What it is

It is impossible to find a pure element in nature: in any case, it contains impurities. To make jewelry, it must be cleaned, but the share of pure metal in the finished product does not exceed 75%.

Gold that has been purified from impurities is used only for investment purposes. It is also used as sputtering in electronics. And in common people it is also called “technical”. It is not suitable for making jewelry, but is widely used in other fields.

How to extract gold using aqua regia?

The extraction of gold is associated with certain difficulties, the main of which is considered to be the inertness of the precious metal. Au does not react with most acids and alkalis, which successfully dissolve other metals. But there are substances in nature that can dissolve not only gold, but also platinum, one of these is the so-called aqua regia.

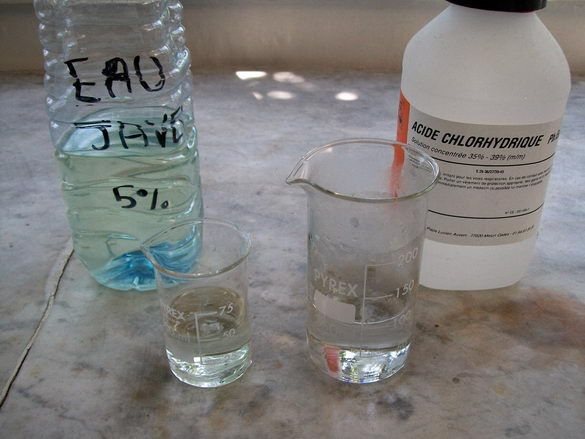

To obtain a solvent, which has been known to mankind since the times of alchemy, you need to prepare a mixture of two acids. Concentrated nitric and hydrochloric acids are mixed in a ratio of 1:3. The mixture of two acids has an orange tint and has a pronounced chlorine smell.

When extracting gold from radio components and microcircuit parts, you should not prepare the solution in advance: the longer it sits, the weaker it becomes.

It is advisable to prepare the mixture in a pan or dish made of aluminum; this metal does not dissolve in a mixture of two acids, for this reason it is preferred. But before you start mixing the reagents, you need to make sure that there is no damage on the surface of the pan or dishes: scratches, chips, cracks, etc.

Preparation of the solution will take some time; the reagents are mixed gradually, stirring them with a glass stick. When the acid mixture is ready, all parts containing Au must be immersed in it.

It will take a long time to extract gold; the average duration of the procedure is about six hours. To speed up the process, you can heat the solution to a temperature of 60–70 degrees. This will be enough for the reaction to go faster.

But during the refining process, the mixture of two acids releases gas, the fumes are so toxic that one breath will be enough to make you lose consciousness. For this reason, when working with acid, it is recommended to use special protective equipment, as well as ventilate the room. Opening a window, balcony or window will help reduce the concentration of harmful fumes in the room and provide fresh air.

The metals from which the parts are made will quickly dissolve in a mixture of two acids, but the gold will settle to the bottom. The sediment will have a characteristic dark tint. To extract Au from a solution, simply filter it. After filtration, a person will have a certain amount of metal on their hands, but it will contain impurities. Repeated refining will help remove them: to get high-quality gold, you need to repeat the procedure 3-4 times.

Gold precipitation

To turn the precipitate into metal, you need to add hydrazine to the solution; this white powder is considered harmless. Hydrazine is added in proportions of 1:5. After adding, you can see how a dark-colored mass begins to peel off - this is gold, only with a large number of impurities.

After the precious metal has been in a mixture of two acids several times, it must be dried and melted into an ingot.

There is one more nuance that should be taken into account when carrying out the procedure. If the solution is heated, it will begin to bubble. The amount of liquid in the pan will increase, so you need to choose a spacious container in which the parts will touch each other, but will be completely covered with the solution.

Etching is a labor-intensive and quite exciting procedure; it helps to extract gold from equipment parts and microcircuits. A mixture of two acids is also used to obtain platinum, but silver is not extracted in this way.

The fact is that this metal does not dissolve well in aqua regia. A film (silver chloride) forms on the surface of the silver; it is this film that prevents the metal from decomposing into molecules.

You can carry out the procedure in the laboratory if you have reagents, but if you have some knowledge of chemistry, then it won’t be too difficult to do everything at home. But you should carefully monitor the condition of the reagents, since if their quality is low, it is unlikely that it will be possible to extract gold from microcircuit parts.

But etching is not the only way to get a piece of yellow metal without leaving home.

Areas of application

I have already said that such an alloy is used in various fields:

- Most of this metal is used in electronics. After processing, the gold ends up in radio components.

- In dentistry it is used for the manufacture of dentures.

- Cancer and tuberculosis are treated with the help of individual isotopes of gold.

- Component of some medications.

- Some parts in the aviation industry can only be plated with gold.

- Gilding metals protects them from corrosion.

We extract gold from motherboards (17 photos)

| Today you will learn how you can get gold from old motherboards with your own hands. Please note: the chemicals used in the demonstration are very dangerous, especially in the concentrations used. Therefore, we do not recommend repeating this experiment at home. |

All these connectors are often coated with a thin layer of gold several microns thick. Tools

The first stage of our experiment is to remove all these contacts and connectors. We will need wire cutters, pliers and a cutter, a flathead and Phillips screwdriver, as well as some time.

To carry out experiments, you need a large number of contacts - our “donor” motherboards provided them.

Chemical reagents and tools are also needed.

Electrolysis

To get a few micrograms of gold deposited on the contacts, we need an electrolytic cell. 95% concentrated sulfuric acid is poured into the bath. The cathode is made of lead, the anode is made of copper. The contacts (raw materials) are connected to the anode, which we made in the shape of a basket.

When we run electric current through the cell (we used a regular battery charger), the copper on the anode (and on the contacts) dissolves and deposits on the lead cathode. The gold, no longer bound to the copper, forms a sediment at the bottom of the cell. It should also be noted that during this process the temperature in the bath increases significantly.

After the gold has been separated from the contacts, the bath must be allowed to settle.

You should then remove as much of the sulfuric acid as possible, after which you can begin to dissolve the residue at the bottom of the electrolytic cell. Dilution

Be careful and always pour the acid into the water, and not the other way around! If you make a mistake, the first drops of water that come into contact with the sulfuric acid will instantly evaporate, and the acid may splash out.

We have a solution of sulfuric acid, various metals (including gold) and waste that needs to be filtered.

Why not filter the acid directly, without diluting it? Simply because paper filters cannot withstand concentrated sulfuric acid. Dissolution

A mixture of different metals and waste will remain in the filter. Now we will dissolve all this in a mixture of 35% hydrochloric acid and 5% chlorine bleach (sodium hypochlorite), in a 2:1 ratio. 2 HCl + NaClO -> Cl2 + NaCl + H2O

Be careful! This reaction is exothermic and releases chlorine, a very dangerous gas. Chlorine was used as a chemical weapon in the First World War.

In fact, we will use the chlorine that was released as a result of mixing hydrochloric acid and chlorine bleach to dissolve gold in the form of gold chloride III.2 Au + 3 Cl2 -> 2 AuCl3

Filtration again

Now we need to filter again.

The filter will retain all waste, leaving only the gold chloride solution III. Precipitation

To obtain metallic gold, we need to precipitate it in solution. For this purpose we will use powdered sodium metabisulfite. In the presence of water, sodium metabisulfite gives sodium bisulfite. Na2S2O2 + H2O -> 2 NaHSO3 It is sodium bisulfite that will allow us to precipitate gold. 3 NaHSO3 + 2 AuCl3 + 3 H2O -> 3 NaHSO4 + 6 HCl + 2 Au

We need to let the solution settle, after which we will get a gray powder at the bottom of the beaker.

Don't lose a single grain - it's metallic gold! Melting

Now we need to melt the powder in a crucible. The melting point of gold is 1064°C, so we will need an oxy-butane torch.

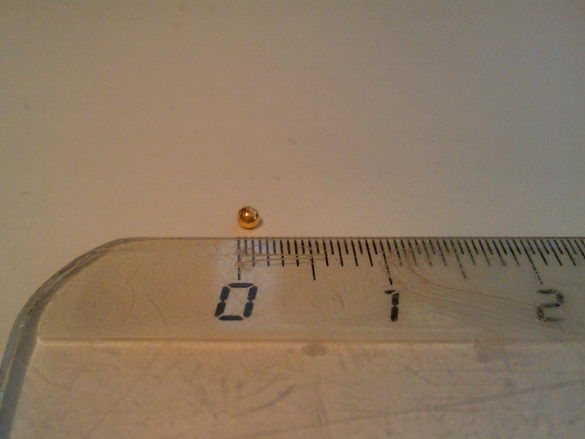

As a result, we got a nice golden pellet! Can our process be called economically justified? Definitely not. It only makes sense on an industrial scale. The small gold pellet we received is worth only two or three dollars at today's prices. And, frankly, the companies that extract gold from old computers use other technologies and chemicals that are even more dangerous. But, you see, it’s still interesting to know that you can get gold from your motherboard at home. You can also get gold from expansion cards, processors and chipsets.

How is it mined?

10% of all gold mining is used in industrial devices. It turns out that the metal can be extracted from there. This process is called refining. It includes cleaning the alloy from all impurities.

What technology is there?

As I said, the gold is in the technical details. A mobile phone, laptop, printer, scanner and other common devices are a source of small amounts of precious metal.

Costs of separating gold from radio components

In production, when using special equipment, they justify themselves, although refining is not an easy process. Some craftsmen are trying to mine gold at home. In this case, you need to make sure that the end result covers the costs, because you will have to purchase a lot:

- dishes for melting;

- stirring stick;

- funnel;

- high temperature stove;

- porcelain containers;

- various reagents;

- protective equipment (gloves, etc.).

Extraction technique and purification of impurities

Refining is carried out in different ways:

- Chemical. Its essence is the dissolution of metal in aqua regia. Before carrying out work, find out the amount of silver, if it is one of the impurities, since silver will not dissolve. Aqua regia is prepared from nitric and hydrochloric acids. The solution must be used immediately, otherwise it will lose its properties.

- Dry. Tin chloride is used. It must be mixed with hydrochloric acid and water. Once the reaction is complete, the gold can be melted down.

- Electrolysis. It will require a 999 sample. It will be the anode, and gold will settle on the cathode. You also need a bath filled with a solution of gold chloride and hydrochloric acid, where electrolysis will take place.

There is an interesting technique for obtaining technical gold from radio components:

- Use a magnet to remove gold-plated steel.

- Immerse the part in a solution of hydrochloric acid and peroxide for a week.

- The exfoliated flakes are washed using a filter and fused.

Next, watch an interesting video:

What is refining and how to carry it out?

Refining is a method of extracting precious metal from parts. Microcircuits and other parts of devices are not made of pure gold, because in this case the price of equipment would be truly astronomical. Gold plating is applied to individual parts of the board - sputtering helps achieve the desired result and save costs. For this reason, the presence of Au in the device does not have a special impact on the cost of electronics.

So, having collected all the parts that may contain precious metal, it is necessary to prepare them for the evaporation procedure.

To begin with, the parts are sorted and laid out by size, then solder residues or other elements are removed from their surface, checked with a magnet and sorted into several piles. Those parts of the microcircuits that react to the magnet are placed in one direction, and those that do not give such a reaction are placed in the other.

Sorting will help minimize the cost of reagents and speed up the process of obtaining gold from radio components.

Gold refining

Refining (evaporation) is a procedure that can be carried out at home if you have some reagents and the skill to work with them. In order to separate gold from other metals, you need a solvent. Au is inert, the element does not react with acids and alkalis, but there is an exception to the rule - aqua regia is considered this exception.

Aqua regia is a universal solvent and an integral part of refining. It is a mixture of two acids, which chemists call by this name. To obtain a solvent, you need to mix hydrochloric and nitric acid in a ratio of 1 to 3.

The mixture will have a clear color and a strong odor of chlorine and nitrogen. Over time, the color of the solvent will change - it will acquire an orange tint. You cannot store aqua regia: the longer the mixture sits idle, the faster it loses its properties.

Gold comes into contact with a mixture of acids and begins to dissolve, a process that occurs more slowly compared to other metals. By immersing the parts in a flask or dish, you will notice how gold flakes appear on the surface of the solution. If the flask is heated, the reaction will go faster. Some Au will remain in solution.

When flakes appear on the surface of the solution, action must be taken immediately. To extract gold from aqua regia, pass the solution through a thick cloth. Filtration will help separate Au from other elements. The fabric should be so dense that even small grains of precious metal remain on its surface.

The resulting gold is then washed with water as the dissolution reaction continues. Then it is worth melting the resulting material by heating it in a burner.

Refining is a fascinating procedure, but it has its own nuances; if evaporation is carried out for the first time, then you need to additionally familiarize yourself with information on this topic. The reaction may not take place due to poor quality of the reagents or inept actions of an inexperienced chemist.

At the end of all the actions, there is a chance to hold a piece of gold or a small ingot in your hands. The quality of the metal will depend on human actions. Some people were able to obtain white gold at home using reagents - an alloy of nickel and Au, which may contain platinum.

During the evaporation process you can get gold:

- Of red color.

- Green tint.

In addition to the usual yellow color, you can get Au in an unusual shade. The color of the metal changes due to the presence of other elements in the alloy, which give the gold an unusual color.

Where can you buy and sell

If you go to a regular pawnshop, nothing will work. There are special points for the purchase and processing of technical gold. Each facility must have a license to operate.

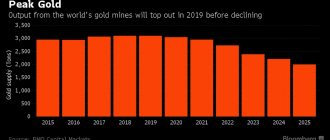

Price per 1 gram

The price varies from organization to organization and depends on:

- amount of metal mined;

- demand for it;

- exchange rates;

- distribution of the country's gold reserves.

Below is the price for today for Russia according to the Central Bank.

But if you managed to isolate technical gold, then you won’t be able to sell it except at the “scrap” price.

| Price 999 standard according to the Central Bank | Market value of the sample today | Scrap price | Price in jewelry |

Gold in the computer processor

The processor is the main device of the computer, performing all its main (computing) work. It is also worth highlighting as a component containing precious metals.

Consider the gold content in grams in 1 kg of processors

Cyrix Cx486 — 5.17 grams IBM 5×86C — 4.8 grams 486 DX2-80 — 4.3 grams i 486 SX — 4.2 grams i 486 TX486DLC — 6.72 grams AMD — 6.15 grams Cyrix 6×86 — 4.83 grams IBM 6×86MX PR200 — 5 .75 grams Cyrix MII— 4.32 grams Intel Pentium — 8.00 grams Pentium PRO — 11.40 grams WinChip C6-PSME200GA — 5.80 grams Intel i435 DX4 — 8.50 grams Intel i486 — 8.60 grams i processor — 6.80 grams Intel Pentium MMX — 4.00 grams AMD-K6-2 — 5.00 grams AMD (brown case)— 7.90 grams

FAQ

Is it worth mining gold at home?

You need to be as careful as possible both when carrying out refining and when trying to sell the resulting metal. Please note that the organization must have a license! You can try to mine gold for fun and keep the result of the experience at home as a trophy.

Is it profitable to obtain precious metals from parts?

If your costs are compensated, then there is definitely a benefit. But think about how much you need to buy. How much time will you spend? Does the end always justify the means?

Is it possible to make jewelry from technical gold?

This is prohibited in our country. Check products carefully before purchasing. There must be a sample on them!

Gold in industry and technology

It won’t surprise anyone that jewelry and accessories are made from precious metal, but few people know that microcircuits also contain gold. In fact, metal is added to parts due to its inertness to speed up the transmission of electric current. Sputtering is applied to contacts or individual parts of the microcircuit, as a result of which the equipment works faster.

Gold in the motherboard

A good example of modern equipment that contains precious metals is:

- Smartphones and other gadgets.

- Tablets and laptops.

- Computers, TVs and refrigerators.

There is gold in mobile phones and even SIM cards. But the precious metal content in SIM cards is negligible.

By disassembling the equipment, you can find parts of the corresponding color; they can contain from 1 to 7 grams of gold. But you shouldn’t focus only on color; some manufacturers cover gold with a layer of copper or dilute Au with platinum. Parts can be not only yellow, white, but even red.

It is difficult to visually recognize which devices contain precious metal and which do not. For this reason, before disassembling the equipment, you need to have an idea of which parts contain gold and which parts you shouldn’t look for.

In what parts can you look for noble metal:

- Radio tubes - gold is applied to a grid, which is located in close proximity to the cathode. The coating protects the grid from electron generation.

- In transistors, the precious metal can be found under the conductors and crystals.

- Military type capacitors - their metal content can be up to 7 grams.

- Resistors - the element is contained in diodes, semiconductors, stabilizers.

- Connectors - if we are talking about old electronics, then a large number of connectors of such equipment are covered with a layer of gold.

- Microcircuits - Au can be found in leads that have a characteristic color and are sealed in glass or ceramic cases. The weight of gold is 10% of the weight of the entire part.

It is difficult to determine the gold content in devices “by eye”; the passport that the equipment has will help you figure it out.

The noble metal can be found in motherboards and processors. But before you begin to analyze the equipment, you need to make sure that gold is still present in this or that device.

Gold utensils can be found throughout the home. Old-style computers are especially rich in elements. But the presence of parts and equipment that contains Au does not guarantee success during refining. This procedure will help separate the gold from other metals and turn it into a small ingot.

If we talk in more detail about the industrial scale of gold use, we can note that the metal is used in the automotive industry, medicine and other industries. The element is part of the instruments used by doctors. The higher the percentage of Au in a tool, the higher its quality and price. An element of noble origin can also be found in hearing aids and implants.

USSR TVs

This gadget was previously released in two versions : a tube device and a transistor device.

It makes no sense to buy tube TVs, since precious metals are contained in these devices only in the beam tetrode - the largest lamp marked 6P36S, 6P44S, 6P45S, GU50.

Another thing is transistor TVs. There is an abundance of precious metals here.

Buyers are interested in the following elements :

- microcircuits encased in plastic housings;

- transistors marked KT814, KT940, KT310, KT502, KT503;

- AL307 LEDs in the channel switching unit;

- “yellow” (according to the color of the case) transistors KT203, located in the SMRK unit and in some variants (models) on other boards;

- capacitors KM-1;

- “yellow”, sometimes “red” capacitors K10-17, etc.

Any product is subject to careful inspection, since products of this type, produced in the Union, were distinguished by a variety of models .

In addition, one device could have different configurations, both containing precious metals and not using them.

We bring to your attention a table that shows which USSR TVs contain valuable elements and how many there are. The mass of precious metals in one product is given in grams.

| Model | Au (gold) | Ag (silver) | Pt (platinum) | Pd (palladium) |

| Knight | 0,3412 | 7,4606 | 0,622 | 0,3199 |

| Horizon-Ts355 (Ts355D) | 0,6785 | 3,7443 | 0,43 | 0,318 |

| Rainbow-719-1 | 0,3135 | 7,1795 | 0,6294 | 0,0339 |

| Rubin Ts202 (Ts208) | 0,4443 | 3,6787 | 0 | 0 |

| Electron-736 | 0,24 | 6,33 | 0,225 | 0,0338 |

If we compare the content of precious metals in Soviet TVs “Horizon”, “Vityaz”, etc. with imported ones, it is worth noting that a device manufactured in Japanese and Chinese, Taiwanese or Korean assembly contains only 0.1474 g of gold and 2.4859 g of silver.