Hello, dear readers! Today we will plunge into the world of gold mining and examine one of the main methods of extracting this metal. After all, not everyone knows exactly how it is taken out of the ground and separated from other garbage.

The problem is that in addition to nuggets in their pure form, the noble mineral is found in the soil in the form of fine dust. For the purpose of its removal, a device was invented, which will be discussed further - a dredge for extracting gold.

Methods of gold mining in Russia

Gold is considered an expensive, but still not a rare metal. Methods for its extraction from the soil are conventionally divided into mechanical and chemical (when combined with other elements). If we talk about the Russian Federation, the following are recognized as the main ones.

- Amalgamation is based on the special property of mercury to dissolve elements in itself. The rock containing gold is placed in a container with Hg. Over time, these metals combine to form an amalgam, from which the mercury is subsequently evaporated.

- Crystallization using NaCN - this method is very similar to the previous one, only instead of poisonous mercury, the gold-bearing rock is mixed with sodium cyanide, which, when combined with gold, forms yellow crystals.

- The dredge method is the use of a special floating installation (dredge), which collects enriched rock and washes out the precious metal from it.

These are the main methods of industrial gold mining in Russia. In addition to them, manual washing using a sieve is also widespread.

How gold is mined in mines and rivers in Russia, video

There is a theory that gold is located in the molten core of planet Earth - in magma. From there it rises to the surface and becomes available for mining. Experts believe that after the earth's core formed, meteorites fell on the planet and contained small amounts of the precious metal. Thanks to the fall of meteorites, gold fell into the continental crust of the planet, and this ancient meteorite shower was incredibly strong, so much so that it pierced the earth's crust and literally “hid” the precious metal in deep layers.

From these deepest layers, the metal gradually began to emerge to the surface due to high temperatures. Particularly large deposits are located near ancient and long-extinct volcanoes. In those places you can often find large gold bars. Experts believe that this is precisely what the volcanic “exit” of the precious metal to the surface proves. Extracting minerals from the subsoil is an extremely energy-intensive process. There are only two methods of industrial gold mining: open-pit and underground mining.

Open way

People use this method only if the precious metal is very close. This is an excellent way to mine gold from both an environmental and economic point of view. Workers remove rocks from the depths of the earth using explosives and heavy equipment. The equipment delivers all the necessary tools and transports the recovered metal. It is worth noting that all this is very expensive; the price of diesel fuel alone accounts for approximately 30 percent of the cost of gold mining.

In a good open pit mine about one tenth of an ounce of metal will be found in every ton of ore. Based on the cost of an ounce of gold being $900, the cost of ore is $90. Considering that the carrying capacity of the vehicles used in the mines reaches 300 tons or more, a full truck of ore can cost no more than $38. The reality differs from expectations and calculations; during mining, some batches are often richer than others, while some are completely empty.

Closed method

When the gold is very deep, workers resort to underground mining. These are deep mines with a network of tunnels, each of which reaches the deposits. Here it is necessary to drill holes into which explosives are placed, then the rock fragments are pulled out. In rare cases, workers use jackhammers, shovels and carts, but this is a thing of the past; almost no one does this now. In modern mining of precious metals, explosives, powerful rock-loading vehicles, rail vehicles or a huge truck are used. In rare cases, natural conditions allow the use of the most effective self-propelled equipment, then the number of people at this labor-intensive and dangerous stage of production is reduced.

To ensure uninterrupted supply of energy to such mines, wind and solar power plants are sometimes installed nearby; if this is not possible, diesel generators are used. Gold mines are usually very deep, which means ventilation is important. It is also worth paying attention to the transportation of workers and breeds. Without electricity none of this would have happened.

What is a dredge?

Dredges are special machines designed to work with different types of soil. The main functioning element of such installations can be either a multi-bucket in-line mechanism or a suction hose (if the rock is loose). The scooping mechanism is adjusted by a staff of 10 people.

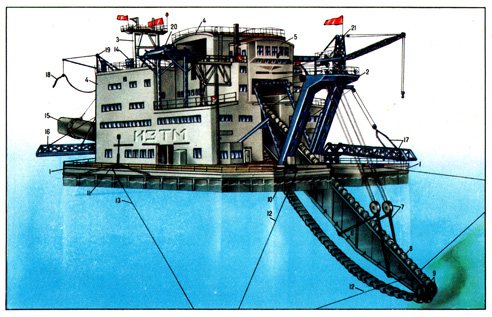

Simply put, this unit acts as an attachment that can be installed on a floating platform or ground transport, and is somewhat reminiscent of a conveyor. Only instead of a tape, movable scooping devices are attached to the frame. They are the ones who scoop out gold-bearing ore from a quarry or from the bottom of seas, oceans, rivers, etc. Subsequently, the extracted conglomerate containing the required element is transported for processing. Below is a photo of the car itself.

Dredge device

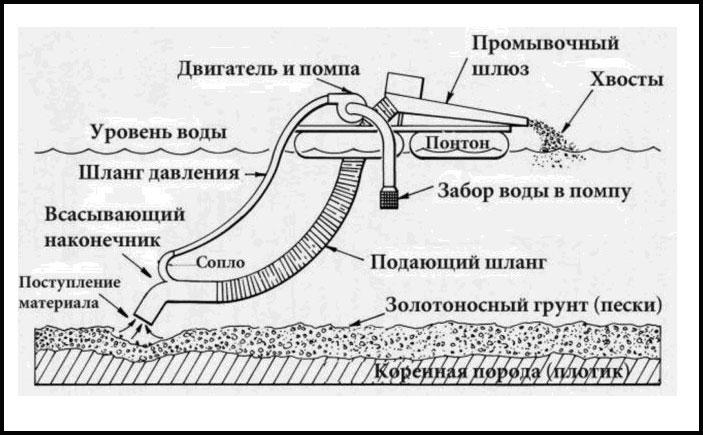

If we talk about a dredge with a bucket working element, then there is nothing complicated in its design. However, there is also a vacuum type of installation, the design of which is different in many respects. It is intended for bulk deposits, which include marine gold-bearing sands. The machine consists of the following mechanisms.

- Pump - creates a suction effect.

- Sleeve - passes rock through itself under the influence of a created vacuum.

- Auxiliary hose - connected to a pump that pumps water, and directs it through a high-pressure pipeline into the hose.

- A sluice is a kind of container that calibrates the rock and throws away large debris.

- Butara - acts as a flushing mechanism.

All these elements work harmoniously, that is, together. Most often they are installed on a floating gold mining platform that operates on water. They are rarely used in quarries.

Dredge

DRAG (from English drag * a. dredge; n. Schwimbagger; f. drague, noria de reprise; i. draga) is a floating mining and processing complex for the development of water-logged mineral deposits (mainly alluvial).

The dredge is equipped with a working body for extracting productive rocks from under water, washing and processing units for enriching them, extracting valuable minerals, and transport and dumping equipment for placing waste rocks (washing tailings) in a dump. The use of dredges for gold mining (single-bucket, lever-bucket type) was first started in 1863 in New Zealand. In 1882 the first two-boom (mechanical shovel type) dredge was built, in 1895 - a multi-bucket electric 150-liter (with an endless chain) dredge. The first dredge with a continuous scoop chain, the possibility of rope-pile maneuvering and a centralized control system (California-type dredge) - the prototype of modern multi-bucket dredges - was produced in 1899 by the American. Dredge construction received its greatest development in the 30s and 40s. 20th century (the operating dredge fleet of capitalist countries included about 400 dredges).

In Russia, the first multi-bucket dredge, converted from a dredge bought in the Netherlands by gold miner P. P. Gudkov, was built in 1893 at the Siberian Rozhdestvensky mine in the valley of the Kudach River. Since 1900, the Nevyansky plant in the Urals began producing domestic dredges (the first, on a wooden pontoon with scoops with a capacity of 113 liters, was called “Pyotr Yakovlev”), since 1903 - the Putilov plant, whose dredges (with scoops of 100 and 150 l) were superior to both domestic and and foreign samples. The pioneer of Soviet dredge construction - (Leningrad) in 1926-30 produced 20 electric dredges with 210 and 380 liter scoops, which made it possible to stop importing this equipment. Drag construction in the USSR received its greatest development in the 2nd half of the 40s. In 1951, the first domestic diamond mining dredges were created, and then dredges for the development of titanium-containing and rare metal placers.

Modern dredges are divided into two classes - continental and sea. They consist of a floating vessel on which massive frame trusses and an above-deck superstructure are rigidly connected to it, as well as front and rear masts, a scooping and shunting device, processing equipment, etc. Continental dredges are designed for the development of continental placers, usually confined to the distribution zone modern or ancient (buried) river systems. These dredges are usually mounted on a flat-bottomed vessel (pontoon). Sea dredges are used to develop alluvial (loose sedimentary) deposits located in the coastal or deep zone of seas and large lakes. They are usually mounted on keel (less often flat-bottomed) self-propelled or towed vessels. Unlike continental dredges, sea dredges do not have a spoiler (stacker) or piles.

Dredges of both classes are equipped with stationary washing and processing equipment (the most common option), mounted directly on the vessel (Fig. 1), or they are operated in conjunction with a separate onshore or floating processing plant. Dredges are also classified according to the type of energy of the drive mechanisms - electric, diesel-electric, diesel and steam; according to the method of movement (maneuvering) in the face - rope, rope-pile, rope-anchor; according to the possible depth of rock excavation below the water level - shallow excavation (up to 6 m), medium excavation depth (up to 15 m), deep excavation (up to 50 m) and ultra-deep excavation; by type of dredging unit - scoopers with a rigid frame (single-bucket shovel type, multi-scoop rotary and articulated-chain with a continuous and intermittent scoop chain), rope scoopers (single-scoop with a grab or dragline bucket, multi-scoop rope-chain), hydraulic and pneumatic suction (dredge) , suction dredgers with mechanical or hydraulic ripper, ejector, airlift, suction dredgers with submersible pumps). Rational scope of application of dredges of various types (according to the maximum depth of excavation of productive rocks below the water level): for multi-bucket rotary and rigid-frame scoops with a continuous and intermittent chain of scoops - 50 m; suction dredgers with mechanical or hydraulic loosening agent - 80 m; airlift (pneumatic suction) - 200 m; grab - 250 m; dragline and multi-bucket rope-chain - 1500 m; ejector (hydraulic suction) and suction dredgers with multi-stage lifting by submersible pumps - 4600 m.

In the early 80s. The most widely used in the USSR and abroad are electric and diesel-electric multi-bucket dredges with a rigid frame and scoops with a capacity of 50-700 liters (Fig. 2), operated on coastal-sea and continental placers of gold, platinum, tin, rare metals and diamonds with depth up to 50 m below water level. Models of domestic dredges: 80D, 150D, 250D, 600D, OM-431, etc. (nominal capacity of scoops 80-600 l). The average hourly productivity of dredges is 100-550 m3.

The development of dredge construction follows the path of maximum unification of dredge units and assemblies, equipping them with efficient controlled electric drive systems and means of automated control, monitoring and remote supervision of technological processes, etc. Dredges used abroad are similar in design to domestic ones.

Operating principle of the dredge

Dredge equipment, regardless of whether it is a pump or a bucket, is designed for one purpose - the extraction of ore containing valuable minerals and its transportation to the destination, that is, to the place where the mined material is either processed or immediately washed (as in the case with gold).

For example, a bucket dredge most often simply dumps the mined conglomerate into a heap, but a floating pumping station immediately washes and collects pure gold, throwing unnecessary debris to the bottom. But the principle is the same - extract, transport and sift.

Heroes of Drag

Sergey Danilov has been the head of the dredge since 1991. I came here as an electrician after technical school and stayed there. Dmitry Sergeevich, the son, followed in his father’s footsteps: he works here as an electrician.

Vladimir Nikitin is the oldest dragger. With only one entry in the work book. He came here as a machinist immediately after the army, in 1978. His first words in response to the offer to go to the drag were: “What is this?” The lack of experience was compensated by the ability to learn quickly. In the first year of its operation, the dredge almost completely burned down.

“We were on our way to a shift in November, and firefighters and police overtook us. We arrive - the dredge is on fire, the shift is on the shore. Fortunately, no one was hurt. According to version, the heater of the workwear became hot and caught fire, says eyewitness Vladimir Nikitin. “Over the winter, the dredge was restored by the mine workers.

Classification

The global specification distinguishes two main types of machines.

- 1st class (quarry dredges) - work in artificially created reservoirs on floating platforms.

- Class 2 (water dredges) - designed for the extraction of bulk rocks from the bottom of seas, lakes, etc.

In addition, dredge installations can be divided depending on their design features and capabilities.

- By type of energy used.

- According to the method of movement.

- Depth of extraction.

- Depending on the type of bucket.

- According to the size of the scoop.

- Method of operation of the bucket chain.

There are quite a few different classifications of installations, but the main one is considered to be the world one, that is, 1st and 2nd classes.

Mini dredge

Another variety is a compact unit that resembles a full-fledged pumping dredge platform. At its core, this is the same installation, only in a smaller version and, accordingly, with limited productivity. It is used mainly by hired miners engaged in legal gold mining.

How to check the flushing unit?

Before mining gold, the equipment should be thoroughly checked. The bottom line is to test the gateway for performance, namely, the capture of small particles of gold from the ore. To do this, take some dense metal, for example, lead, and paint it in a bright color. After this, it is poured into a portion of soil and washed.

Thus, the dredge will catch brightly colored metal no worse than gold. If only 2-3 pieces are lost in the process, then the unit can be considered quite serviceable, and in practice it will perform well.

Is it possible to make a dredge with your own hands?

Based on what was written above, it is theoretically possible to make a mini dredge, but you will have to buy some additional parts. In any case, it will be much cheaper than purchasing a new device (about 3 times). However, it is not a fact that a device assembled by yourself will work well. When designing, you need to take into account many nuances.

Required tools, materials and components

Self-production only involves assembling all the mechanisms into one whole, since it is almost impossible to construct them with your own hands. The list of what you will have to buy consists of the following units.

- Motor - it will turn the main elements.

- Pump - a centrifugal water pump is suitable.

- Compressor - needed to produce air for breathing underwater.

- Pipes are a readily available material.

I would like to draw your attention to the fact that the pump and compressor must be attached to the motor and use its energy to function. Therefore, when purchasing, you need to ensure that their installation is as simple as possible.

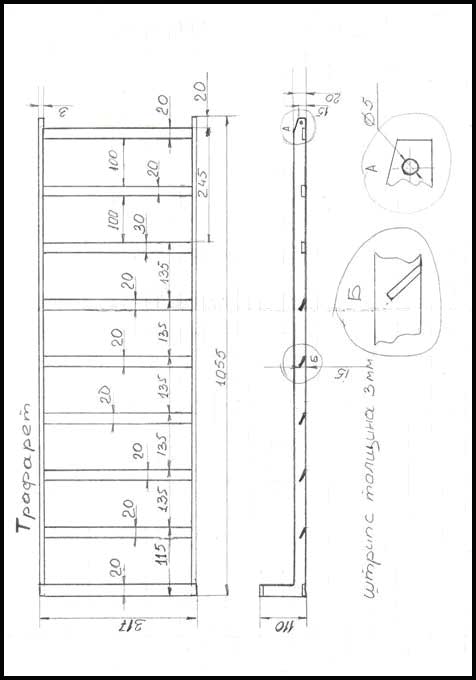

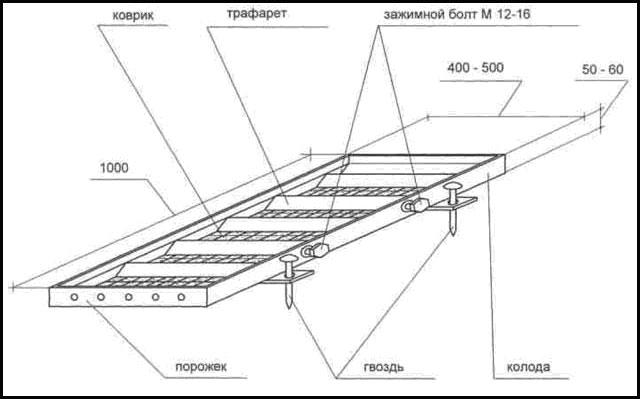

You can also buy a gateway, but it’s quite possible to make it yourself. To do this, you will need aluminum profiles, galvanization and metal of various shapes.

General form

Conventionally, mini dredges are divided into portable and stationary (more productive). The latter are considered more cost-effective because they can operate in deeper bodies of water and are equipped with a compressor to generate air so that the miner can remain under water for a long time. General diagrams and drawings of such installations are presented below.

Gateway drawing

Gateway diagram

General scheme of dredge operation

General view of the installation

In addition to these, there are also so-called hand dredges, which are convenient to work with in shallow water or in streams. The principle of operation is the same, only all the equipment is attached very compactly, which allows you to carry it in your hands. The unit itself is somewhat reminiscent of a vacuum cleaner for gold.

Famous Bottlenose Dolphin 1000

Interesting facts about dredge

- The Votkinsk Heavy Engineering Plant produced steam locomotives, bridges, anti-tank guns, dredgers, and Topol missile systems.

- The dredge was made using American.

- Every year, the Farta Mining Artel contributes 10 million rubles in taxes to the state budget. Insurance premiums amount to 8 million, land rental costs the company another 3.5 million.

- Today in the Sverdlovsk region there are only three dredges, including ours. Two more - on the Neiva River and in the Nizhne-Turinsky district in the village of Is.

- Dredge from the English drague, English. drag "pull, drag, clean the bottom."

- The height of the rear mast is 12.7 meters. Displacement 1446 tons. Weight 1560 tons. The length of the pontoon (this is the basis on which the entire superstructure is built) is 38 meters, width - 22.5 meters. The total area of the current land allotment is 242 hectares.

Work progress

So, you need to start building a dredge for gold mining with a frame for which metal profiles are suitable. It can be of any shape, but it is advisable to make it so that it is easy to install attachments later.

After collection, floating elements (tanks, barrels, hollow pipes) are installed on the created base, which will allow the entire installation to move freely on the surface of the water.

When the main part is ready, you can attach the motor to the frame, and then the pump and compressor to it. Then, accordingly, install pipes - one for collecting water, the second for supplying it under pressure, the third, the most massive, for collecting ore, sand, etc.

The last thing to install is a gateway, which is connected to the main hose, after which the homemade mini dredge is checked. To better understand exactly how it works, you can watch the video.

How to pan or mine gold yourself using a mini dredge?

Before engaging in such a business, you need to know that the mining of precious metals is considered illegal and is punishable in accordance with current legislation. However, this does not stop gold miners, which results in the widespread spread of this fishery in the eastern part of Russia.

You can work with such a device both on land and in reservoirs, but in both cases a water supply is required. In the first, the ore will enter the gateway under the influence of injection, and in the second, it will be done manually, that is, you will have to work with a shovel. There is no particular difference between these methods, and they are both applicable.

How gold was mined in the old days

They started hunting for the precious metal a very long time ago. In the old days, the process was incredibly energy-intensive and risky. The fact is that when mining gold, people were faced with high levels of injury to workers and enormous competition among miners, who, without hesitation, literally destroyed their rivals in the fight for metal. The extraction rate was low, as was the quality of the extracted metal.

Interestingly, gold was most often purified by hand. The method of purifying gold is called “soil washing”. In order to clean the precious metal, people took a tray with a small grid, then took a shovel and put soil in this tray, then washed it all with water. In ancient times, gold miners replaced the tray with the skin of an animal, such as a sheep. Large particles of gold settled on the grate, while the soil was washed off extremely easily at this time. Mostly people tried to find placer deposits. It is worth noting that it is impossible to find a huge amount of gold in this way; at best, you will only find a few grains.