aqua regia and liquid bromine, and is susceptible to dissolution under prolonged exposure to hot sulfuric acid.

When this substance is heated, the possibility of interaction with other chemical elements, substances and alloys increases. Increasing the temperature allows platinum oxide to form on the surface of the metal. There are several varieties of it that are easy to distinguish by color.

The most famous are:

- Black PtO (dark grey);

- Platinum oxide PtO2 (brown);

- PtO3 oxide (red-brown).

The speed and degree of oxidation of this metal directly depends on how freely oxygen reaches the surface and what its pressure is. Other metals located on the surface of platinum can serve as an obstacle to oxidation. Therefore, the greatest oxidation should be expected from pure metal without any impurities.

Depending on the specific compound, platinum can exhibit varying degrees of oxidation. This indicator varies from 0 to +8.

Possessing a fairly low resistivity, this metal is a good conductor, inferior in this property to aluminum, copper and silver. The resistivity indicator is close to iron.

Accordingly, the specific conductivity of platinum (the reciprocal of resistivity) occupies a similar position among other elements of the periodic table.

Since it is a conductor, its resistivity increases as it heats up, while its conductivity, on the contrary, decreases.

This property is due to the fact that the particles in the platinum composition begin to move in a chaotic manner as the temperature increases. And this, in turn, creates obstacles to the passage of electric current.

One of the most important qualities, which is widely used in production, is the property of this noble metal to act as a catalyst for numerous chemical reactions. It is usually used in an alloy with rhodium or as platinum black - a fine powder of a characteristic black color obtained by reducing compounds.

Platinum resistance thermometers are quite widespread nowadays (illustrated in the photo).

This is due to the fact that this substance is practically not subject to corrosion, has a high degree of ductility, inertness and makes it possible to use pure metal for production.

Qualities such as high resistivity and a significant temperature coefficient of resistance also play an important role.

Conclusion

Most people think of platinum as a very expensive, silvery-white metal that is used to make jewelry. However, due to its numerous properties, it has become widespread in various fields of human activity, from medicine to the automotive industry.

Although platinum has never been used as money in its history, investing in platinum is considered a fairly profitable investment. One ounce of this metal exceeds the value of a similar amount of gold by $270. If you constantly monitor the exchange rate of precious metals, you can make a good profit.

General characteristics of platinum metals

The general name of platinum metals combines the elements of the second and third triads of the eighth group of the periodic table: ruthenium, rhodium, palladium, osmium, iridium and platinum. These elements form a group of rather rare metals, similar in their properties to each other, so separating them presents significant difficulties.

In nature, platinum metals occur almost exclusively in the native state, usually all together, but never in iron ores.

Platinum metals are low-active and very resistant to chemical influences. Some of them are insoluble not only in acids, but also in aqua regia.

Osmium crystals

Ruthenium, rhodium, osmium and iridium are refractory. Despite their low availability and high cost, these metals, along with platinum, have versatile technical applications that are increasing year by year.

Although platinum metals can exhibit different oxidation states in compounds, they are especially typical of compounds in which their oxidation state is +4. Osmium and ruthenium are also characterized by compounds with the oxidation state of these elements +8.

Osmium (VIII) oxide, or osmium tetroxide, OsO 4 is the most stable of the oxides of this element. It is slowly formed even when osmium is stored in air and is a low-melting (melting temperature 41 o C) crystals of pale yellow color. OsO4 vapors have a pungent odor and are very poisonous.

Osmium tetroxide dissolves quite well in water, and its solution does not give an acidic reaction to litmus. However, as was first established by L.A. Chugaev (1918), OsO4 forms fragile complex compounds with strong alkalis.

Possessing pronounced oxidizing properties, OsO4 reacts vigorously with organic substances, being reduced to black osmium dioxide OsO2. This is the basis for the use of OsO4 for staining microscopic preparations.

Ruthenium crystal

VIII oxide or ruthenium tetroxide, RuO4 , are solid crystals of golden yellow color, melting at 25.4 o C and soluble in water. Ruthenium tetroxide is much less stable than OsO4, and at a temperature of about 108 o C (below the boiling point) it decomposes explosively into RuO2 and oxygen.

Osmium fluoride (VIII), or osmium octafluoride, OsF8 is obtained by direct combination of osmium with fluorine at 250 o C in the form of colorless vapors, which condense upon cooling into lemon-yellow crystals with a melting point of 34.4 o C.

Osmium octafluoride exhibits pronounced oxidizing properties. With water it gradually decomposes into osmium tetroxide and hydrogen fluoride:

OsF8 + 4H2O = OsO4 + 8HF

All platinum metals exhibit a pronounced tendency to form complexes.

Platinum. Platinum has been known in South America since pre-Columbian times. This metal is similar in color and shine to silver, which is why the Spaniards, who conquered most of the continent, called it platinum (Spanish platina - a diminutive of plata - “silver”). The properties of platinum were described by the Spanish officer Don Antonio de Ulloa in 1748.

Platinum crystal

In nature, platinum, like gold, is found in placers in the form of grains, always containing impurities of other platinum metals.

Platinum is a white, shiny, malleable metal that does not change in air even when heated. Some acids have no effect on it. Platinum dissolves in aqua regia, but is much more difficult to dissolve than gold.

In the chemical industry, platinum is used to make corrosion-resistant equipment parts. Platinum anodes are used in a number of electrochemical industries (production of persulfuric acid, perchlorates, perborates). Platinum is widely used as a catalyst, especially when carrying out redox reactions. It represents the first heterogeneous catalyst known since the beginning of the 19th century. Currently, platinum catalysts are used in the production of sulfuric and nitric acids, in the purification of hydrogen from oxygen impurities and in a number of other processes. Platinum is used to make heating elements for electric furnaces and temperature measuring instruments (resistance thermometers and thermocouples). In a highly dispersed state, platinum dissolves significant amounts of hydrogen and oxygen. The use of platinum for the manufacture of a hydrogen electrode is based on its ability to dissolve hydrogen.

In most of its compounds, platinum exhibits oxidation states of +2 and +4. In both states, it has a pronounced ability to form complex compounds; Platinum(IV) compounds are more important.

When platinum is dissolved in aqua regia, hexachloroplatinum, or hydroplatinic acid, H2[PtCl6] is obtained, which, when the solution is evaporated, is released in the form of red-brown crystals of the composition H2[PtCl6] •6H2O. The potassium salt of this acid is one of the least soluble potassium salts. Therefore, its formation is used in chemical analysis to discover potassium.

When heated in a stream of chlorine to 360 °C, hexachloroplatinic acid decomposes with the release of hydrogen chloride and the formation of platinum (IV) chloride PtCl4.

If alkali is added to a solution of H2[PtCl6], a brown precipitate forms. This substance is called platinic acid, since when dissolved in excess alkali it forms a salt. Platinum (IV) oxide PtO2 is also known.

II ) chloride is produced by passing chlorine over finely crushed platinum. It has a greenish color and is insoluble in water.

Complex compounds of platinum (II) include, for example, salts of tetracyanoplatinic (P) acid H2[Pt(CN)4]. The barium salt of this acid, Ba[Pt(CN)4], exhibits bright fluorescence when exposed to ultraviolet and x-rays and is used in fluoroscopy to cover fluorescent screens.

Palladium (Pall adium ). Iridium (lridium). Palladium is a silvery-white metal, the lightest of the platinum metals, the softest and most malleable. It is remarkable for its ability to absorb huge amounts of hydrogen (up to 900 volumes per 1 volume of metal). In this case, palladium retains its metallic appearance, but significantly increases in volume, becomes brittle and easily forms cracks. The hydrogen absorbed by palladium is apparently in a state approaching the atomic state and is therefore very active. A palladium plate saturated with hydrogen converts chlorine, bromine and iodine into hydrogen halides, reduces iron (III) salts into iron (II) salts, mercury (II) salts into mercury (I) salts, and sulfur dioxide into hydrogen sulfide.

Palladium coin

Some types of laboratory glassware, as well as parts of equipment for separating hydrogen isotopes, are made from palladium. Palladium-silver alloys are used in communication equipment, in particular, for the manufacture of contacts. Temperature regulators and thermocouples use alloys of palladium with gold, platinum and rhodium. Some palladium alloys are used in jewelry and dental practice.

When deposited on asbestos, porcelain, or other supports, palladium serves as a catalyst for a series of redox reactions. This property is used both in the laboratory and in industry in the synthesis of certain organic compounds. Palladium catalyst is used to purify hydrogen from traces of oxygen, as well as oxygen from traces of hydrogen.

Chemically, palladium differs from other platinum metals by being significantly more active. When heated red-hot, it combines with oxygen to form PdO oxide and dissolves in nitric acid, hot concentrated sulfuric acid and aqua regia.

Like platinum, palladium has oxidation states of +2 and +4; palladium(II) compounds are more stable. Most palladium salts are soluble in water and are highly hydrolyzed in solutions. Palladium (II) chloride PdCl2 is very easily reduced in solution to metal by some gaseous reducing agents, in particular carbon monoxide (II), which is the basis for its use for the discovery of carbon monoxide in gas mixtures. It is also used as a catalyst for some redox reactions.

Iridium

Iridium differs from platinum in having a very high melting point and even greater resistance to various chemical influences. Neither individual acids nor aqua regia affect iridium. In addition, iridium is significantly superior to platinum in its hardness.

Pure iridium is used to make some scientific instruments. For the same purpose, an alloy containing 90% platinum and 10% iridium is used. The international standards of the meter and kilogram are made from this alloy.

Download:

Download free essay on the topic: “Platinum metals” Platinum-metals.docx (211 Downloads)

You can download abstracts on other topics here

Similar

Platinum group metals: list, prices, prospects and forms of investment

The platinum group metals have their own name - “platinoids”. The platinum group metals include six precious metals, namely platinum, palladium, rhodium, ruthenium, iridium and osmium.

The common characteristic of all these precious metals is that they are silvery-white in color and have catalytic properties that allow them to speed up chemical reactions.

These precious metals are chemically resistant, highly electrically conductive, and can withstand fairly high temperatures. The features, forms, prospects of investments, as well as the pricing policy of these precious metals will be discussed in more detail in this article.