DIY gold panning table

Rudolf Kavczyk pinned post

How to make a sluice for gold washing with your own hands.

Part 2. Continued.

For a passage/sluice, the gold-catching mat can be made from any natural fabric, such as burlap, tarpaulin, and even a waffle towel, which housewives use in the kitchen. Rugs and fleecy carpets are not convenient to use, since extracting metal from their pile is problematic. The main purpose of the mat is to ensure that the riffles adhere to the bottom of the sluice so that the accumulated material is not washed away by the leaking flow under the riffles. This has been scientifically proven by leading specialists from the IRGIREDMET Institute.

At industrial enterprises, cellular gold-collecting mats are used, or it is also called a stencil. This is due to the technological process of gold mining. The rock is transported to the industrial equipment by multi-ton Belaz trucks, washing thousands of cubic meters of gold-bearing rock per day. Each Belaz truck contains ten grams of gold, which is brought in for washing every few minutes. It is not profitable for the enterprise to stop the washing process to unload the industrial equipment; this will require stopping production for 2-3 hours, and time is gold, in the literal sense of the word. The industrial device is unloaded once a day. Due to the large amount of washed rock, there was a need for cellular mats with a high profile, which accumulate heavy metal and prevent it from being carried away by the flow of water, which increases the time of effective operation of the industrial device.

At its core, a cellular mat works like a stencil/ribbon, only small ones. In the depths of the cells, vortex flows are created that carry away light particles of sand, leaving heavy metals at the bottom: gold, platinum.

You don’t have to use a cellular mat in the passageway, since the rock for washing is not supplied by dump trucks, and gold can be easily removed at any time as heavy material accumulates. In addition, a cellular mining mat is not easy to obtain and its cost of several thousand rubles is not at all justified when used on mini devices.

You can make an analogue of a cellular mat yourself from an ordinary household cellular mat, which many people have on their porch and is sold in every hardware store under the name “anti-slip coating.” The mesh size of the anti-slip coating is approximately 5 mm. See photo.

The anti-slip coating is laid on top of the rag mat. Ribbons are installed on top. Such a system will work no worse than an industrial rug, it’s easier to buy, and its cost is much lower, and if something happens, you won’t mind throwing it away.

Do you need a rug? From the history of gold mining.

“Experiments have been carried out with airlocks where metal stencils were laid on the bottom of the airlock without mats. The experiments gave positive results; no reduction in gold recovery was detected.”

“In Russia in the 30s of the last century, most washing devices used coconut mats as mats. In the 1940s, these expensive imported mats were replaced with similar kalam mats (from the kalam grass growing in Central Asia). A special production facility was organized for their production. The thickness of the mats was 11 mm. To prevent thin gold from being washed away along the bottom of the sluice, which falls right through the mats, mats made of thin dense fabric (calico, canvas, tarpaulin, etc.) were used. After more durable and cheaper rubber mats began to be used in the USA (in the 1930s), their other types gradually fell out of use.”

Sources: “Beneficiation of gold-bearing sands at sluices...”. Author: Doctor of Geological Sciences Zamyatin O.V. -Irkutsk: Irgiredmet Institute, 1998. “Calculation of gold losses during sand enrichment and selection of optimal processing equipment” Authors: Doctor of Geological Sciences O.V. Zamyatin, Candidate of Geological Sciences B.K. Kavchik. — Bull. “Gold mining”: Irkutsk, Institute “Irgiredmet”, 2003, No. 52

In the next chapter: how to properly install a passage in a stream of water. Drawings of the passage. Training video, film on how to make a gateway for gold mining yourself.

Author Rudolf Kavchik, Irkutsk Photo Rudolf Kavchik

Source

Sluice-rumble

Existing hydraulic cradle washing devices, which work on washing sand from small placers and old galle-ephel dumps, have significant drawbacks, consisting in low extraction of gold, especially fine gold. At these direct-flow single-stage sluices, sand classification is not carried out; the sluice operates at high pulp flow rates and the recovery of fine gold is very low.

On

At the Tsipikansky mine of the Zabaikalzoloto plant in 1970, a hydraulic cradle washing device of a new design was constructed, which carries out fine classification of sands directly at the sluice using the own energy of the water flow of the pulp and extracts gold in the sluices of deep and shallow filling, the sub-screening part and in the after-catcher. It has been introduced into production and washes the sands of underground and open-pit mining.

When washing sands with fine gold (class minus 0.5 mm 35%), the recovery is 86.3% on single-stage devices, and 93.8% on a two-stage device, that is, the total recovery is 7.5% higher than on single-stage devices.

The device consists of two parts mounted on a metal sled: a hydraulic cradle and a sluice device. During the rearrangement process, each of these parts is easily transported by a bulldozer to a new instrument stand. Relocation of the entire flushing device, including the pumping unit and extension of the water pipeline, takes from 10 to 20 hours.

The device is supplied with water from a diesel pumping unit, consisting of a 200D-60 pump (8 NDV) and a D-108 diesel engine, mounted on a metal sled, and from a water conduit dia. 300–350 mm. If electricity is available, the diesel engine can be replaced by an electric motor with a power of 75–100 kW, 980 rpm.

Depending on the width of the placer and the thickness of the sand, an area of 3 to 5 thousand m is mined from one device site with a sand transportation distance of no more than 60–80 m.

The most rational place for installing the device is the incision raft. In this case, the washing tailings are stored in the waste space to one of the sides of the placer, and a drainage ditch is supported along the second side of the cut. If it is impossible to install the device on a raft, then it should be installed on the side of the placer (on a peat dump) in such a way that the washing tailings are stored outside the contour of the landfill.

In the parking lot of the flushing device, under the metal sleds (skids) of the hydraulic cradle and the sluice device, beds are laid to facilitate the initial movement of the sluice and hydraulic cradle by a bulldozer when they are rearranged.

After installing the device, the hydraulic cradle on the loading side is sheathed with knurling or sheet iron, a bulldozer is used to create a dump of sand and gravel, and thus a path is created along which the sand is transported by a bulldozer. Sheet iron is welded to the side of the loading hopper, protecting the loading track from being washed away by the jet of the hydraulic monitor.

The hydraulic cradle is a receiving hopper 5 m long and 1.5 m wide. The top of the hopper is covered with a classification grid made of steel, dia. 12–16 mm with 120 mm opening. A hydraulic cradle bath is made under the receiving hopper, into which material with a particle size of minus 120 mm is supplied from the hydraulic cradle tray and directly from the screen.

The 6 m long hydraulic cradle tray is made of three parts: a trapezoidal section, rectangular, ending with a threshold, which prevents possible losses of gold when washed off by a jet of a hydromonitor, and an end tray, from threshold to end, made without a screen, which ensures better discharge of large boulders by jet hydraulic monitor. The hydraulic cradle tray is covered with canopies on top to reduce losses when the pulp is sprayed. In front of the receiving hopper, a GMN-250S hydraulic monitor is installed on consoles, which moves along with the hydraulic cradle. The total length of the gateway is 13.2 m.

1. Deep filling gateway. 5 m long and 0.72 m wide, covered with rubber mats, and on top with ladder-type stencils made of strip steel 70 mm high, 6 mm thick. The width between the thresholds is 110 mm. The pulp flow speed in this area is 2 m/sec. The gateway is covered with a metal mesh on top, locked and sealed.

2. Screening section: the bottom of the deep filling sluice has a drop of 70 mm, over a length of 3.2 m a conical narrowing is made from 720 mm to 650 mm. This section of the sluice is covered with a flat, stationary screen with a hole diameter of 25 mm; here the pulp flow is divided into two layers vertically and the material is screened in the pulp flow; large fractions of the material are transported along the surface of the screen by the water flow to the after-collection sluice.

The under-screen part of the sluice, starting from the head part, is reinforced for 2/3 of the length with rubber mats and seamless stencils. During operation, this part does not silt and gold recovery in this area is 15.5%. The stationary screen gradually narrows towards the tail part, thanks to which the depth of the pulp flow is automatically adjusted, that is, most of the water flow remains under the screen, heading into the deep filling gateway - the additional collection gateway - for transporting large pebbles and catching of gold.

The screen holes are arranged in a checkerboard pattern, with the centers of the holes located at the vertices of equilateral triangles, which gives a high probability of screening the minus fraction from the initial feed.

3. The catcher is a deep filling sluice, its length is 4,250 m, width 650 mm. Reinforced with rubber mats and stair stencils (threshold height 25 mm, distance between thresholds 30 mm, angle of inclination of transverse strips 70%). Over-screening material is transported through this sluice and particles of gold that are not uncovered in lumps of clay are additionally captured. Recovery in this area is 0.9%. Pulp flow speed 2.2 m/sec.

4. The fine filling sluice, which receives the under-sieve product, has a length of 4,250 m.

There is a difference of 70 mm between the bottom of the screen tray and the fine filling sluice.

The airlock is covered with rubber or polyurethane drag carpets produced by Sk-Polymers and seamless metal stencils .

Gold recovery in this area is 2.1%. Pulp flow speed - 1.35 m/sec, filling - 60 mm. Stencils do not flood during operation.

A fine filling sluice, in addition to performing the main technological operation, washing, can serve as a finishing sluice when removing metal.

A gateway with a two-stage extraction scheme is applicable to hydraulic elevator devices.

In this case, the length of the head sluice (deep filling) should be 6 m, the length of the screen - 5 m, the flow distributor - 1.5 m, the shallow filling sluice - 7 m. The total length of the sluice is 19.5 m. Hydraulic cradle-type devices with The two-stage gold extraction scheme can be used on all placers where the sieve composition is characterized by the presence of fine gold.

How to make a sluice for gold washing with your own hands. Part 1.

This article was born in connection with the increased interest in gold mining. I often get asked questions about how to get gold from streams and rivers? How to make a gateway for gold mining with your own hands? Where and what kind of gateway should I buy? How to make a passage with your own hands?

In this article I will tell you how to make a gateway with your own hands. The equipment is so simple that anyone can make it in a couple of hours at home and in many respects it will be better than a purchased American aluminum gateway, the cost of which in Russia reaches 17,000 rubles.

I’ll tell you how to properly make a gold-catching sluice, a mini device for gold mining, popularly called a prodnushka. This is what the prospectors of Siberia and the Urals call it, the name that came to us from our grandfathers and great-grandfathers is prodnushka.

A passage (sluice) is a box made of three boards, at the bottom of which a mat is laid and a stencil (riffle) is placed. A walk-through made of wood is not only simpler and cheaper than one made of aluminum, but most importantly, if something happens, you won’t mind throwing it away. If you use dry and not thick wood, then the weight will be no more than that of an aluminum analogue, and with a skillful approach, even less. In addition, wooden boards in your car or backpack will not raise questions from strangers; no one will ask what kind of boards they are or ask unnecessary questions. You never know what purpose you need these boards for in the forest.

To make a passage (sluice) for gold mining, the main thing is to follow the basic simple rules in its manufacture, and you will be a more successful gold miner than other prospectors with short purchased sluices.

The longer the hole, the more gold you will catch. Foreign aluminum sluices have a maximum length of 1.5 meters; this is not enough to catch fine gold and disintegrate poorly washed sands or loams. The length of foreign locks is 1.5 meters due to legislation that limits the length of the lock, so that amateur tourists do not wash out all the gold on the stream and leave it to others. For example, in America, Australia, and New Zealand, gold mining is a hobby, like picking mushrooms or fishing in our country.

Opportunities for artisanal gold mining

Traditionally, the extraction of the yellow precious metal is divided into industrial and non-industrial. In the case of non-industrial gold mining, we specifically mean artisanal gold mining. This mining method is characterized, in particular, by the fact that it is usually practiced by small groups of gold miners. Large-scale gold mining will never rely on artisanal methods.

Simple ways

Mining gold, at its core, is a simple matter. To do this, you need to take a tray if available, and if you don’t have one, you can use, for example, a plastic basin and a shovel. Using such a simple tool, you can pan several tokens of gold in the river in half a day.

Reference! The icon is a piece of gold that is barely visible to the eye, the size of which varies between 0.07-0.1 mm, and the mass of which is too small to weigh.

In order for gold mining to become a truly profitable business for you, you must have certain knowledge.

It is important to note that all large deposits, as a rule, have already been found and developed.

“Artisanal” gold miners are left with only small deposits that were not included in the list of exploited deposits either during the Soviet Union or after its collapse.

Artisanal gold mining is accessible to everyone

However, today gold miners have the opportunity to extract the yellow precious metal from small placers that were not mined during Soviet times.

As for gold mining itself, it is important to note that before starting to wash the placer, miners search for an area with a significant gold content, the value of which, as a rule, fluctuates within a few grams per ton of rock. To carry out this process, they drill holes along the banks, the depth of which reaches several meters.

We recommend reading: Precious metals market: results of January 2015

If we talk specifically about the method of gold mining, which uses exclusively a washing tray, then it is worth noting that such a tool, as a rule, is a large cup with a rounded bottom and made of wood or metal.

This is interesting! As a rule, gold-bearing sand is rare in nature, so gold miners have to wash a mixture of sand, gravel, pebbles and other rocks in river water.

It is this mixture, which is mined in a pit, that is scooped up with a tray.

Thus, the gold miner’s algorithm of actions may be as follows:

- You need to go to the water and lower the tray there.

- The tray in the water must be rotated with smooth movements to set the rock that is in it in motion.

- As a result of such actions, large stones will move along the edge of the tray and fall out.

- Progressive actions must be performed until all the stones are washed out of the tray.

- Make sure that only concentrate remains in the tray, which is particles of various solid minerals that have a high density.

This concentrate is black in color, due to which gold particles will be clearly visible in it if they were in the washed rock.

With the help of a pass-through

Pass-through for gold mining

Experts note that one of the most professional and profitable methods of artisanal gold mining is gold mining through the use of a tunnel.

Reference! A pass-through is a wooden tray made from several boards.

The passageway is installed directly next to the stream; Water is supplied to it, which usually flows by gravity through a home-made water pipeline. Water is taken a little further upstream.

Gold can be found in almost any body of water

The walk-through must be installed at a slight angle; special ribbed rubber mats should be placed on its bottom, on top of which a sheet of iron should be placed with holes punched in it. It is on this metal sheet that the rock is poured, which must be stirred with a shovel.

We recommend reading: Palladium quotes in July 2015

Such progressive actions allow small fractions to fall into the washing tray, and large stones to “move away” to the side.

Washing allows gold particles to remain on the mats and waste rock to be carried away by water.

After a few hours, you need to carefully remove the mats and then collect the gold from them.

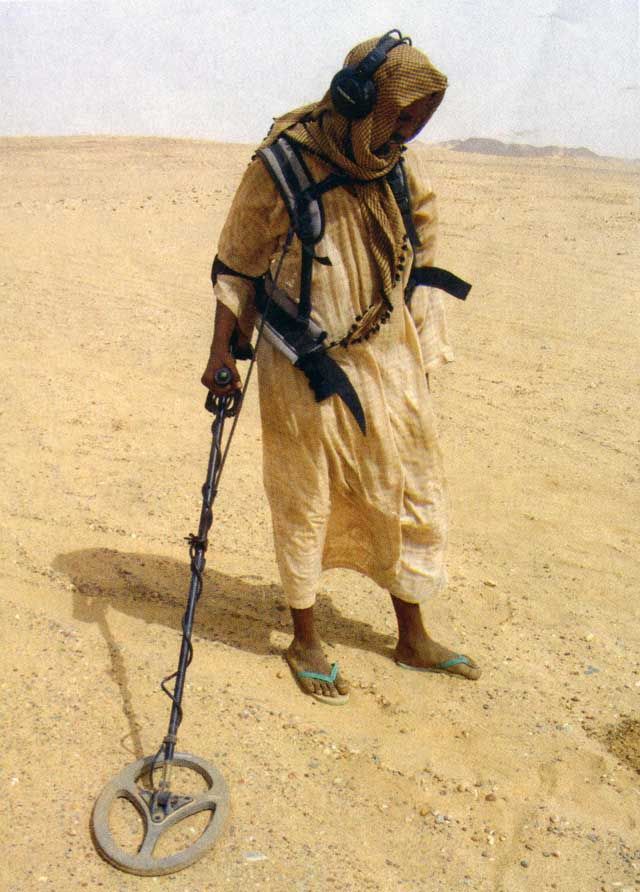

Using a metal detector

Metal detector

At their core, metal detectors are geophysical instruments that are endowed with the ability to influence various metal (or metal-containing) objects that are located in the ground. The operation of metal detectors is based on the electromagnetic principle.

Did you know that all metal detectors, without exception, are equipped with special antennas, which are made in the shape of a ring or an ellipse. It is with the help of such an antenna that the device is endowed with the ability to emit electromagnetic waves that cause special currents in the search metal. Thanks to these currents, the target, that is, the metal, “generates” a response signal to the device, which, in turn, is picked up by the antenna. This signal increases as the distance between the device and the target decreases.

When considering how metal detectors operate, it is important to understand the term “anomaly.”

So, anomalies in the context we are considering should be understood as any changes in the structure of the soil. Since the presence of various metals in the soil is not a normal state for the soil, we consider it (that is, the presence) as an anomaly.

The manifestation of an anomaly when working with metal detectors is accompanied by specific sound vibrations, the appearance of sounds that the metal detector makes.

It is important! An anomaly should be considered an increase in sound only in a certain place.

The problem with searching for gold using a metal detector lies, in particular, in the fact that gold particles are usually small, and, accordingly, when they are detected, the metal detector will not make obvious sounds. Determining that a metal detector has detected gold is often quite difficult.

We recommend reading: 10 countries with the largest gold reserves

Important characteristics of metal detectors that you should pay attention to when choosing and purchasing them include:

- Search depth.

- Sensitivity limit.

- Recognition of metals.

Each of these characteristics must be studied in detail and taken into account when choosing a metal detector.

In addition to metal detectors, other devices for artisanal gold mining have been invented and are being successfully used today. Among them, for example, are automated and (or) mechanized walk-throughs and much more.

Video about artisanal gold mining

In general, there are many methods of artisanal gold mining. We have looked at just a few of them. To summarize the article, we note the methods we considered:

- Mining gold using a simple pan.

- Mining gold using a drill.

- Gold mining using modern equipment (metal detectors, automated and mechanized tunnels, other sophisticated equipment).

These methods can be divided into two groups:

- Methods involving the use of improvised means.

- Methods that require special equipment.

In modern conditions, artisanal gold mining is becoming more and more accessible. However, we should not forget that in the Russian Federation such activities are subject to mandatory special state registration. However, this is a topic for a separate article.

Features of gold mining

Use of gold: areas and possibilities

Nuances of gold mining in Russia

Do-it-yourself gold washing tray: manufacturing rules

Gold mining is often compared to fishing. People have been improving ways of mining solar metal for many years, hoping that they could become richer. Gold panning is considered the most ancient method for extracting the precious metal.

Today, this procedure is carried out using industrial methods, but the washing tray symbolizes miners from all over the world. Using trays you can mine not only gold, but also diamonds and other precious metals.

For on-site testing, a gateway with a width of 25-30 cm and a length of up to 1.5 meters is suitable. It is a rectangular path along which the river current drives sand and silt.

How to make a gold pan?

Many people are interested in how to make their own gold pan. The simplest thing is to buy a plastic basin in a store. But this option is suitable only at first. You will need a spatula for the tray, which is designed to collect the concentrate and analyze it at home comfortably.

Expanded mesh

You can easily make your own washable tray yourself. This will require construction materials. You can easily buy them at the market or in construction stores. To create a frame, a metal tray is suitable.

If this is your first time creating a tray, make a small model so that you can create a full-size version later without making any rookie mistakes.

Materials required to create a wash tray:

- connection in the shape of the letter "T";

- expanded mesh.

The mesh must be fastened to a metal sheet. The T-shaped connection is secured to the area that will stand on the ground.