Do-it-yourself gold washing tray: 5 recommendations for making

Gold mining is often compared to fishing. People have been improving ways of mining solar metal for many years, hoping that they could become richer. Gold panning is considered the most ancient method for extracting the precious metal.

Today, this procedure is carried out using industrial methods, but the washing tray symbolizes miners from all over the world. Using trays you can mine not only gold, but also diamonds and other precious metals.

People try to make a tray on their own in order to increase the luck that will accompany them in this case, according to legend. In addition to a tray to separate gold grains, you will need a sluice for processes such as gold washing.

For on-site testing, a gateway with a width of 25-30 cm and a length of up to 1.5 meters is suitable. It is a rectangular path along which the river current drives sand and silt.

How to make a gold pan?

Many people are interested in how to make their own gold pan. The simplest thing is to buy a plastic basin in a store. But this option is suitable only at first. You will need a spatula for the tray, which is designed to collect the concentrate and analyze it at home comfortably.

Expanded mesh

You can easily make your own washable tray yourself. This will require construction materials. You can easily buy them at the market or in construction stores. To create a frame, a metal tray is suitable.

If this is your first time creating a tray, make a small model so that you can create a full-size version later without making any rookie mistakes.

Materials required to create a wash tray:

- connection in the shape of the letter "T";

- expanded mesh.

You may be interested in: Where and in what ways is it possible to find gold?

The mesh must be fastened to a metal sheet. The T-shaped connection is secured to the area that will stand on the ground.

If you want, you can reinforce this part with a support sheet of metal. The cost of such a tray is small, and experience in its manufacture will help you learn the process of washing precious metals from the inside.

How to make a washing tray out of wood?

A washable tray made of wood is popular among gold miners. Even a novice miner can make it with his own hands. It is best to choose blanks from dried pine or aspen to produce a glued laminated tray.

When making it, you should follow the following recommendations:

- Prepare two planes and two sides separately. The first and second blanks (bottom) should be cut from a solid log, cutting at an angle of 45%. Using this method, tree rings make the tray more catchable.

- All 4 parts of the washing tray should be carefully planed and fitted to each other. Carefully monitor the accuracy of the sides and their symmetry. They should mirror each other so that the tray has the correct symmetrical shape.

- Glue the first and second planes to the board with glue and screws. Make sure that the joints of both planes are tight and durable. To do this, connect them in a groove with glue.

- The ends of the boards that protrude beyond the end of the side must be cut down, leveled and rounded. An eyelet is drilled on board to attach the tray during camping trips.

- If you find any cracks on the mining tray, they should be covered with a mixture of glue and sawdust. You should not paint the tray, because the paint will remove the wood structure and the catchability will become poor. Also, do not burn the surface, as this will add pits to the surface, which will reduce the quality of the tray. The black color produced by firing can mask concentrates that the miner must quickly detect.

You may be interested in: Where is gold mined in our country?

The finished washing tray will have light weight and high strength, obtained by perpendicular layering of the tray parts to each other. This protects homemade equipment from splits, thereby increasing its quality.

Do not change the shape of the tray. The strict requirement for angles of 140 degrees between planes is characterized by the following: when agitating with a paddle, one side must be horizontal in the water, and the other must be positioned above the water in such a way that rolling into the middle part of the tray is ensured due to gravity and water jets.

If you leave a steeper angle between the planes, this will be disadvantageous due to the dead space formed at the joint. This part of the tray will constantly become clogged with silt. High sides can lead to a similar problem.

Using these recommendations, you can make a washing tray with your own hands. There is a legend that panning for gold from self-made tools will bring good luck to its owner throughout the entire mining period.

Similar articles

vseozolote.ru

Necessary equipment for cleaning gold

To complete such an important task at home, you will need completely simple tools:

- boiled water, in some cases hot; laundry soap or baby shampoo;

- ammonia;

- hydrogen peroxide;

- dishwashing liquid;

- soda;

- sugar;

- bulb;

- potato;

- lipstick from a ladies' cosmetic bag as a paste substitute;

- Toothbrush;

- cotton swabs and disks;

- beer;

- vinegar;

- dentifrice;

- 1 egg;

- soft cloth;

- container for immersing products.

DIY Prospector's Tray.

How to make a gold pan?

The easiest option is to buy a plastic basin at a hardware store. But this is at the initial stage. A real prospector's tray looks like this. What is the spatula in the tray for? To collect concentrate for analysis in the comfort of your home. As you can see, nothing complicated. Smooth plywood. Definitely moisture resistant. The surfaces must be perfectly smooth, then the concentrate can be divided according to the density of the minerals. It is on such a tray that minerals with a density below 3 g per cubic cm can be carefully removed. Next come the minerals of interest. Olivine 3.3 g, diamond has a density of 3.5 g, pyrope 3.8 g, limonite from 3.3 to 4.0 g, almandine 4.3 g, magnetite 5.2 g, copper 8.9 g, etc. to gold having a density of 19.3 g per cubic cm. Only platinum is heavier at 21.4 g per cubic cm. If in a basin it is easy to wash to a gray concentrate, then it is in such a tray that you can finish it to a perfectly black concentrate. Unfortunately, I didn’t think to make a video about how the master works with the tray. We make a tray with our own hands. Dimensions of this tray. Length 53 cm. Width 28 cm. Height 10 cm. Seams must be sealed. And tighten all the parts with self-tapping screws. The length of one half of the bottom is 27 cm. I hope Alexander, a woodworking master, will respond to this publication. I know he has the material available and it is not difficult for him to make such a tray. Alexander, complete the sowing campaign and make a prototype, and also tell us the price at which you are ready to sell the finished tray. www.dilettante55.ru

Types and technology of using trays for gold washing

When and who invented the pan for washing gold, historians find it difficult to answer, but this method of metal extraction has been practiced for thousands of years. Not knowing the laws of physics and chemistry, ancient man learned through practice that gold is heavier than water. Ancient people noticed that gold could be found in river sediments, among rocks, sand and gravel.

Wooden gold pan

Washing river sediments in primitive vessels, people found grains of gold.

Washing gold by hand is a process that requires strength, perseverance, and patience. Many miners complain: you wash a ton of sand, but production is measured in milligrams. Nowadays, many enrichment devices have appeared that make washing easier. And yet, an experienced miner, working tirelessly and vigilantly peering into every washed grain, will wash with a tray much more than the enrichment device.

Devices, despite all their perfection, tend to lose flakes of gold. And the tray allows you to separate gold particles from quartz: wash away the sand and not miss the gold.

Metal mining by tray is possible only in those areas where gold deposits are insignificant. The ability of a wooden tray to catch flake gold is a unique property for the schlich method of searching for placers. Gold flakes are carried by rivers over long distances, and spot mining makes it possible to detect them on river spits.

Today on the Internet you can order trays for washing gold from plastic, metal, wood of various shapes. Americans and Europeans prefer round turbos with a diameter of 16-14 inches. In Siberia, you can order a wooden rectangular tray for four to seven thousand rubles made of aspen, linden, and cedar. Wooden trays from China are sold, which have a good reputation, unlike plastic ones.

But still, prospectors who have considerable experience in gold mining prefer to make trays on their own. Miners are superstitious people and believe in the superstition that only a tool made with their own hands will bring good luck.

Times go by, technology doesn't change

There are two ways to make a wooden tray. The first method is to make a tray from a single piece of wood. The second is made from four parts: two planes and two sides are prepared. All four parts of the tray must fit well together. Particular attention should be paid to the accuracy of the manufacturing of the sides and their symmetry. They must be a mirror image of each other - only in this case the tray will receive a geometrically correct symmetrical shape.

Planes are nailed or screwed to the sides using glue. You should pay attention that the junction of both planes with each other is tight and strong, for which it is best to connect them in the grooves with glue.

The tray of four parts was developed by geologist P. Kharitonov. The layout and drawings of the tray were published in the magazine “Soviet Gold Industry” back in 1935. He also gave advice on how to pan for gold in metal trays. Based on his own experience, he advised prospectors to first acquire a device made of wood, and then, after getting their hands on it, try working with a metal tray.

To this day, according to his drawings, craftsmen make devices for washing gold. Schemes and drawings were reprinted more than once in magazines, and then migrated to the Internet. Kharitonov’s advice is still relevant. Although he called his tray Yakut, similar devices are made from planks in China and South Korea.

Plastic gold washing tray

Many craftsmen prefer to make their instrument in the most ancient way, which was used by our ancestors: to hollow out a tray from a single piece of wood. To do this, a chock 40-60 centimeters long and at least 30 centimeters in diameter is split in two. Wood is removed from the workpiece using a chisel until it is given the correct shape.

A tray made of fresh wood can crack, so it is dried using an accelerated method: with a blowtorch, gas torch, making sure that the tray does not char.

The peculiarity of the tray is that its bottom is cut diagonally towards the layers of wood. At the same time, the wood fibers form roughness at the bottom of the tray, which easily holds gold.

To keep the tray in shape, it is soaked in saline solution for two days. A properly made tray will not dry out or crack over time.

Siberians make trays from cedar, aspen, and pine. It is not recommended to take linden and larch.

The dimensions of the tray may vary and differ from those recommended by the prospector Kharitonov. The classic dimensions of the tray, 30 centimeters wide and 60 centimeters long, are designed for a man of large build: not everyone can wash gold in such a vessel, so you can make a smaller tray.

Some prospectors have two trays: one made of metal and one of wood. In stagnant warm water it is advisable to wash with a metal one, but in a river where there is a current, wash with a wooden one. The wooden tray floats and does not sink. It is much easier to work with it in the river - it is an ideal tool for washing large masses of sand.

We recommend other articles

dedpodaril.com

Industrial devices for searching for precious metals

Industrial devices for gold mining are distinguished according to the following criteria:

- portability,

- productivity,

- by power.

Experienced geologists and prospectors develop devices for gold washing individually for each deposit. To mine gold alone, you can use a portable mining device.

The work proceeds according to the following scheme:

- gold-bearing soil is placed in the receiving compartment, where it is processed and washed with water pressure,

- Once in the drum, the soil is crushed into small pieces,

- grains of 8 mm each fall into the enrichment gateway, the rest is thrown out by the device.

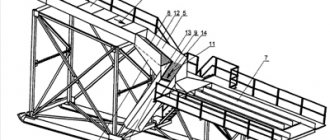

The settings of the industrial device for gold mining allow you to adjust the intensity of soil cleaning depending on its condition and type. The device contains: a gasoline-powered engine and gearbox, drive units, a loading hopper, a drum, pumps, hoses, support wheels, a sluice and a stencil. The last element is the most important detail of the design - grains of gold settle on the removable stencil. To make it more convenient to transport the device from place to place, collapsible installations are made. This is very convenient because the weight of one portable structure can reach 100 kg.

Despite the fact that gold can be found even without the use of special mechanized equipment, you should not do this without special permission from the state. It is important to remember that illegal mining of the yellow metal can imprison you for up to 7 years, with confiscation of gold.

Applications and manufacturing methods of gold washing tray

A gold pan is a tool that is used during prospecting for precious metals. The fact is that this method is the most ancient, but is still used in work. Finding gold is no easy task, but panning can remove all the unwanted soil particles, leaving behind the precious metal. It has been proven that modern machines are capable of fixing a gold particle measuring 0.25 mm, which a tray cannot do. But a gold pan is a cheaper and also effective method of primary purification.

Benefits of using trays

For professional gold miners, washing gold in a tray turns into a separate ritual. Because this skill comes with age and turns into the art of looking at the gold pieces at the bottom of the tray and not losing sight of them. But ordinary local historians should also have the ability to operate a tray, since in this way you can quickly check on the ground whether there is gold in the soil.

Plastic Gold Washing Tray

All gold washing trays are divided into two types:

- specialized models;

- kitchen utensils and other things that resemble a tray.

Of course, a specialized device has its advantages. First of all, this is high labor productivity when using it, the ability to wash large volumes and not allow gold particles to pass through, and prevent unnecessary turbulence in the water. But kitchen utensils, for example, an Asian ladle, which is often used for washing purposes, have disadvantages:

- the volume of sand washed at one time does not exceed two kilograms;

- the stream of water flowing out of the bucket is uneven, so it’s difficult to keep track of all the particles;

- there is no way to use a rake, so you have to rub sand or clay particles with your fingers;

- A lot of gold particles flow out over the side during washing.

Therefore, for proper washing it is better to use specially shaped trays. Then the amount of gold mined will increase several times. Such trays are made from sheets of iron or plank. They differ not only in material, but also in purpose of use.

For example, wooden trays are more suitable for initial rough washing. This depends on the fact that the walls of the wooden tray are rougher, and due to defects and chips in the walls, you may not notice a small particle of the precious metal. Any unevenness in the manufacture of the tray will lead to the fact that over time they will become clogged with empty material. The iron tray does not have such a pronounced relief, so it is easier to work with. Iron trays are heavier, but professionals often choose them.

How to make a tray with your own hands?

Making an iron tray at home is difficult. At the initial stages, you can build a wooden device with your own hands. The operating principles for making a wooden tray yourself are as follows:

- Symmetrical parts (there must be at least four of them). Two parts are used for the base of the tray, and two for the sides. The shape of the tray should not be round.

- The protruding ends of the boards should be smoothed or sawed off.

- Much attention will have to be paid to grinding, since the amount of washed gold depends on the smooth surface.

- You need to connect the boards using screws or, better yet, grooves and glue in order to bring the parts of the tray as close as possible to each other.

V-shaped tray for washing gold

If you decide to make your tray from iron, select the thickness of the sheet - it should not be less than 0.8 millimeters. After this, draw out the shape of the tray and use scissors to cut out the contours, simultaneously bending the ends of the tray along the drawn lines. Do not forget that the tray is not carried in the hands, so both the iron and wooden versions require a rope to secure the tray to clothing. But the size of the instance does not matter. Choose a tray that is comfortable to carry and can also be used with a large amount of sand.

Washing with a tray includes steps such as: placing the tray in water, wiping with a comb, depositing gold, and washing away light particles. After this, they get rid of the ephels and wash the concentrates and precious metal into the bowl.

The process is quite interesting and requires certain skills. At the same time, washing is the dirtiest stage and involves hard physical labor. Even a beginner in gold mining can try his hand at this and get a few pieces of gold with his own hands.

hochuzoloto.com