Welcome to our page. Today we will talk about alloys of precious metals with common ones, their properties, color and qualities important for jewelry. Already at the dawn of mankind, gold was ubiquitous. It was used as the first currency, decorated the armor of warriors and made valuable jewelry. Working with metal was easy, expensive jewelry and coins were a measure of wealth and influence.

Today, jewelers use gold alloys with new additives, and sophisticated shades give jewelry a special originality.

Why don't jewelers use pure raw materials?

The main reason why gold is not used undiluted is its softness. To prevent gold items from deforming and to increase their wear resistance, additives are used. The shade of the jewelry depends on the ligature and its cost decreases. Heavy 985 gold becomes lighter with a ligature.

Metals used in alloys with gold

Different alloys may differ in shade, just as materials of the same shade can differ in the alloy included in it and the amount of precious metal:

- Silver gives the alloy softness. As the ligature increases, the shade changes from yellow with an admixture of green (30%) to pale lemon (60%).

- Copper is often used by jewelers. The hue changes to red - the color of jewelry, familiar to everyone. Due to reduced corrosion resistance, it is used in combination with a silver alloy.

- With nickel, hardness increases, malleability increases, and magnetic properties appear. The color turns out to be light yellow.

- With palladium the melting point increases. The color changes greatly: with a low additive content (10%) the color is almost white. Rarely used by jewelers due to the refractoriness of the alloy.

- Platinum makes the melting point higher. The material is extremely ductile and less susceptible to corrosion. The color changes sharply; even with the addition of a small amount of alloy (8%), platinum changes the color of the alloy to almost white.

- Ruthenium is a platinum group metal. The name "ruthenia" means "Russia" in Latin. It is added to increase strength. The products are used to treat oncology. The alloy has a black tint.

- Together with iridium, wear resistance increases, the color does not change.

- Osmium imparts refractoriness to the alloy, the material becomes harder, and elasticity increases. The color is characteristic of gold ore.

- An alloy of 22% aluminum and 88% gold is indistinguishable from pure aurum. An alloy of gold and aluminum with the addition of copper has the same color.

- Cadmium makes the substance fusible. As the cadmium content increases, the color changes from yellow to gray. It is practically not used in the jewelry industry: it is an extremely fragile material.

- Zinc colors the alloy in a greenish tint, increasing the fragility of the material. Reduces melting point.

Every year more and more new alloys appear, their results are used in various spheres of life of a modern person.

Interesting facts about gold

Yellow metal is used not only to create jewelry. Gold is also used for the manufacture of mobile phones and other equipment, since it has phenomenal malleability and ductility. Artists could gild their paintings and icons: the metal could be used to produce a sheet less than half a millimeter thick.

This element is also distinguished by its good conductivity of electricity. Therefore, gold is also widely used in the field of microelectronics. They use it to store savings and even for treatment. However, at least half of the countries' total gold reserves go to the jewelry industry. What alloys are added to metal and why?

Who should you definitely not lend money to?

Brand for 8 thousand rubles: a Siberian woman created a profitable business in the sewing business

Point of view: how will people's perceptions change if only robots work?

Colors of gold alloys depending on composition

The color depends on the ratio of the components taken. Jewelry that looks the same can have different prices and properties thanks to extensive research in this area.

Yellow

The classic color is the result of a combination with Cu and Ag. Improves wear resistance. Yellow color in jewelry has been very popular for several centuries. 750 and 585 are typical gold content values for this color.

Black

A very effective color for modern jewelry, it can be obtained in several ways:

- oxidation with cobalt;

- during dressing with the addition of carbon;

- patting;

- Rhodium or ruthenium plating.

White

Color is obtained by adding a variety of ligatures. It can be manganese, nickel, or palladium. Jewelry of this color is very beautiful, white with a yellow undertone. They first began to produce it in the first decade of the 20th century to replace a refractory alloy with platinum.

Red

As a result of combining gold with copper, a pink or red alloy is obtained. This species spread throughout Europe in the 20th century. For Russia, its appearance dates back to the 18th century. Today it is popular as a base in engagement rings.

Other

Greenish-yellow is the result of fusion with a silver ligature. Consists of 73% gold and 27% silver. The name “electrum” came to us from Ancient history as a natural compound. A greenish tint is characteristic of alloys with the addition of cadmium. Jewelry made from such an alloy is considered harmful to health. Due to the toxicity of the ligature, they should not be worn for long periods of time.

When alloyed with indium, it produces a spectacular blue color.

For a long time, jewelers around the world tried to get purple gold. The experiments were successful in 2002. 19 carat (750 carat) purple gold contains additives of aluminum and palladium. It seems difficult to care for such products. The material is very fragile and is used in jewelry only as individual elements.

Gold Alloy Components

Each sample corresponds to a certain content of various metals in the final alloy. These components give the gold alloy certain properties:

- Silver enhances ductility, malleability and significantly changes color. If the alloy contains 30% silver, a lighter shade appears. An alloy becomes white when it contains more than 65 percent of this metal.

- The copper content makes gold harder. However, in this case it is more susceptible to corrosion. It is copper that makes gold reddish. The higher its content, the brighter the color.

- Cadmium gives gold fusible properties, the alloy gets a greenish tint.

- Zinc can be one of the components of white gold. Partially reduces the melting point.

- Palladium colors the gold alloy white with a beige tint.

- Nickel in the white gold alloy gives it hardness and a light yellow tint.

- Platinum adds elasticity. Eight percent of this metal is enough to discolor the gold alloy.

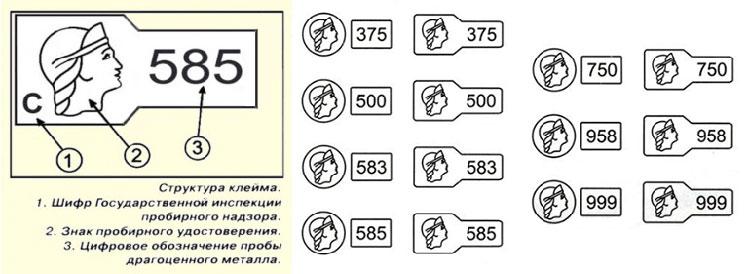

Alloy markings

Gold-containing alloys have a common marking. It is based on the designation in Cyrillic letters:

- Zl – gold;

- Pd – palladium;

- Pl – platinum;

- Kd – cadmium;

- Wed – silver;

- M – copper;

- N – nickel;

- C – zinc.

Next to the letters indicating the metal is a number indicating the percentage of the material contained. For precious metals, the content is indicated in fractions of a thousand, for the rest - in hundredths, that is, as a percentage.

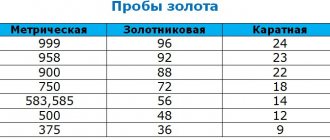

Alloy sampling systems

Previously, countries had different valuation systems for precious metals. With the development of progress, their number has decreased. Today we know what systems there are - metric and carat.

Metric

It is more widespread than others in the world and the only one operating today in Russia. The principle of the system is to indicate the amount of gold per kilogram of material. According to this system, the most common samples are 375, 500, 750, 958 and 999.

Carat

The karate system is widely used in Europe and the USA. It contains 24 parts (carats) corresponding to 100% precious metal content. For example, a 10K hallmark means that out of 24 parts of the alloy, 10 are pure gold.

Zolotnikovaya

The system was used in Tsarist Russia and was abolished in 1927. It was based on the use of a unit of weight - the pound. One pound is 450 grams, or 96 spools. A metal with a purity of at least 36 spools was considered precious.

Lotovaya

The system was used in Old Europe. Back in the Middle Ages, silver and gold were measured in marks. One mark was equal to 16 lots. An alloy with a purity of at least 6 lots is considered precious, which corresponds to 375 purity.

Table 1. Correspondences of gold samples

| Zolotnikovaya | Metric | Lotovaya | Carat |

| 36 | 375 | 6 | 9 |

| 48 | 500 | 7 | 10 |

| 56 | 585 | 9 | 14 |

| 72 | 750 | 12 | 18 |

Table 2. Names of alloy, composition and colors of 583 samples

| № | Alloy name | Gold content, % | Silver content, % | Copper content,% | Nickel content, % | Content Other metals, % | Alloy color |

| 1 | ZlM583 | Au 58.3 | — | Cu 41.7 | — | — | bright red |

| 2 | ZlSrM583-20 | Au 58.3 | Ag 2.0 | Cu 39.7 | — | — | bright red |

| 3 | ZlSrM583-42 | Au 58.3 | Ag 4.2 | Cu 37.5 | — | — | bright red |

| 4 | ZlSrM583-80: | Au 58.3 | Ag 8.0 | Cu 33.7 | red | ||

| 5 | ZlSrM583-125 | Au 58.3 | Ag 12.5 | Cu 29.2 | — | — | red |

| 6 | ZlSrM583-146 | Au 58.3 | Ag 14.6 | Cu 27.1 | — | — | red |

| 7 | ZlSrM583-200 | Au 58.3 | Ag 20.0 | Cu 21.7 | — | — | reddish |

| 8 | ZlSrM583-217 | Au 58.3 | Ag 21.7 | Cu 20.0 | — | — | pale red |

| 9 | ZlSrM583-250 | Au 58.3 | Ag 25.0 | Cu 16.7 | — | — | greenish |

| 10 | ZlSrM583-300 | Au 58.3 | Ag 30.0 | Cu 11.7 | — | — | green |

| 11 | ZlSrM583-337 | Au 58.3 | Ag 33.7 | Cu 8.0 | — | — | green |

| 12 | ZlSr583-417 | Au 58.3 | %; Ag 41.7 | — | — | — | green |

| 13 | ZlSrMN3.2-35.7-2.8 | Au 58.3 | Ag 3.2 | Cu 35.7 | Ni 2.8 | — | pink |

| 14 | ZlMN35.4-6.3 | Au 58.3 | — | Cu 35.4 | Ni 6.3 | — | |

| 15 | ZlMN24.7-17 | : Au 58.3 | — | Cu 24.7 | %; Ni 17.0 | — | pale pink |

| 16 | ZlSrPd23.7-18 | Au 58.3 | Ag 23.7 | — | — | Pd 18.0 | white |

| 17 | ZlMNTs23.5-12.2-6 | Au 58.3 | Cu 23.5 | — | — | Ni 12.2 Zn 6.0 | white |

GOST 30649-99. Alloys based on precious metals for jewelry. Brands (with Changes N 1, 2)

GOST 30649-99

Group B51

INTERSTATE STANDARD

JEWELERY ALLOYS BASED ON PRECIOUS METALS

Stamps

Noble metals based alloys for jewellery. Marks

MKS 39.060; 77.120.99* _______________ * Amended edition, Rev. N 1. Date of introduction 2000-07-01

Preface 1 DEVELOPED by the Technical Committee for Standardization TC 304 “Precious metals, alloys, industrial and jewelry products made from them; secondary resources containing precious metals”, Yekaterinburg Non-Ferrous Metals Processing Plant

INTRODUCED by Gosstandart of Russia 2 ACCEPTED by the Interstate Council for Standardization, Metrology and Certification (Protocol N 15-99 of May 28, 1999)

The following voted for adoption:

| State name | Name of the national standardization body |

| Azerbaijan Republic Republic of Moldova Russian Federation Turkmenistan | Azgosstandart Moldovastandart Gosstandart of Russia Main State Inspectorate of Turkmenistan |

3 This standard takes into account the indicators and requirements of the international standard ISO 9202-91 “Jewelry. Samples of noble metals in alloys” in terms of samples (content of noble metals in alloys) 4 By Decree of the State Committee of the Russian Federation for Standardization and Metrology dated October 19, 1999 N 354-st, the interstate standard GOST 30649-99 was put into effect directly as a state standard Russian Federation from July 1, 2000 5 INTRODUCED FOR THE FIRST TIME

AMENDED Change No. 1, adopted by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 26 of 12/08/2004). Developer state Russia. By order of the Federal Agency for Technical Regulation and Metrology dated March 30, 2005 N 70-st, it came into force on the territory of the Russian Federation from September 1, 2005; Change No. 2, adopted by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 34 of December 11, 2008). Developer state Russia. By order of the Federal Agency for Technical Regulation and Metrology dated July 16, 2009 N 248-st, it came into force on the territory of the Russian Federation from January 1, 2010

Changes No. 1, 2 were made by the database manufacturer according to the text of IUS No. 6, 2005, IUS No. 10, 2009

1 area of use

This standard establishes grades of gold, silver, alloys based on precious metals: gold, silver, platinum and palladium, used for the manufacture of jewelry, ritual and other products for household purposes, semi-finished products for their production in the form of sheets, ribbons, strips, foil, wires, pipes, profiles, cast pieces in any form, produced by hot, cold deformation or casting.

(Changed edition, Amendment No. 2).

2 Normative references

This standard uses references to the following standards:

GOST 12550.1-82 Palladium-iridium alloys. Palladium determination method

GOST 12550.2-82 Palladium-iridium alloys. Spectral analysis methods

GOST 12551.1-82 Platinum-copper alloys. Methods for determining copper

GOST 12551.2-82 Platinum-copper alloys. Spectral analysis methods

GOST 12553.1-77 Platinum-palladium alloys. Palladium determination method

GOST 12553.2-77 Platinum-palladium alloys. Spectral analysis method

GOST 12556.1-82 Platinum-rhodium alloys. Rhodium determination method

GOST 12556.2-82 Platinum-rhodium alloys. Spectral analysis methods

GOST 12558.1-78 Palladium-silver alloys. Silver determination method

GOST 12558.2-78 Palladium-silver alloys. Spectral analysis methods

GOST 12559.1-82 Platinum-iridium alloys. Iridium determination method

GOST 12559.2-82 Platinum-iridium alloys. Spectral analysis methods

GOST 12560.1-78 Palladium-silver-cobalt alloys. Method for determination of cobalt and silver

GOST 12560.2-78 Palladium-silver-cobalt alloys. Spectral analysis method

GOST 12561.1-78 Palladium-silver-copper alloys. Method for determination of copper and silver

GOST 16321.1-70 Silver-copper alloys. Method for determining the mass fraction of silver

GOST 16321.2-70 Silver-copper alloys. Spectral analysis method

GOST 17234-71 Gold alloys. Method for determining the mass fraction of gold and silver

GOST 17235-71 Gold alloys. Spectral method for determining the mass fraction of bismuth, antimony, lead and iron

GOST 22864-83* Noble metals and their alloys. General requirements for analysis methods

GOST 27973.0-88* Gold. General requirements for analysis methods

GOST 27973.1-88 Gold. Atomic emission analysis methods

GOST 27973.2-88 Gold. Induction plasma atomic emission analysis method

GOST 27973.3-88 Gold. Atomic absorption analysis method

GOST 28353.0-89* Silver. General requirements for analysis methods

GOST 28353.1-89 Silver. Atomic emission analysis method

GOST 28353.2-89 Silver. Induction plasma atomic emission analysis method

GOST 28353.3-89 Silver. Method of atomic absorption analysis ________________ * GOST R 52599-2006 “Precious metals and their alloys. General requirements for methods of analysis.”

(Changed edition, Amendment No. 2).

3 Symbols and abbreviations

3.1 The standard adopts the following symbols for grades of alloys and abbreviations: Zl - gold, Sr - silver, Pl - platinum, Rd - rhodium, I - iridium, Pd - palladium, M - copper, N - nickel, C - zinc, Kd – cadmium, Re – rhenium, Kr – silicon, Ga – gallium, V – tungsten, In – indium, It – yttrium, K – cobalt, Ru – ruthenium, X – chromium, Zr – zirconium. Ost. – the rest. (Changed edition, Amendment No. 1, 2). 3.2 The names of alloy grades consist of letters indicating the components of the alloy and the numbers following them. The numbers after the letters indicate the nominal content of the alloy component in thousandths (samples) if the component is a noble metal, and in percent if the component is a base metal. The last component in the brand name is not indicated by a number if it is base. 3.3 Sample - the minimum content of a certain noble metal, measured in parts per thousand units of mass of the alloy.

4 Requirements

4.1 The chemical composition of gold and alloys based on gold, silver, platinum and palladium must meet the requirements of tables 1-4.

Note - By agreement with the authorities of the State Assay Office of the manufacturing country, the manufacture of alloys of other chemical compositions is allowed.

Table 1 - Chemical composition of gold and gold-based alloys

| Brand | Try | Mass fraction of component, %* | |||

| Gold | Silver | Platinum | Palladium | ||

| ZlSrM 375-20 | 375 | 37,5-38,0 | 1,7-2,3 | – | – |

| ZlSrM 375-100 | 37,5-38,0 | 9,5-10,5 | – | – | |

| ZlSrM 375-160 | 37,5-38,0 | 15,5-16,5 | – | – | |

| ZlSrM 375-250 | 37,5-38,0 | 24,5-25,5 | – | – | |

| ZlSrPdM 375-100-38 | 37,5-38,0 | 9,5-10,5 | – | 3,5-4,1 | |

| ZlSrM 500-100 | 500 | 50,0-50,5 | 9,5-10,5 | – | – |

| ZlSr 585-415 | 585 | 58,5-59,0 | Ost. | – | – |

| ZlSrM 585-80 | 58,5-59,0 | 7,5-8,5 | – | – | |

| ZlSrM 585-200 | 58,5-59,0 | 19,5-20,5 | – | – | |

| ZlSrM 585-300 | 58,5-59,0 | 29,5-30,5 | – | – | |

| ZlSrPd 585-255-160 | 58,5-59,0 | 25,0-26,0 | – | Ost. | |

| ZlSrPdTs 585-287-100 | 58,5-59,0 | 28,2-29,2 | – | 9,5-10,5 | |

| ZlSrPdKd 585-280-100 | 58,5-59,0 | 27,5-28,5 | – | 9,5-10,5 | |

| ZlSrNTsM 585-80-8.2-2.5 | 58,5-59,0 | 7,5-8,5 | – | – | |

| ZlNTsM 585-12.5-4 | 58,5-59,0 | – | – | – | |

| ZlSr 750-250 | 750 | 75,0-75,5 | 24,5-25,5 | – | – |

| ZlSrM 750-125 | 75,0-75,5 | 12,0-13,0 | – | – | |

| ZlSrM 750-150 | 75,0-75,5 | 14,5-15,5 | – | – | |

| ZlSrNTs 750-150-7.5 | 75,0-75,5 | 14,5-15,5 | – | – | |

| ZlSrPd 750-100-150 | 75,0-75,5 | 9,5-10,5 | – | Ost. | |

| ZlSrPlM 750-80-90 | 75,0-75,5 | 7,5-8,5 | 8,5-9,5 | – | |

| ZlSrPdN 750-90-140 | 75,0-75,5 | 8,5-9,5 | – | 13,5-14,5 | |

| ZlSrPdN 750-70-140 | 75,0-75,5 | 6,5-7,5 | – | 13,5-14,5 | |

| ZlSrPdNKd 750-90-85-4** | 75,0-75,5 | 8,5-9,5 | – | 8,0-9,0 | |

| ZlNTsM 750-7.5-2.5 | 75,0-75,5 | – | – | – | |

| ZlSrM 958-20*** | 958 | 95,8-96,3 | 1,7-2,3 | – | – |

| PLN 999.9**** | 999 | 99.90 (not less) | – | – | – |

End of table 1

| Brand | Try | Mass fraction of component, %* | |||

| Nickel | Copper | Zinc | Cadmium | ||

| ZlSrM 375-20 | 375 | – | Ost. | – | – |

| ZlSrM 375-100 | – | Ost. | – | – | |

| ZlSrM 375-160 | – | Ost. | – | – | |

| ZlSrM 375-250 | – | Ost. | – | – | |

| ZlSrPdM 375-100-38 | – | Ost. | – | – | |

| ZlSrM 500-100 | 500 | – | Ost. | – | – |

| ZlSr 585-415 | 585 | – | – | – | – |

| ZlSrM 585-80 | – | Ost. | – | – | |

| ZlSrM 585-200 | – | Ost. | – | – | |

| ZlSrM 585-300 | – | Ost. | – | – | |

| ZlSrPd 585-255-160 | – | – | – | – | |

| ZlSrPdTs 585-287-100 | – | – | Ost. | – | |

| ZlSrPdKd 585-280-100 | – | – | – | Ost. | |

| ZlSrNTsM 585-80-8.2-2.5 | 7,7-8,7 | Ost. | 2,2-2,8 | – | |

| ZlNTsM 585-12.5-4 | 12,0-13,0 | Ost. | 3,6-4,4 | – | |

| ZlSr 750-250 | 750 | – | – | – | – |

| ZlSrM 750-125 | – | Ost. | – | – | |

| ZlSrM 750-150 | – | Ost. | – | – | |

| ZlSrNTs 750-150-7.5 | 7,0-8,0 | – | Ost. | – | |

| ZlSrPd 750-100-150 | – | – | – | – | |

| ZlSrPlM 750-80-90 | – | Ost. | – | – | |

| ZlSrPdN 750-90-140 | Ost. | – | – | – | |

| ZlSrPdN 750-70-140 | Ost. | – | – | – | |

| ZlSrPdNKd 750-90-85-4** | 3,5-4,5 | – | – | Ost. | |

| ZlNTsM 750-7.5-2.5 | 7,0-8,0 | Ost. | 2,1-2,9 | – | |

| ZlSrM 958-20*** | 958 | – | Ost. | – | – |

| PLN 999.9**** | 999 | – | – | – | – |

| * Impurities in each grade of alloy should not exceed, %: lead – 0.005; iron – 0.15; antimony – 0.005; bismuth – 0.005; oxygen – 0.007; total – 0.17. ** The alloy contains from 0.008 to 0.040% boron. *** Impurities in the alloy should not exceed, %: lead – 0.003; iron – 0.08; antimony – 0.003; bismuth – 0.003; oxygen – 0.007; total – 0.10. **** Impurities should not exceed, %: lead – 0.003; iron – 0.004; antimony – 0.001; bismuth – 0.002; copper – 0.007; silver – 0.008; total – 0.01. | |||||

______________ * GOST 30649-99 Alloys based on precious metals for jewelry. Brands (with Changes No. 1, 2) Impurities should not exceed, %: lead – 0.003; iron – 0.035; antimony – 0.002; bismuth – 0.002; copper – 0.012; silver – 0.020; total – 0.10.

Table 2 - Chemical composition of silver and silver-based alloys

| Brand | Try | Mass fraction, % | |||||||

| component | impurities, no more | ||||||||

| Silver | Copper | Lead | Iron | Antimony | Bismuth | Oxygen | Total | ||

| SRM 800 | 800 | 80,0-80,5 | Ost. | 0,005 | 0,13 | 0,002 | 0,002 | 0,01 | 0,15 |

| SRM 830 | 830 | 83,0-83,5 | Ost. | 0,005 | 0,13 | 0,002 | 0,002 | 0,01 | 0,15 |

| SRM 875 | 875 | 87,5-88,0 | Ost. | 0,004 | 0,10 | 0,002 | 0,002 | 0,01 | 0,12 |

| SRM 925 | 925 | 92,5-93,0 | Ost. | 0,004 | 0,10 | 0,002 | 0,002 | 0,01 | 0,12 |

| SRM 960 | 960 | 96,0-96,5 | Ost. | 0,004 | 0,08 | 0,002 | 0,002 | 0,01 | 0,10 |

| Wed 999* | 999 | 99.90 (not less) | – | 0,003 | 0,035 | 0,002 | 0,002 | – | 0,10 |

| * For Ср 999, the “Total” column includes the amount of impurities indicated in the table, as well as copper impurities - no more than 0.015%. | |||||||||

Table 3 - Chemical composition of platinum-based alloys

| Brand | Try | Mass fraction of component, %* | ||||

| Platinum | Iridium | Palladium | Rhodium | Copper | ||

| PLI 850-150 | 850 | 85,0-85,5 | Ost. | – | – | – |

| PlPd 850-150 | 85,0-85,5 | – | Ost. | – | – | |

| PlRD 850-150 | 85,0-85,5 | – | – | Ost. | – | |

| PlM 850 | 85,0-85,5 | – | – | – | Ost. | |

| PlPdKr 850-120 | 85,0-85,5 | – | 11,5-12,5 | – | – | |

| PlPdGa 850-140 | 85,0-85,5 | – | 13,5-14,5 | – | – | |

| PLI 900-100 | 900 | 90,0-90,5 | Ost. | – | – | – |

| PlPd 900-100 | 90,0-90,5 | – | Ost. | – | – | |

| PlRd 900-100 | 90,0-90,5 | – | – | Ost. | – | |

| PlM 900 | 90,0-90,5 | – | – | – | Ost. | |

| PlPdRe 900-80** | 90,0-90,5 | – | 7,5-8,5 | – | – | |

| PlPdKr 900-70 | 90,0-90,5 | – | 6,5-7,5 | – | – | |

| Pli 950-50 | 950 | 95,0-95,5 | Ost. | – | – | – |

| PlPd 950-50 | 95,0-95,5 | – | Ost. | – | – | |

| PlRD 950-50 | 95,0-95,5 | – | – | Ost. | – | |

| PlM 950 | 95,0-95,5 | – | – | – | Ost. | |

| PlPdRe 950-25** | 95,0-95,5 | – | 2,0-3,0 | – | – | |

| PlPdKr 950-30 | 95,0-95,5 | – | 2,5-3,5 | – | – | |

| PlV 950 | 95,0-95,5 | – | – | – | – | |

| Pl 990*** | 990 | 99,0-99,5 | – | – | – | – |

End of table 3

| Brand | Try | Mass fraction of component, %* | |||

| Rhenium | Silicon | Gallium | Tungsten | ||

| PLI 850-150 | 850 | – | – | – | – |

| PlPd 850-150 | – | – | – | – | |

| PlRD 850-150 | – | – | – | – | |

| PlM 850 | – | – | – | – | |

| PlPdKr 850-120 | – | Ost. | – | – | |

| PlPdGa 850-140 | – | – | Ost. | – | |

| PLI 900-100 | 900 | – | – | – | – |

| PlPd 900-100 | – | – | – | – | |

| PlRd 900-100 | – | – | – | – | |

| PlM 900 | – | – | – | – | |

| PlPdRe 900-80** | Ost. | – | – | – | |

| PlPdKr 900-70 | – | Ost. | – | – | |

| Pli 950-50 | 950 | – | – | – | – |

| PlPd 950-50 | – | – | – | – | |

| PlRD 950-50 | – | – | – | – | |

| PlM 950 | – | – | – | – | |

| PlPdRe 950-25** | Ost. | – | – | – | |

| PlPdKr 950-30 | – | Ost. | – | – | |

| PlV 950 | – | – | – | Ost. | |

| Pl 990*** | 990 | – | – | – | – |

| * Impurities in each grade of alloy should not exceed %: iron – 0.04; silicon – 0.030; lead – 0.015. ** The alloy contains from 0.01 to 0.10% yttrium. *** The alloy contains from 0.5% to 1.0% titanium. | |||||

Table 4 - Chemical composition of palladium-based alloys

| Brand* | Try | Mass fraction of component, % | ||||||

| Palladium | Iridium | Silver | Ruthenium | Nickel | Copper | Zinc | ||

| PdSrN 500-450 | 500 | 50,0-50,5 | – | 44,5-45,5 | – | Ost. | – | – |

| PdSrKrTsM 500-305-0.8-0.3 | 50,0-50,5 | – | 30,0-31,0 | – | – | Ost. | 0,2-0,4 | |

| PdSrN 850-130 | 850 | 85,0-85,5 | – | 12,5-13,5 | – | Ost. | – | – |

| PdM 850 | 85,0-85,5 | – | – | – | – | Ost. | – | |

| PdKM 850-7.5 | 85,0-85,5 | – | – | – | – | Ost. | – | |

| PdKM 850-10 | 85,0-85,5 | – | – | – | – | Ost. | – | |

| PdNTsM 850-4-1.5 | 85,0-85,5 | – | – | – | 3,5-4,5 | Ost. | 1,0-2,0 | |

| PdNTsinM 850-3.5-1-0.5 | 85,0-85,5 | – | – | – | 3,0-4,0 | Ost. | 0,5-1,5 | |

| PdMKr 850-12 | 85,0-85,5 | – | – | – | – | 11,5-12,5 | – | |

| PdSr 900-100 | 900 | 90,0-90,5 | – | Ost. | – | – | – | – |

| PdI 900-100 | 90,0-90,5 | Ost. | – | – | – | – | – | |

| PdInM 900-5 | 90,0-90,5 | – | – | – | – | Ost. | – | |

| PdKM 900-5 | 90,0-90,5 | – | – | – | – | Ost. | – | |

| PdNTsinM 900-4.5-2-1 | 90,0-90,5 | – | – | – | 4,0-5,0 | Ost. | 1,5-2,5 | |

| PdNTsinM 900-3.5-0.8-0.5 | 90,0-90,5 | – | – | – | 3,0-4,0 | Ost. | 0,5-1,2 | |

| PdMKr 900-8.5 | 90,0-90,5 | – | – | – | – | 8,0-9,0 | – | |

| PdI 950-50 | 950 | 95,0-95,5 | Ost. | – | – | – | – | – |

| PdRu 950-50 | 95,0-95,5 | – | – | Ost. | – | – | – | |

| PdSrM 950-25 | 95,0-95,5 | – | 2,0-3,0 | – | – | Ost. | – | |

| PdSrKGa 950-35-0.8 | 95,0-95,5 | – | 3,0-4,0 | – | – | – | – | |

| PdRe 950 | 95,0-95,5 | – | – | – | – | – | – | |

| PdInM 950-2.5 | 95,0-95,5 | – | – | – | – | Ost. | – | |

| PdKM 950-3 | 95,0-95,5 | – | – | – | – | Ost. | – | |

| PdKin 950-4 | 95,0-95,5 | – | – | – | – | – | – | |

| PdNTsinM 950-2-0.5-0.5 | 95,0-95,5 | – | – | – | 1,5-2,5 | Ost. | 0,3-0,7 | |

| PdMKr 950-3 | 95,0-95,5 | – | – | – | – | 2,5-3,5 | – | |

| PdRUIT 990-5 | 990 | 99,0-99,5 | – | – | 0,3-0,7 | – | – | – |

| PdTsrKh 990-0.7 | 99,0-99,5 | – | – | – | – | – | – | |

| PdNH 990-0.6 | 99,0-99,5 | – | – | – | 0,4-0,8 | – | – | |

| PdVit 990-0.5 | 99,0-99,5 | – | – | – | – | – | – | |

Continued Table 4 – Chemical composition of palladium-based alloys

| Brand* | Try | Mass fraction of component, % | ||||||||

| Cobalt | Rhenium | Gallium | Indium | Zirconium | Tungsten | Silicon | Yttrium | Chromium | ||

| PdSrN 500-450 | 500 | – | – | – | – | – | – | – | – | – |

| PdSrKrTsM 500-305-0.8-0.3 | – | – | – | – | – | – | 0,4-1,2 | – | – | |

| PdSrN 850-130 | 850 | – | – | – | – | – | – | – | – | – |

| PdM 850 | – | – | – | – | – | – | – | – | – | |

| PdKM 850-7.5 | 7,0-8,0 | – | – | – | – | – | – | – | – | |

| PdKM 850-10 | 9,5-10,5 | – | – | – | – | – | – | – | – | |

| PdNTsM 850-4-1.5 | – | – | – | – | – | – | – | – | – | |

| PdNTsinM 850-3.5-1-0.5 | – | – | – | 0,2-0,8 | – | – | – | – | – | |

| PdMKr 850-12 | – | – | – | – | – | – | Ost. | – | – | |

| PdSr 900-100 | 900 | – | – | – | – | – | – | – | – | – |

| PdI 900-100 | – | – | – | – | – | – | – | – | – | |

| PdInM 900-5 | – | – | – | 4,5-5,5 | – | – | – | – | – | |

| PdKM 900-5 | 4,5-5,5 | – | – | – | – | – | – | – | – | |

| PdNTsinM 900-4.5-2-1 | – | – | – | 0,5-1,5 | – | – | – | – | – | |

| PdNTsinM 900-3.5-0.8-0.5 | – | – | – | 0,2-0,8 | – | – | – | – | – | |

| PdMKr 900-8.5 | – | – | – | – | – | – | Ost. | – | – | |

| PdI 950-50 | 950 | – | – | – | – | – | – | – | – | – |

| PdRu 950-50 | – | – | – | – | – | – | – | – | – | |

| PdSrM 950-25 | – | – | – | – | – | – | – | – | – | |

| PdSrKGa 950-35-0.8 | 0,6-1,0 | – | Ost. | – | – | – | – | – | – | |

| PdRe 950 | – | Ost. | – | – | – | – | – | – | – | |

| PdInM 950-2.5 | – | – | – | 2,0-3,0 | – | – | – | – | – | |

| PdKM 950-3 | 2,5-3,5 | – | – | – | – | – | – | – | – | |

| PdKin 950-4 | 3,5-4,5 | – | – | Ost. | – | – | – | – | – | |

| PdNTsinM 950-2-0.5-0.5 | – | – | – | 0,4-0,6 | – | – | – | – | – | |

| PdMKr 950-3 | – | – | – | – | – | – | Ost. | – | – | |

| PdRUIT 990-5 | 990 | – | – | – | – | – | – | – | Ost. | – |

| PdTsrKh 990-0.7 | – | – | – | – | 0,6-0,8 | – | – | – | Ost. | |

| PdNH 990-0.6 | – | – | – | – | – | – | – | – | Ost. | |

| PdVit 990-0.5 | – | – | – | – | – | 0,4-0,6 | – | Ost. | – | |

| * Impurities in each grade of alloy should not exceed %: iron – 0.05; lead – 0.004; bismuth – 0.002. | ||||||||||

Table 4. (Changed edition, Amendment No. 2).

4.2 Chemical composition is determined:

– gold – according to GOST 27973.0 – GOST 27973.3;

– gold-based alloys – according to GOST 17234, GOST 17235, GOST 22864;

– silver – according to GOST 28353.0*, GOST 28353.1, GOST 28353.2, GOST 28353.3;

– silver-based alloys – according to GOST 16321.1, GOST 16321.2, GOST 22864;

– platinum-based alloys – according to GOST 12551.1, GOST 12551.2, GOST 12553.1, GOST 12553.2, GOST 12556.1, GOST 12556.2, GOST 12559.1, GOST 12559.2, GOST 22864.

– palladium-based alloys – according to GOST 12550.1, GOST 12550.2, GOST 12558.1, GOST 12558.2, GOST 12560.1, GOST 12560.2, GOST 12561.1, GOST 12561.2, GOST 22864*. ________________ * GOST R 52599-2006 “Precious metals and their alloys” is in force on the territory of the Russian Federation. General requirements for methods of analysis.”

It is allowed to determine the chemical composition of alloys by other methods that are not inferior in accuracy to standard ones.

(Changed edition, Amendment No. 2). 4.3 Properties of alloys, recommendations for their use are given in Appendices A, B, C, D, E.

What causes metal to tarnish?

There may be several reasons for changing the appearance of a new ring:

- The new product was coated with a polishing compound. In this case, the skin on the finger will also darken. Contamination is easily removed.

- Unfortunately, sometimes a change in the color of a ring may indicate a low content of precious metal. We already know how easily inexpensive alloys can be passed off as jewelry.

- Body jewelry can respond to various changes in the body. Such stains from good jewelry can be easily cleaned.

- Gold deteriorates and becomes stained when exposed to mercury and iodine. We come into contact with the first substance as a last resort, but no one is safe from adding iodine to the water of a public swimming pool. When going to the pool, it is better to take off your jewelry, even if it is 375 standard.

Medical alloy

One of the alloys similar to gold is used in the manufacture of medical instruments; dental crowns were previously made from it. It contains nickel, chromium and magnesium. The products are worn by people with a rare form of allergy to precious metals.

Expert opinion

Vsevolod Kozlovsky

6 years in jewelry making. Knows everything about samples and can identify a fake in 12 seconds

Unlike real gold, medical gold does not react to iodine: this is how you can distinguish a product made from medical gold from the real thing.

Also see how white gold is obtained by combining it with palladium:

Description of the alloy

The most common gold jewelry alloys,

but many people do not know what it is and what elements are included in its composition

.

Their main component is gold, the content of which varies between 75–98%. The following additional components can be used: silver, copper, palladium, platinum. By adding additional metals, you can make an alloy with any shade - from red to light yellow, greenish.

Jewelry alloys are used to make expensive jewelry. They are used to make products with precious stones:

- rings;

- necklace;

- earrings;

- tiaras;

- tie clips;

- cufflinks

Ferrous metals, iron-carbon alloys with additions of chromium and nickel, are not considered jewelry, but they are used to make cheap products that imitate white gold and platinum. Stainless steel and surgical steel began to be used for the manufacture of various accessories with the advent of modern, grunge, and punk styles in youth fashion. The alloy does not darken from moisture and does not cause allergies.