What does a gold sample look like?

The gold standard in Russia has a certain standard. It always looks the same, only the meaning changes.

The gold standard in Russia always contains the image of a girl in a kokoshnik.

K - To the left of the image is a letter of the Russian alphabet. She points to the Assay Supervision Inspectorate where the jewelry was tested.

585 - gold content

Method of applying gold sample

The mechanical method of applying a sample is the most common in the world. Until recently, this was the only option for hallmarking jewelry. It is applied by mechanical deformation of the gold surface using a harder cliche.

The laser method of applying samples began to be used not so long ago. Such a sample can only be found on modern jewelry. It is applied using special equipment, burning a pattern onto the surface of the gold. The piercing depth is not large, so the laser mark may be erased over time.

The electric spark method of applying a sample was a transitional link from mechanical to laser. It differs from laser in its deeper application, which is why it is more durable.

How many samples of gold

Only the state is allowed to test jewelry in Russia. The State Assay Supervision Inspectorate (GIPN) is responsible for this.

In Russia, the metric system is used, it has 6 samples of gold:

- 375

- 500

- 585

- 750

- 958

- 999

Some countries use the karat testing system, where the pure gold content is indicated in karats.

Gold samples

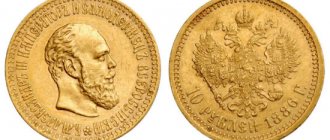

Home / Gold samplesSample is the main indicator of impurities in a product, but stamps also serve this purpose - marks that are placed in control institutions and guarantee the presence of precious metal in the alloy. In France, the first mark was placed in 1275, but in Russia the first mark appeared on a product in Moscow in 1651-1652. It looked like a double-headed eagle with a date written in Slavic letters, and its purpose was to demonstrate the silver standard. Assays in the modern sense were introduced by Peter the Great in his decree of February 13, 1700, which established 4 assays each for gold and silver.

Gold hallmark systems

In the world there are metric, carat and spool systems for gold hallmarks. The most popular are carat and metric, of which the second is most often used. According to the British carat system, which is used in the USA, Switzerland and a number of other countries, a carat is equal to 1/24 of the mass of the entire alloy. Thus, 24 carat gold is a pure substance without additives, but 18 carat means 18 parts of gold in the total proportion of the mixture of metals. In the jewelry industry you can most often find samples: 9, 10, 14, 18 and 24

In Russia, since 1711, a spool sampling system has been in use for silver alloys, and in 1733 it was introduced for gold. This measure was invented on the basis of the Russian pound, which contains 96 spools, and the standard itself was expressed by the weight of gold in 96 alloy units. Pure gold had a 96 hallmark, and at the end of the 19th - early 20th centuries, the 56th, 72nd, 82nd, 92nd and 94th hallmarks were in use.

In 1927, the USSR switched to the metric calculation system; all manufactured products that previously had a spool marking changed it to metric. The new system was identical to the German one, and the sample number ranged from 0 to 1000 and demonstrated the presence of gold in the alloy.

Today, many countries use metric quality standards (the most accurate system). In them, the highest standard is the 1000th, but in fact it is not found, and the mark on gold can be a number up to 999.9.

In connection with the problem of calculation errors in the glory of gold, a so-called remedium is established, in other words, a deviation from the norm. In compounds of silver and gold, gold and copper, and all three components together, the remedium is usually set to 3 units. For example, a 583-carat alloy should have a remedium of 3 units, therefore, the gold content will be approximately 580-586 g/1 kg of alloy. Gold alloys with an admixture of nickel have a remedium of 5 units.

In Russia, jewelry for sale can have hallmarks from 375 to 958. The Union also had gold of the 583rd standard, but in Europe there was a standard of 14 carats, which had indicators higher than the Soviet one. To avoid a lower price for our gold in Europe, the standard was changed to 585.

In the modern Russian system, 23-karat gold corresponds to the 958th hallmark, 18-karat gold to the 750th, and so on. To convert from metric to carat, you need to multiply the sample by 0.024.

Popular gold samples

In our country there are five levels of quality of gold products.

375-I sample is an alloy containing 38 percent metal (impurities - silver and copper), having a color range from yellow to reddish; over time, this mixture fades.

500-i is an alloy with 50.5 percent gold (admixtures are silver and copper).

585-I is a mixture of 58.5 percent gold with silver, copper, palladium and nickel. This combination makes the product hard, durable, and resistant to air, which is why it is often used in production.

750-i is an alloy with a 75.5 percent precious metal content mixed with silver, platinum, copper, nickel and palladium. It can range in color from green and yellow to pink and reddish. Quite durable, but well processed and polished. Very popular for making jewelry, used for high-precision work.

958-i is an alloy with a share of gold of 95.38 percent, which is rarely used due to its softness and inexpressive color.

Alloys higher than 750 standard are not susceptible to tarnishing when interacting with air, and 999 standard is not used due to poor reliability indicators. For works of art, the 958th standard is best suited, the 900th is used for minting, and for jewelry purposes the 585th standard is used.

IN THE RUSSIAN FEDERATION, THE SHARE OF GOLD IN THE ALLOY IS DETERMINED BY THE STATE AND IS INDICATED IN THE RESOLUTION “ON THE PROCEDURE FOR TESTING AND HANDLING OF PRODUCTS FROM PRECIOUS METALS.” PRODUCTS MADE FROM SUCH METALS MUST HAVE THE STAMP OF THE STATE AND COMPLIANCE WITH RUSSIA STANDARDS.

The testing and hallmarking procedure is carried out by the Russian State Assay Office, located under the Ministry of Finance. And compliance with gold hallmarks and their compliance with reality is monitored by specialists from the Federal Assay Supervision.

In Turkey, Egypt, Greece and the USA, gold and silver products are not controlled. In this regard, Russian jewelers say that 90% of Turkish gold does not correspond to the declared quality: often, with the specified 585th standard, it actually barely reached 500th. But recently, trust in Turkish hallmarks has completely disappeared, the fact is that in any store in this country you can choose an unmarked gold product, after which the seller will put the desired number on it using a special machine. Usually, the image of the mark combines a certain design and a digital designation of the sample, and the sample itself, as mentioned earlier, is set by government services.

Prices of different gold samples

Prices are current at the time of writing (June 2021):

| Try | Well | Pawnshop | Shop |

| 375 | 1020 | 950 | 1700-3000 |

| 500 | 1600 | 1300 | 2000-3500 |

| 585 | 1600 | 1500 | 2500-5000 |

| 750 | 2050 | 1900 | 3000-7000 |

| 958 | 2600 | 2500 | — |

| 999 | 2750 | 2600 | — |

You can always independently calculate the price of gold according to the exchange rate on the world market.

The pawnshop accepts gold at a price of 50-100 rubles less than its quotation.

The selling price of gold in a jewelry store is usually 1000 rubles more than the exchange rate.

PROBA-1M automatic sampler

PROBA-1M automatic sampler at OmegaEnergetik LLC. Prices, characteristics, descriptions.

The automatic sampler "PROBA-1M" is designed for taking, according to a given program, samples of commercial oil transported through pipelines with a nominal diameter of 40 to 1200 mm and a pressure of 0.2 to 6.3 MPa.

The automatic sampler "PROBA-1M" is an operational control of the quality of pumped products in commercial oil metering units.

Section: Automatic samplers

Automatic sampler PROBA-1M

designed for sampling, according to a given program, samples of commercial oil transported through pipelines with a nominal diameter from 40 to 1200 mm and pressure from 0.2 to 6.3 MPa. The PROBA-1M sampler is installed at commercial oil metering units for operational control of product quality; sample analysis is carried out in laboratory conditions. sample-1m, sample-1m, sample-1m

PRODUCT COMPOSITION:

— automatic sampler

PROBA-1M

; — sampling probe; — program control unit BPU-A; - balloon.

The sampling probe has designs corresponding to the nominal diameters of the pipeline: 40, 50, 65, 80, 100, 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1200 mm.

Sampler PROBA-1M

has an explosion-proof design, explosion protection marking IExdllBT4.

Automatic sampler PROBA-1M

made in vibration-proof design.

The BPU-A program control unit is designed for installation outside hazardous areas of premises and controls the sampler in the following modes: “volume”, “time”, “manual sampling”.

| Characteristics of the selected product: | |

| Kinematic viscosity, m2/s | (1…120)x10-6 |

| Temperature, °C | +2…+65 |

| Mass fraction of mechanical impurities, %, no more | 0,05 |

| Mass fraction of paraffin, %, no more | 7 |

| Mass fraction of sulfur compounds, %, no more | 3,5 |

| Density, kg/cm3 | 750…990 |

| Maximum vapor pressure at temperature +10…+40 oС, kPa | 29…67 |

| Volume fraction of water, %, no more | 2 |

| Technical characteristics: | |

| Power consumption: | |

| — with the sampler turned on, VA, no more | 320 |

| — with the sampler turned off, VA, no more | 20 |

| Power supply parameters of the Proba-1M sampler: | |

| - type of current - constant | |

| — voltage, V | 140…210 |

| - current, A, no more | 1 |

| — power pulse duration, s | 5 ±0,5 |

| — interval between pulses, s, not less | 20 |

| Power supply parameters of the software BPU-A block: | |

| — voltage, V | 220 |

| - frequency Hz | 50 |

| Sample volume taken by the sampler per cycle, cm3 | 2…20 |

| Sample volume contained in a cylinder, cm3, not less | 3000 |

Overall dimensions and weight of components:

| Name | Overall dimensions, mm | Weight, kg |

| Sampler Proba-1M (without probe) | 240x79x225 | 8,5 |

| Cylinder for sampler Proba-1M | 190x190x220 | 1,5 |

| BPU-A block for Proba-1M sampler | 200x250x155 | 2,1 |

Length and weight of PROBE for automatic sampler PROBA-1M:

| DN, mm | Length | Weight, kg. |

| PROBE-40 sample-1m, sample-1m, sample-1m | 136 | 3,98 |

| ZOND-50 | 143 | 4,12 |

| ZOND-65 | 151 | 4,15 |

| ZOND-80 | 159 | 4,18 |

| ZOND-100 | 168 | 4,21 |

| ZOND-150 | 243 | 4,41 |

| ZOND-200 Mavic, Mavic, Mavic, Mavic | 291 | 4,56 |

| ZOND-250 | 334 | 4,65 |

| ZOND-300 Mavic, Mavic, Mavic | 375 | 4,8 |

| ZOND-350 | 418 | 4,87 |

| ZOND-400 | 456 | 5,3 |

| ZOND-500 | 603 | 7,26 |

| ZOND-600 | 693 | 7,64 |

| ZOND-700 | 772 | 7,83 |

| ZOND-800 | 862 | 8,32 |

| ZOND-1000 | 1042 | 8,44 |

| ZOND-1200 | 1220 | 8,97 |

Marking for ordering the PROBA-1M sampler according to the nominal diameter:

| Name | Nominal pipeline diameter (DN) mm. | Working pressure (PN) MPa |

| Sample-1m-40 | 40 | 6.3 MPa |

| Sample-1m-50 | 50 | 6.3 MPa |

| Sample-1m-65 | 65 | 6.3 MPa |

| Sample-1m-80 | 80 | 6.3 MPa |

| Sample-1m-100 | 100 | 6.3 MPa |

| Sample-1m-150 | 150 | 6.3 MPa |

| Sample-1m-200 | 200 | 6.3 MPa |

| Sample-1m-250 | 250 | 6.3 MPa |

| Sample-1m-300 | 300 | 6.3 MPa |

| Sample-1m-350 | 350 | 6.3 MPa |

| Sample-1m-400 | 400 | 6.3 MPa |

| Sample-1m-500 | 500 | 6.3 MPa |

| Sample-1m-600 | 600 | 6.3 MPa |

| Sample-1m-700 | 700 | 6.3 MPa |

| Sample-1m-800 | 800 | 6.3 MPa |

| Sample-1m-1000 | 1000 | 6.3 MPa |

| Sample-1m-1200 | 1200 | 6.3 MPa |

bugulma bozna, bugulma bozna, bugulma bozna, bugulma bozna sample-1m-40, sample-1m-50, sample-1m-65, sample-1m-80, sample-1m-

100

BPU-A software control unit for automatic samplers |

Sampling PROBE |

VORTEX flow mixer |

Buy with this product

PUSCHT slot-type sampling device |

Tubular type sampling device |

MIG-FB liquid mesh filter |