Gold, like silver and the six platinum group metals, is a noble or precious metal.

The first definition (noble metals) reflects the property of gold to be extremely reluctant to combine with non-metallic elements, in particular oxygen. Gold also does not react with most acids. In base metals (copper, iron, etc.), interaction with oxygen causes oxidation - changes in structure and appearance. Gold under normal conditions does not react with any natural substances, and therefore does not change its appearance at all over time.

The second definition (precious metals) refers to the combination of rarity, durability and beauty. This is what allowed gold to remain the most expensive metal from the beginning of human history until the 19th century.

What is gold

Its most common definition is precious or noble metal. But what does this description mean?

Precious ones are rare, durable and eye-catching. And nobility is determined depending on what he reacts with. Gold has an interesting property: it does not react with non-metallic elements, including oxygen, which means that it is not afraid of time or unfavorable conditions.

Physical and chemical properties

Element No. 79 of the periodic table - Aurum - is not hard, but has a high density, and this explains its heavy weight. I suggest you get to know the metal better - I’m sure you didn’t know about many of the properties of gold.

Reflective Features

The metal is distinguished by its property of reflecting infrared and ultraviolet radiation, while transmitting most of the light, therefore gold plating is actively used in the glazing of high-rise buildings, creating visors for astronaut helmets and in instrument making.

Ability to spray

Yes, this noble metal is a master of atomization. And so much so that, according to scientists, the world’s oceans contain about 6,000,000 tons of it!

Flexibility and plasticity

These are two more properties that ensured him the love of jewelers. It can be given any shape, it can be easily compressed and stretched, and it does not need to be broken to bend. To make 100 meters of the finest wire for microcircuits, you need only 1 gram of pure metal.

Ductility

One of the important properties of this metal is malleability. It is possible to form translucent leaves of gold leaf, which have all the qualities of an ordinary precious metal, at almost any temperature, and the thickness of these leaves will be from 1 to 0.1 microns. For comparison: the thickness of a human hair is 80-100 microns. Such sheets are used to cover interior items and church domes. One gram of gold produces a sheet measuring 0.5 m2.

Electrical conductivity

In terms of electrical and thermal conductivity properties, our main character is good. It is a good conductor, but inferior to silver and copper.

Physical properties

Gold belongs to the eleventh group of chemical elements in the periodic table. This is the heaviest metal that man knows about. In nature, only one isotope of a material can be obtained, although a total of 37 are known. This element found its use in ancient times. In different eras of human existence, scientists briefly described the basic properties of gold in different ways. It is the only metal that has a beautiful yellow color and soft shine from the very beginning. The pure material has a warm and bright shade, reminiscent of the sun's rays.

Gold is a fairly dense and durable element. In these parameters it is surpassed only by platinum, iridium and osmium. If you create a cube from the material with an edge one meter long, then its mass will be more than 19 tons. The same iron figure will weigh three times less. Gold begins to melt at a temperature of 1064 degrees, and at a higher level it evaporates. The molten metal has a different shade: it turns from yellow to green.

The pure material is quite soft, making it easy to work with. Its hardness can be increased by using impurities of copper, silver or palladium. Frequent scenes in films and books when characters tried gold coins are not fictional. This is how people determined the authenticity of the metal. Bite marks appeared on real material, but coins with impurities remained undamaged.

Some other properties of gold - plasticity and malleability - allow jewelers to create jewelry, dishes, and figurines from it. Without preheating, the metal can be forged into thin plates. But even in this state it will retain all its properties and color. Due to its ductility, gold is used to make wiring for electronic microcircuits. In addition, the material has low resistance, high oxidation resistance and good thermal conductivity. Precious metal has long been a leader among raw materials for jewelry.

Areas of application of gold

Banking and jewelry are by no means the only industries that use this metal.

Industrial use

Gold is actively used in the electronics industry to create microcircuits for mobile phones and computers. Pliability is the property of metal that makes it suitable for soldering. The thinnest gaskets for ultra-high vacuum are made from gold.

Experts estimate that industrial products already contain 18,000 tons of gold, but consumption of the precious metal by the electronics sector will increase in the near future as the electronic components industry grows in East Asia and China.

Window and stained glass glass is also covered with the thinnest layer of gold, thus protecting the room from heat loss in winter. Among the important properties of gold is the ability to prevent heating by infrared rays.

Spaceships, satellites and astronaut equipment are another area of application for the precious metal. And even in the field of nuclear research, gold is irreplaceable: it is used as a target and a special shell in neutron bombs.

Gold plating saves base metals from damage and gives the appearance of an expensive product; interior designers often use this property.

Medicine and Dentistry

A considerable amount of the world's gold, mixed with other metals, is also used in the medical environment for crowns and dentures. The properties of such alloys protect artificial teeth from corrosion and mechanical damage.

By the way, crowns made of pure gold were found in the mouth of the mummy of Pharaoh Khafre, buried 4,500 years ago. As it turned out, this was practiced not only to demonstrate status and well-being: only such artificial teeth can adhere to the treated enamel so tightly as to almost completely eliminate recurrent caries.

As a nice addition, gold has the ability to protect against unpleasant odors. And, according to some reports, even if you just hold a piece of gold in your mouth, you can cure your throat and nose from colds.

You've probably heard about implanting the finest gold threads under the skin? This is the so-called reinforcement of the face and body. Threads made of pure gold tend to accelerate metabolic processes in the skin, increase its elasticity and straighten wrinkles and folds.

In pharmacology

There is increasingly more information that the precious metal strengthens the body, increases resistance to diseases of the skin and the cardiovascular and nervous systems. The ability to effectively reduce inflammation in joints and have a beneficial effect on hormonal levels is mentioned.

In combination with surgical therapy, radioactive gold is used in the fight against cancer. Its special properties are in demand in drugs designed to combat cancer, tuberculosis, rheumatoid arthritis and dermatological diseases.

By the way, Paracelsus prescribed gold-containing medicines to patients with syphilis.

Eating

In India they believe that regular consumption of special herbs with 1-2 mg of the precious metal rejuvenates the body, and the Japanese add gold foil to tea or sake to improve health.

Since ancient times, many peoples knew about the disinfecting property of golden water and successfully used it for colds, diseases of the liver, bones, lungs and various epidemics.

But modern chefs have gone further: in Istanbul at the Ciragan Palace Kempinski Hotel for $1,000 you can enjoy the “Gold for the Sultan” dessert. However, you need to order it 3 days before visiting the restaurant.

And in one of the best restaurants in New York, for the same price, you can try a dessert that is covered with a sheet of edible gold leaf before serving. Apparently, the demand for sande is not so low, since confectioners did not stop there and created an even greater luxury: an edible jewelry masterpiece worth $25,000. By the way, this dessert was included in the Guinness Book of Records.

Some countries produce candies in edible gold wrappers. To emphasize the high cost and noble origin of some brands of champagne, French manufacturers add gold to their products. This hardly changes the taste properties of the drink.

In England you can buy special confetti made of precious metal, which is poured into a glass of sparkling wine. By the way, here you can also find pies wrapped in almost transparent gold film.

What are the types of gold alloys?

Most often we hear about yellow, white and red gold. But it turns out that the precious metal can come in completely unexpected colors, such as purple and even black.

White

It contains platinum, silver, palladium or nickel. By the way, several years ago the use of the latter in white gold was banned at the legislative level in many countries. This is due to the fact that nickel tends to cause allergies, or more precisely, contact dermatitis in every eighth person.

To obtain such an alloy, you will need 11% platinum or 22% palladium. By the way, manganese also has “whitening” properties. A more budget option contains 10% nickel, 5% zinc and a little copper for ductility.

Yellow

The most common samples of the classic version:

- 585 – contains 58.5% pure gold, 8% silver, 22.5% copper, 8.5% nickel and 2.5% zinc;

- 750 – 5% pure gold and 12.5% each of silver and copper.

Red

This shade of the product indicates that copper predominates as the alloy in the alloy. Its content can be from 25% to 50%. Jewelers can add up to 15% zinc to achieve the desired color.

Pink

This type, in addition to the main component (75%), contains silver (2.75–5%) and copper (20–22.25%).

Other

There are also the following varieties:

- Green: 75% gold, 23% copper, 2% cadmium or 75% gold, 15% silver, 6% copper and 4% cadmium. It should be noted that products made from this alloy look original, but cadmium is considered a toxic metal and has the property of causing serious pathologies.

- Violet or purple: contains 79% gold and 21% aluminum. A distinctive property of such gold is fragility. It is practically impossible to forge, so the parts are simply welded to each other.

- Blue alloy: 46.2% gold and 53.8% indium. As the percentage of aurum increases, the metal tends to lose its blue tint. There is another formula for obtaining blue: 75% gold, 24.4% iron and 0.6% nickel.

Various methods of processing the precious metal can achieve a wide range of colors from black to brown.

Places of origin and production

This material is the oldest among all others. The mining of this precious metal began almost at the same period when the first deposits of copper began to be found, back in Neolithic times. But even despite the fact that gold nuggets began to be mined a very long time ago, today they are found quite rarely. If we turn to historical and statistical data, then over the entire existence of mankind, only 165 thousand tons of this mineral were mined.

If you make one solid cube from all this amount of precious substance, then its side will be about twenty meters. If we make a comparison, the same amount of iron can be extracted in less than an hour.

Today, the largest number of nuggets can be found in the territory of the Republic of South Africa. Also, a large amount of gold reserves are located in China and America. Russia ranks 6th in this rating list. An important reason for this was that America received Alaska, which previously belonged to the Russian Federation. Based on current exchange rates, Alaska was valued at 100 million US dollars. Gold is a precious mineral that is abundant in Alaska. You can learn about this from numerous photo and video reports.

Chukotka and the Amur region are the most significant regions. Where most of the reserves are located. Today, a wide variety of mining methods are used. The main criterion for choosing one method or another is the type of deposits. In order to extract nuggets, a thorough washing method is used. There are places where matter is dispersed. In order to detect and collect it, they use amalgamation.

The largest gold mining sites in the world.

Ores containing this noble material may contain other substances and impurities. In order to extract the purest possible material, it is necessary to carry out a regeneration process or apply cyanidation. There are special factories and production facilities that professionally engage in refining. They use technologies that have a high level of complexity and consist of many stages.

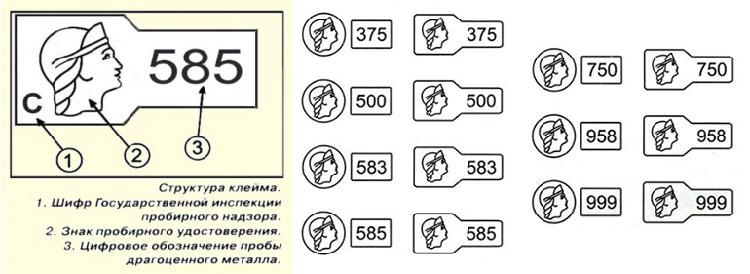

Sample systems

There are 4 gradations of gold samples, the most popular of which are carat and metric.

Zolotnikovaya

The name comes from the word "zolotnik" - an old Russian unit of weight equal to 1/96 of a pound. Thus, 56 samples meant that 96 parts of the alloy contained 56 parts of gold, and the remaining 40 were alloy. For about 2 centuries in Russia, 56, 72, 82, 92 and 94 samples of gold were in use.

Carat

This system came to us from the West. The role of the karat is to indicate the proportion of pure gold in 24 parts of the alloy.

Products come in 24, 18, 14, 12, 10, 9 and 8 carats.

Lotovaya

This gradation is no longer used today; it was used in the Middle Ages in Western Europe. Pure gold was designated in 16 lots; for products with other alloys, samples of 14, 12, 8 and 6 were used.

Metric

System used in most countries of the world. It shows the number of milligrams of precious metal in 1 gram of alloy. For example, in a product of 999 purity, 1 gram contains 999 mg of pure metal and no more than 1 mg of additional components. Noble metal with an admixture of other alloys can have samples: 958, 585, 500 and 375.

This is interesting

With such a variety of samples, some countries have come up with their own designations. Thus, Belgian jewelers stamp their jewelry with the numbers 1 (=833), 2 (=750) or 3 (=585). In Poland the system is different: 1=960, 2=750, 3=585, 4=500, 5=375, 6=333, and in the Czech Republic and Slovakia the samples are as follows: 0=999, 1=986, 2=900, 3 =750, 4=585.

Sample correspondence table

| Metric | Zolotnikovaya | Carat | Lotovaya |

| 999 | 96 | 24 | 16 |

| 958 | 92 | 23 | — |

| 900 | 88 | 22 | 14 |

| 750 | 72 | 18 | 12 |

| 583, 585 | 56 | 14 | — |

| 500 | 48 | 12 | 8 |

| 375 | 36 | 9 | 6 |

Experience using liquid gold

I would like to share my experience of using liquid gold from the German company Heraeus. Gold appears as a dark brown liquid. In my case, the bottle is 10 grams with a gold content of 12%. Designed for painting on glass, ceramics, porcelain. Requires annealing in a muffle furnace. Annealing: The manufacturer indicates the annealing temperature for different types of glass from 480 (soda) to 600 C (borosilicate). I anneal myself at 590 (borosilicate glass). The potter used my gold, but at what temperature he annealed it, I don’t know. Perhaps he annealed it additionally. The manufacturer on its website indicates 780 C for ceramics. However, I don’t know whether it’s the same gold for ceramics or another. If there are knowledgeable people, please share your experience. During annealing, all components except gold burn out. Metallic gold is baked and becomes shiny. As an example, a rim on a glass or porcelain plate. Burning paint has a pungent, suffocating odor. I use delayed annealing by programming the oven to turn on at night. Tips: The paint does not require dilution. Sometimes I dilute it with turpentine to apply it to a large surface area (so that it spreads better). Does not settle (does not require shaking before use). When applied to transparent glass, the paint is difficult to see. I put a sheet of white paper under it. The bottle is not stable. Once I dropped a bottle on the table, spilling most of the gold. After this incident, I inserted a bottle wrapped in paper (so as not to dangle) into a ceramic cup (like a salt shaker). I advise you to apply the paint immediately before placing the product in the oven. (there is always a risk that the product will not survive to annealing; glass chips may stick to the paint, etc.) The manufacturer recommends degreasing the surface. I don't do this because I use borosilicate glass and don't use a thermal blanket. On a new product, there is nowhere for fat to come from. Everything burns in the flame of the burner. I know that when using a thermal blanket, particles of fiberglass included in the composition stick to the products. I think in this case, as well as in the case of painting used products, it is necessary to degrease. The unpainted area can be re-plated with gold and can be partially tinted. I didn’t experience any spots, sagging or transitions. It is useless to try to hide glass defects with gold. The gold will react in this place and there will be no metallic shine. If you don't like how the paint is applied, remove it carefully. I use turpentine and a soft cloth for this. After annealing, poorly removed paint takes on the appearance of a reddish stain and it is no longer possible to remove it. Savings: I recommend not to overfill, but to use a branded bottle. I recommend not washing the brush, but before using it, dip it in turpentine and after a few minutes squeeze the brush onto the neck of the bottle so that the dissolved gold flows inside. Gradually, a coating of dried paint forms on the lid and threaded part of the bottle. I scrape it onto a sheet of paper previously folded in half and pour it along the fold into the bottle. Consumption is very low. But I recommend not to save money by applying a thin layer. The paint has such a consistency that it evens out without leaving brush marks. (like self-leveling floors). If the layer is too thin, it may not be enough for leveling. Can also be translucent. This topic is not an advertisement. Ready to answer any questions. I will be glad to receive your advice.

How is it mined?

There are several methods:

- Ore. Processing gold ore is a rather labor-intensive process. This requires special equipment and permission from the state.

- Manual. The most ancient way. Using a sieve, the gold is filtered in a tray, cleaned of impurities, and then the sand is washed using a special bottle.

- Hydraulic. Potentially gold-bearing rock is eroded by special devices under a certain pressure.

Features of application

The metal-containing preparation is used to decorate tableware, in souvenir production, and when creating unusual paintings. The use of liquid gold is impossible without preliminary preparation:

- the surface on which the design is planned to be applied is cleaned and degreased using a solvent;

- for work you will need a set of several thin brushes;

- the brush is dipped in gold and a painting is created;

- After the process is completed, the painted item dries at room temperature for one hour.

After the liquid gold has solidified, the product is placed in the firing oven for 45–50 minutes.

How to distinguish from a fake

You may have come across recommendations like testing gold on a tooth or scratching a product to see what’s inside. True, one can hardly imagine a seller patiently watching as a potential buyer scrapes a piece of jewelry from a display case with a penknife.

A tip from the same series is to run the product over unfired ceramics. If you managed to escape from the angry seller and saw the golden trail, then it is real.

But I suggest not to risk it and consider other methods.

- First, pay attention to the presence of markings - any product made of precious metals always has a hallmark, and its outlines must be clear.

- Secondly, make sure that the product does not have a “metallic” smell. Real metal also does not have the ability to be attracted by a magnet.

- Next, let's take a closer look at the joints. On jewelry where they are present, you can often see a difference in color; this is one of the signs of a gold product.

There are several other ways to test gold for authenticity, but they are a little extreme and are more suitable if you find the product in your home rather than purchasing it. For example, moisten the jewelry in plain water and draw a line with a lapis pencil. Counterfeit or very low-grade gold tends to leave a mark.

On the Internet, I came across the following advice: rub the product on a thick fabric, such as jeans, and drop iodine on this place. A fake or low grade can be recognized by its ability to darken. But this method seems very doubtful to me, because in this case even the 585 standard is considered low, and brass and copper can just as easily remain indifferent to testing.

By the way, vinegar can also act as a similar indicator - within five minutes spent in this liquid, a product made of another metal will darken. But you wouldn't go to a jewelry store with a bottle of vinegar, would you?

Firing temperature

The air temperature in the kiln ranges between 550–840 degrees Celsius (the choice of temperature depends on the material from which the fired surface is made).

Porcelain cutlery and souvenirs are fired at a temperature of 790–810 degrees Celsius. They stay in the oven for no more than 20 minutes. This time is enough for the pattern to acquire strength and the appropriate color.

Earthenware products are fired at a temperature of 775 degrees. Cutlery made of glass is placed in an oven heated to a temperature of 580 degrees Celsius. The crystal is placed in a furnace heated to no more than 550 degrees Celsius. To fire glass objects, the furnace temperature is not raised above 500 degrees Celsius.

Objects on which a layer of the preparation has been applied are fired separately from things with paints applied to them. Evaporation from organic paints negatively affects the quality of the gold layer. The drawing may warp and wear off over time, which should not be allowed under any circumstances. During firing, special attention is paid to room ventilation. Lack of oxygen after firing can also affect the quality of the product, making the design unclear.

Properly carried out firing allows you to achieve the appearance on the surface of the object subjected to it of a pattern that fully corresponds to the color of real gold. The cost of a product processed in this way increases markedly. But no price can compare with its quality and beauty. Some items turn into real works of art. The demand for them has remained unchanged for many decades.