Hello! Do you know that gold mining is not always a large-scale and complex process that requires special equipment and equipment? You can feel like a gold digger even in your own home; you just need to know the basics of chemistry and get the starting material. Interesting? Then I recommend reading the article to the end, where I will share the secret of how to mine gold at home and how to make this process safe.

What can you get Au from?

Telephones, radio tubes, diodes, computers, microcircuits, connectors—devices containing radio components—are excellent starting materials. The main requirement for them is that these products have a long production period, that is, they must be old. In Soviet times, a large volume of precious metal was used to create radio components; accordingly, the older the device, the more gold can be extracted from it.

Modern devices containing radio components include SIM cards and laptops, although they contain much less precious metal compared to devices from the times of the USSR.

I also use gold-plated items as a source material - cutlery, jewelry, watches. But you shouldn’t expect a large amount of Au in such things: the sputtering on the bodies of such products is applied in a very thin layer, and in order to get a decent amount of gold, you will need to collect more than a dozen pieces of jewelry.

What is gold mined from?

Before moving on to a description of manual mining technologies, let’s consider what can act as a “gold mine” in a populated area. First of all, any gilded objects from the era of socialist realism:

- wristwatches - or rather their cases;

- bijouterie;

- cutlery, not only spoons, forks, knives, but also plates, cups and so on.

One can argue about the design of these products, but for the urban gold miner the main thing is that in the USSR they did not skimp on the use of high-quality materials, including precious metals, in their products!

In addition, electrical appliances, both “ancient” and modern models, or rather their “internals”, are an effective source of raw materials:

- radio components;

- microcircuits;

- connectors;

- transistors and so on.

Fact! The older the device - a PC or TV, the more gold you can mine without leaving your own home and with a minimum amount of equipment designed to remove the precious metal.

Both directions of searching for a “gold mine” are effective. Moreover, the larger the settlement in which the future prospector lives, the higher the chance of collecting a sufficient amount of source material to organize the extraction of yellow metal in large quantities! By the way, nothing prevents you from combining these two directions of search, which will significantly increase the implementation of your goal!

RECOMMENDED: How to make a money amulet

Metal mining methods

There are several ways to obtain AU. Regardless of the chosen method, the raw materials must be prepared before starting work. I sort old and new items into two groups. Then, within each group, I classify devices according to the amount of expensive element it contains. Unnecessary parts in products or old devices are removed to save time and chemicals.

Etching method

The basis of this method is the inability of the precious metal to participate in a chemical reaction with any substances other than aqua regia. Aqua regia is a mixture of hydrochloric acid and nitric acid in a ratio of 1:3.

The method involves making the mixture yourself. The substance has a pungent odor, is initially colorless, but after a short amount of time it becomes light yellow.

I recommend preparing the composition immediately before using it; This way the oxidation function remains at its maximum level.

During the chemical reaction, gold does not oxidize, but remains on the surface of the liquid. He needs to be put down. To do this, you will need to add a reagent to the aqua regia. Hydrogen peroxide, oxalic acid, and sulfite are often used as it, but I recommend using iron sulfate. After adding it, the gold remains on the surface, resembling pieces of foil. I then filter the solution by passing it through a dense material.

Electrolysis mining technology

To mine gold in this way, I will need to fill a glass container with hydrochloric or sulfuric acid, then install 2 iron or lead plates into it. I connect them together with copper wire, then I place a microcircuit there and run an electric current. The microcircuit in this case is the positive electrode.

Under the influence of electric current, a reaction occurs and gold begins to settle on the plates. As soon as the process comes to an end, I turn off the current.

Which way is better

Each method has advantages and disadvantages. Compared to the etching method, the electrolysis method has a more complex technology, but it requires fewer reagents for extraction.

The etching method requires strict adherence to safety precautions, since the likelihood of getting a chemical burn is very high.

These methods are the most effective ways to mine gold at home.

Features of working with reagents

When mining gold on my own, I have to deal with very dangerous substances that have an aggressive effect on human health. For example, nitric oxide released when heated can threaten human life.

I work in a room with very good ventilation. I use rubber gloves, eye protection and a respirator from start to finish. I recommend strictly following safety precautions, then the work will not pose a threat to health.

Andrey and Feodot Popov

The gold rush did not spare our country either. It is believed that the first large reserves of the yellow metal were found in the Tomsk province by the peasant Yegor Lesny. He kept the exact location a secret; all that was known was that the vein was located on the Sukhoi Berikul River. Among those who wanted to find out the secret of the deposit from Lesnoy were the merchant Andrei Popov and his nephew Feodot Popov. However, when the Popovs got to the peasant’s house, he was no longer alive.

This did not stop the prospectors - Andrei Popov applied for the allotment of territory on the Berikul River and, having received permission, together with his nephew opened the “1st Berikul Square” mine. Six years after the start of operation, the mine began to produce so much gold annually that its value was about $300,000. But by that time, the “golden empire” of the Popovs had grown greatly: they owned 120 mines (other merchants owned a total of only 50 mines) in the Salair Ridge, in the Koktekbinsky, Krasnoyarsk and Minusinsk districts of the Yenisei province.

Gold miners in the Yenisei province. (wikimedia.org)

Many historians are inclined to believe that it was the success of Andrei and Theodot Popov that caused the spread of the gold rush in Siberia. New deposits were discovered in the Biryusa, Upper and Lower Tunguska, Pit rivers and their tributaries, and permission to mine gold was issued to 1,125 prospectors. As a result, trade began to develop rapidly in the region and the population grew.

Pros and cons of this business

If we put aside the legality of this process, then I highlight certain advantages:

- production does not require large expenses;

- the process is clear and uncomplicated;

- good payback;

- does not require a lot of time.

However, I also found some disadvantages:

- the reaction is unsafe;

- a large number of things are required to extract, which are not so easy to find;

- Obtaining a license to legalize a business is a rather labor-intensive and time-consuming procedure.

Thomas Walsh

Before becoming the owner of the legendary Camp Bird Mine, which produced more than $20 million worth of precious metals over 20 years, Thomas Walsh managed to move to America from his native Ireland, work in Massachusetts and catch the dreams of miners in Colorado. The turning point in Walsh's life was meeting Smokey Jones in South Carolina. The prospector offered Walsh a share in the Deadwood mine, but he refused, and later regretted it: over time, the site grew into the Homestake mine, one of the richest in North America.

The failure only spurred Walsh on: he firmly decided that next time he would not miss his chance. Hoping to find his own vein, the gold miner went to Colorado and was not mistaken. In the Ouray area, he discovered a deposit that later turned into the Camp-Berd Mine. And 20 years after the opening of the mine, Walsh sold it to a London syndicate and moved with his family to Washington, where they all quickly joined the social life of the city and became quite famous people.

Advertisement for a tour to California, 1850s. (wikimedia.org)

Thomas Walsh is remembered in America not only as a successful entrepreneur, but also as a philanthropist and defender of the rights of the working class. At his mine, people were provided with high wages and a place to live with excellent conditions and excellent food. In addition, Walsh was one of the first to advocate reducing the 10- and 12-hour workday to 8 hours. As a result, Walsh was able to gain surprising loyalty from workers and avoid the strikes that plagued Western mines in the late 1800s and early 1900s.

Tony Beets

Even after 120 years, the story of Yukon gold miners is not over - prospectors continue to search for valuable metal, battling the cruel elements. Among the daredevils who are ready to put everything on the line is Tony Beets. For more than 30 years in business, Tony has become a living legend. In 1984, he and his wife moved to Canada from the Netherlands, where he was engaged in farming and construction. Finding himself in a cult territory for prospectors, Tony immediately got down to business and went in search of gold.

At first, there were more disappointments than successes along his path, but overcoming difficulties only strengthened his character. Over time, Tony's talent as a prospector awakened, and he turned into one of Canada's most successful gold miners.

Jim Skookum, George Carmack and Charlie Dawsen

The last large-scale wave of the gold rush occurred in the Canadian Yukon Territory. It was here that, together with prospectors, the writer Jack London searched for yellow metal, who later described his experience in such works as “White Fang”, “The Call of the Wild” and “A Thousand Dozens”. Gold miners from America, Great Britain, Australia and, of course, Canada itself flocked to the Klondike River.

It all started with three friends: military man George Carmack and the Indians Khaa Kuuh and Kheesh, also known by the names Charlie “Dawsen” Henderson and Skookum Jim. No one can say with certainty who was the first to find gold in the Klondike. According to one version, it was Carmack, according to another, Skookum Jim, who dragged the dead deer to the river. One way or another, they say, a placer of metal lay right at the bottom of Rabbit Creek, and the company did not miss the opportunity to get rich.

Information about the new rich deposit quickly spread around the world and attracted prospectors. Soon the gold reserves in the river became scarce, so finding the precious metal became much more difficult. However, Skookum Jim returned to the Klondike more than once in the summer and continued his search. Carmack also worked in other mines and invested in real estate later in life. During this time, Carmack, Dawsen and Skookum Jim found $1 million worth of gold.

How to make a sluice for gold washing with your own hands. Part 1.

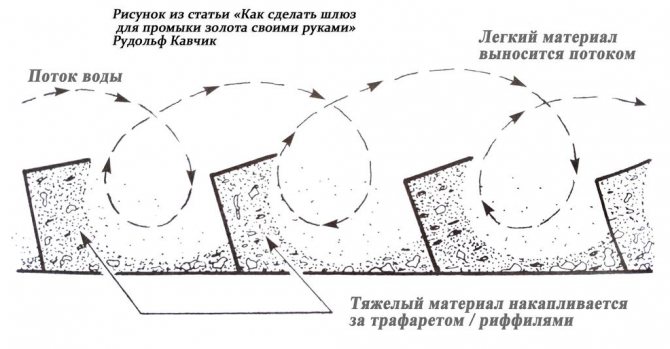

Installation of riffles or as they are also called stencils.

The stencil is the most important part of the pass-through. Behind them, a turbulence of the water flow and its rarefaction occurs. This creates conditions for the accumulation of the heavy fraction behind the riffle plates and the demolition of light unnecessary material. The angle of inclination of the riffle plates depends on the amount of water supplied to the passage and can be from 45 to 78 degrees. The greater the depth of the flow and the speed of the flow of water supplied to the sluice, the greater the angle of inclination of the riffles. The distance between the riffles is 5-7 cm. The shape of the riffles can be straight or with slightly curved edges in the direction of flow.

If the water flow is weak, then riffles are not used. The rock is sifted through a sieve before being fed to the mini device. See the chapter on material screening below.

Gold catching mat.

A gold catching mat can be made from any natural fabric, such as burlap, tarpaulin, and even an ordinary waffle towel that housewives use in the kitchen will do. The main purpose of the mat is to ensure that the riffles adhere to the bottom of the sluice so that the accumulated material is not washed away by the leaking flow under the riffles.

Industrial enterprises use cellular gold-collecting mats. This is due to the technological process of gold mining. The rock is transported to the industrial equipment by multi-ton Belaz trucks, washing thousands of cubic meters of gold-bearing rock per day. Each Belaz truck contains ten grams of gold, which is brought in for washing every few minutes. It is not profitable for the enterprise to stop the washing process to unload the industrial equipment; this will require stopping production for 2-3 hours, and time is gold, in the literal sense of the word. The industrial device is unloaded once a day. Due to the large amount of washed rock, there was a need for cellular mats with a high profile, which accumulate heavy metal and prevent it from being carried away by the flow of water, which increases the time of effective operation of the industrial device.

At its core, a honeycomb mat works like a stencil/reel. In the depths of the cells, vortex flows are created that carry away light particles of sand, leaving heavy metals at the bottom: gold, platinum. You don’t have to use a cellular mat in the passageway, since the rock for washing is not supplied by dump trucks, and gold can be easily removed at any time as heavy material accumulates. In addition, a cellular mining mat is not easy to obtain and its cost of several thousand rubles is not at all justified when used on mini devices.

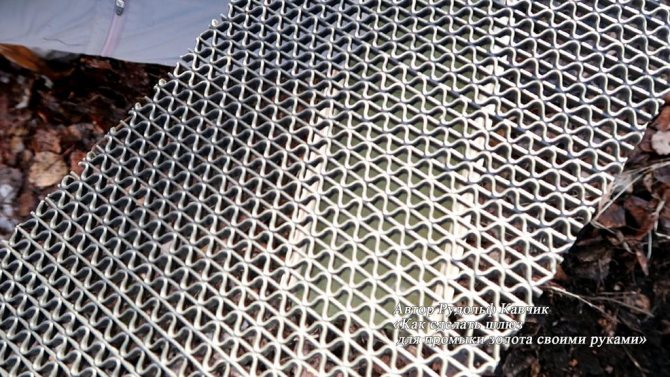

You can make an analogue of a cellular mat yourself from an ordinary household cellular mat, which many people have on their porch and is sold in every hardware store under the name “anti-slip coating.” The mesh size of the anti-slip coating is approximately 5 mm. See photo.

The anti-slip coating is laid on top of the rag mat. Ribbons are installed on top. Such a system will work no worse than an industrial rug, it’s easier to buy, and its cost is much lower, and if something happens, you won’t mind throwing it away.

To be continued... https://vk.com/rudolfkavchik?w=wall24596209_3003

Author Rudolf Kavchik, Irkutsk

Photo by Rudolf Kavczyk

How to make a gateway for gold mining with your own hands. To avoid buying.

Video on how to use the pass-through. Also, you will learn what raft, peat and gold-bearing rock are - sand or layer.

Film directed by Rudolf Kavczyk