What gold looks like in nature

This metal is present practically everywhere: in living organisms, soil, water, but in minute proportions. In deposits it is found in the form of nuggets, sand, thin veins and inclusions in the rock from noticeable to microscopic particles, indistinguishable without powerful optical instruments.

Chemical and physical properties

This is the first metal that humanity mastered. The substance is bright yellow in color, does not oxidize in air and water, and is inert towards most known acids and alkalis, for which it is called a noble element. It dissolves in concentrated perchloric acid. The famous aqua regia - a solution of hydrogen chloride with nitric acid - is widely used by jewelers as a gold solvent. It also reacts quite easily with a concentrated aqueous solution of bromine, fluorine, and cyanide. Forms an intermetallic compound with mercury in the form of a low-melting alloy (amalgam).

The physical properties of this substance are unusual - it is one of the rarest and heaviest (Au is 7th place in the periodic table) metals in the earth's crust. A cubic centimeter of pure gold weighs more than 19 grams. At the same time, the substance is very soft and plastic. It can be crushed with your fingers, rolled into a sheet 100 nanometers thick, and 1 gram can be stretched into the thinnest wire more than 2.5 km long.

The process of gold formation in nature

Scientists have not found agreement on the origin of this metal. The latest version is the explosion of a neutron star, after which dust formed consisting of heavy elements. It condensed and served as the basis for the emergence of the core of our planet, where the bulk of gold reserves are currently concentrated.

The metal that is found on the surface presumably got there during the heavy bombardment of the planet by meteorites or as a result of volcanic activity along with the eruption of magma.

Search for a nugget

For centuries, gold placers near rivers were eroded by gold-bearing rocks. Now you can get precious sand from the bottom. A good place to look for yellow metal is in small streams near mountains. From the slopes themselves, the metal falls into the water. Since gold is heavy, it settles into sand or pebbles. There it accumulates and a gold-bearing placer is formed. The best stream to search for is no more than 15 km away. In them you can find not only gold sand, but also nuggets.

To assess whether there may be gold in this stream, you need to pay attention to certain signs.

If quartz pebbles are found in the water, then there may be not only small, but also larger precious metals.

The surest sign is to wash the rock with a tray or bag. If you come across a small pebble that looks like gold, this is a good sign.

In order to choose a good site, it is better to ask local residents. Perhaps they will tell interesting facts about the nuggets that were found here.

Nuggets, which weigh up to one gram, are most often found under sand no deeper than 10 cm. Finding them is not so difficult. Gold weighing over 1 gram is found at a depth of 10 to 30 cm. After the sand there is soil, and there you can find a nugget weighing about 100 grams.

It is better to look for precious metals in more closed places, invisible to humans. If gold is found on the surface of rivers, it is in very small quantities. For travel lovers, gold mining is an interesting adventure. In the video in our article you can see how to search for precious metal yourself.

How gold veins are found

Previously, discoveries of new deposits were often random. A curious man in the street, attracted by the unusual golden color of grains of river sand or the suspicious weight of a stone, picked up an intriguing object, which turned out to be a nugget.

There is a known case where for decades a family in Siberia used a massive black cobblestone as a pressure when pickling cabbage, until a casual acquaintance with experience as a prospector recognized it as a huge nugget.

The first Russian deposit was discovered by the dissenter Erofei Markov, who found a nugget on the road and brought it to the factory office in Yekaterinburg.

Satellites of gold

This element is never found in nature in its pure form. The most common form is sulfides and arsenides. A total of 15 associated minerals are known - silver, rhodium, iridium, platinum, bismuth, copper and others.

Where is gold found in nature?

Nowadays, enough information has been collected about where deposits are most often found, which allows us to use a scientific approach in the search for gold-bearing veins. On an industrial scale, post-magmatic hydrothermal formations are of greatest interest, where there is a high probability of the presence of a placer deposit. In late portions of granitic magmatic melts, gold is also found in the form of inclusions. The mountain ranges are rich in this metal - the Urals, the Cordillera, the Andes.

Research in recent years has shown that bacteria can also accumulate gold in their cells. In the deposits of Kamchatka, Benin and South Africa, golden bacteria were found - particles of metal in the form of chains characteristic of these microorganisms, as well as the remains of armored growths of unicellular colonial algae and their cysts.

Some types of protozoan microorganisms are able to dissolve this metal, turning it into a bioavailable substance for other plants and animals.

Types of gold deposits

Based on the principle of formation, gold deposits are divided into endogenous (primary) and exogenous (secondary). The type of deposit does not affect its richness, location or physico-chemical composition of the gold ore.

- Primary, or ore, deposits. Primary, or indigenous, include ore deposits in areas where granitoids occur. Mining at such mines is a more labor-intensive process and is carried out using the shaft method. The development of such deposits began in the 20th century.

- Eluvial deposit. Belongs to the exogenous, or secondary, type. It is formed in places where the primary source emerges due to its destruction (weathering, erosion, leaching) and contains precious metal only a few tens of meters from the primary deposit. By looking at its gold content, you can get an idea of how high the metal content is in the rock.

- Colluvial placer. Also a deposit of exogenous nature. Under the influence of natural factors, the elements of eluvium (large pieces of rock) are destroyed even more, grains of native gold contained in the ore are released and washed away by water, settling as sand deposits on the slopes and in depressions of the relief. The source of such a deposit is both one powerful primary and several poor deposits. The placer may be located on the surface or hidden by a layer of waste rock.

Mining gold from sand

Earlier, in primitive times, gold was already known. It was mined in small quantities and then exchanged for food or things. How is gold mined from sand? Seekers offer some advice.

Previously, they took a tray with an angle and scooped sand and water into it. Gold mining in this way is still used today. Sand is much lighter than gold and it was washed off with water, but the precious metal remained in the tray.

Another convenient way is to work with bags. Sand is collected in them and water is poured into them. Since gold is 20 times heavier than sand, it will settle to the bottom. The water needs to be poured out. She will go away with the sand. All the precious metal will remain at the bottom of the bag. How to extract precious metal in a more modern way. After all, getting gold from sand is not so easy and quick.

Today, new gold mining technologies are being used. To do this, they take a metal detector, which was first used in Australia. Then the largest nugget was found, weighing 27 kg. It is possible to detect even a very small grain of gold with a metal detector. However, with the condition that it is no deeper than 20 cm from the surface. When metal is found, this tool emits a beep. Today there are even devices with a function that will ignore signals if another metal is present.

After the metal detector, mini-drags were invented. They are used in water areas. This device has an installation that itself supplies sand, washes it and extracts the precious metal.

Mini-sluice device - this technique washes the sand and extracts metal using the gravitational method.

If you are wondering how to mine gold not on land, but in a river, then keep in mind that searching with a metal detector is not suitable for you.

How, where and with what gold is mined can be seen in the photo illustrations. In addition, you can search for gold not only in summer, but also in winter.

Extraction methods

The development of modern technologies has allowed gold mining companies to increase the profitability of production and obtain gold from previously mined soil. But along with new technologies, long-known methods are still widely used.

How gold was mined in the old days

At the dawn of civilization, gold mining was limited to finding large enough nuggets from which jewelry was made. The oldest object found in Bulgaria and resembling a hairpin was made 6 thousand years ago.

artisanal

Later, they began to use the method of washing the soil with water, which made it possible to extract not only large nuggets, but also fine sand. The first miners used a gold pan as their main tool. The heavy metal settled at the bottom, and the lighter soil was carried away by the flow of water. This painstaking method is still used by “wild” prospectors to sift previously spent rock in abandoned deposits.

Transmutation

In the Middle Ages there was such a science as alchemy. It consisted of searching for the philosopher's stone, with the help of which it was supposedly possible to turn lead and copper into gold. Even the famous Newton spent three decades researching this method.

The first successful transmutation was carried out in March 1947 - artificial gold was formed from mercury isotopes in a nuclear reactor. This led to a collapse in stock exchange prices, but the panic did not last long. The cost of artificially produced precious metal was many times higher than samples mined even from the poorest mines, and this method did not have any economic potential other than scientific interest.

Of the breed

To extract gold from rock, it was necessary to first crush it for further washing. This method had low efficiency. However, in 1843 the Russian engineer P.R. Bagration proposed an option for extracting gold from ore by treating it with a cyanide solution, which significantly increased the volume of gold mining from ore deposits.

In sea water

Sea water can serve as a source of precious metal. Its concentration in liquid is small - no more than 0.16 g per ton, but on a global scale it is more than 25 million tons. For comparison: throughout the history of gold mining, humanity has received about 160 thousand tons of the precious metal.

Wastewater

In 1977, a method for extracting precious metals from wastewater was patented. The process included several stages: bacterial treatment to separate the sludge, its drying, combustion and exposure of the resulting ash to acids. The developer of the method, Markels, managed to achieve the separation of 90% of the gold contained in industrial and domestic wastewater. Processing 102 thousand cubic meters of wastewater yielded up to 164 grams of gold. The result was worse than expected and did not cover the costs.

From sand

Even ordinary sand on the bank of the nearest river probably contains some amount of the precious metal. Its volumes may not be enough to organize full-fledged mining on an industrial scale, but as an experiment or hobby, manually panning and obtaining a small amount of gold at home is a completely feasible undertaking.

Self-extraction methods

Particles of precious metal fall into river sand as a result of erosion of gold-bearing rock. Finding a solid nugget, given the scale of industrial search, is unlikely in our time. Sludge washing is now the main method of gold mining.

You can do it yourself, knowing the places with high concentrations of precious metal and how to separate it from sand at home.

Manual flushing

The method is based on the fact that gold is heavier than all other particles contained in the sludge. Due to this, the metal is separated using a special tray or bag, settling at its bottom. Grains of base metals (the so-called concentrate) are removed using a magnet.

Amalgamation

Mercury particles capture grains of precious metal, “wet” it, separating it from the bulk of the soil. After this, the sludge is removed, and the mercury is evaporated, drawn out with a plastic syringe, or dissolved in nitric acid.

The technology is dangerous for use at home. Inhaling mercury vapor is harmful to the human body. It is necessary that during amalgamation the room is well ventilated. It is advisable to use a mask and protective gloves.

Cyanidation

The method is used when the content of the element in the sand is very low. For purification, hydrocyanic acid is used, which is even more toxic than mercury. Inhalation of cyanide vapor causes immediate death. To prevent the formation of toxic fumes, the pH of the solution is artificially increased using alkali.

Which way is better

Cyanidation and amalgamation are quite dangerous manipulations to use at home. When washing in small volumes, the manual method is better. It does not require the use of chemical reagents; metal separation occurs mechanically.

Industrial gold mining technologies

Modern gold mining on an industrial scale, comparable to market needs, requires the use of advanced technologies. This makes it possible to increase the profitability of even those fields that were previously considered unpromising. Depending on the type of mine, two methods of its development are used.

Open way

The open, or quarry, method is used in the development of secondary or alluvial deposits. It is less expensive, since the gold-bearing rock is located on the surface and does not require crushing. The work is carried out in the warm season, but winter mining has its advantages - better accessibility to promising places hidden under water in the summer and water transparency, which provides a better visual overview of the sandy bottom.

Gold is extracted from sand by panning. Under the pressure of water, gold-bearing sand moves along special gutters with a relief bottom (dredges). The waste rock is washed away, and the gold, due to its mass, gets stuck in the depressions, after which it is collected and sent for further processing.

This extraction method has its advantages and disadvantages. The positive point is simplicity and low cost. The negative side is low efficiency. There is a high probability of missing large nuggets that are not stuck in the small cells of the dredge. To avoid such cases, the employee on duty carries out visual control of the process.

Closed method

The closed (mine) mining method is necessary when developing primary or primary deposits, when the gold-bearing vein goes deep underground. This method requires more complex and expensive equipment, blasting and processing of ore using various chemicals.

Amalgamation

The technique is based on the ability of gold to react with mercury. The crushed rock is moistened with mercury with the addition of lime, the resulting amalgam is separated from the ore, filtered and evaporated, releasing the gold. After this, the mercury is reused, and the noble metal, purified to 75–90% purity, is ready for further processing.

The method was known 2 thousand years ago and was widely used earlier. However, it is associated with a high degree of environmental pollution and is not effective enough. The degree of gold recovery is 50–70% of the total content. Also, the method cannot be applied if there are sulfides in the rock.

It is used primarily for secondary processing of rock after washing.

Heap leaching

The most common technique, now used in all fields. The gold ore is placed on a waterproof surface and treated with an aqueous solution of sodium cyanide. The resulting liquid is collected, the precious metal is precipitated using reagents and undergoes further purification.

Cost of production and laws

To search for precious metals legally, you need to obtain an appropriate license, valid for 5 years. To receive it, you need to register as an individual entrepreneur or register as a legal entity.

To engage in professional mining, it is advisable to have equipment for extracting sand from the depths of a reservoir, where the concentration of metal is greater. Only the state is allowed to sell jewelry. There are penalties for the illegal sale of gold to private individuals.

Profitability calculation

For mining to be economically profitable, you need to find a place with a high concentration of metal grains in the silt. Otherwise, there is a risk of wasting a lot of time, earning 50-100 rubles a day. For example, in most rivers near Moscow, a maximum of 0.6 g of gold is produced from 1 m3 of sand using manual technology. The profit from such production will be small.

To calculate profitability, the amount of expenses and the amount of future profit from sales are compared. Costs include:

- costs of time and money to search for gold-bearing silt,

- the cost of obtaining a permit for legal work,

- price of extracting gold from sand (consumables, equipment),

- transportation costs.

It is necessary to take into account the percentage of metal in the sludge and the difficulty of its extraction in specific conditions.

Illegal mining: what threatens black miners

For illegal mining and sale of precious metal to private buyers, and not to the state, fines of 3-5 thousand rubles are provided. If loot worth more than 1 million rubles is concealed, the Criminal Code comes into force. You should not look for metal where gold mining enterprises are already operating; you can also be punished for this.

In addition to a fine from the state, setting up your own workplace also poses a risk. Specialized equipment is needed that will allow mining without harm to health at home.

What happens next to the mined gold?

The mined metal still contains impurities. They are removed using refining. At the initial stage, the raw material is cleared of iron impurities and treated with nitric acid, while gold precipitates. Further processing is carried out using hydrochloric and nitric acids and evaporation. This method allows you to achieve a purity of the substance at the level of 99.95%.

To achieve maximum metal purity, electrochemical refining is used: hydrochloric acid in solution serves as an electrolyte, the anode is the raw material for purification, and the cathode is a gold rod of the highest standard.

Use of precious metal in various industries

The main industries in which this metal is widely used are:

- jewelry industry,

- creation of modern electrical appliances,

- optics,

- medicine,

- cooking,

- atomic research,

- production of weapons of mass destruction.

Only a tenth of the extracted noble element goes into industry, about 45% ends up in the gold and foreign exchange reserves of states and private individuals. The rest of the metal is used to make jewelry.

History of the development of gold-bearing veins

Archaeologists suggest that gold mining as a branch of the national economy originated in the Middle East. From there, jewelry was exported to Egypt. The first finds in Sumerian tombs are more than 3 thousand years old.

One of the richest cultures in gold reserves was the ancient Inca Empire, which was located in the territory of modern Mexico, Peru and Chile. Their legacy is the mythical golden city of Eldorado, in search of which the Spanish conquistadors went.

In the 15th century, the first deposits were discovered in Mexico, Chile and Ghana. Three centuries later, the first gold mining cooperatives appeared in Russia. In 1823, the richest veins were discovered in Canada and America, which was marked by the outbreak of the famous “gold rush”. Even later, deposits were discovered in South Africa and Australia.

Famous gold deposits

An interesting fact is that 90% of all gold production in the world is provided by the ten largest deposits. The richest and most famous include:

- Muruntau, Uzbekistan. According to preliminary estimates, it is 2.5 times more promising than the next field on the list.

- Grassberg, Indonesia.

- Pueblo Viejo, Dominican Republic.

- Yanacocha in the Cajamarca region, Peru.

- Carlin Trend, Nevada, USA.

- Goldstrike mine, which includes 3 deposits, USA.

- Cortez, Nevada, USA.

- Olympics in Russia, Krasnoyarsk region.

- Veladero mine in Argentina.

- Boddington Quarry, Australia.

Geography of production

The precious metal is mined in different countries. In 1980, the world stock was replenished by 944 tons. Of these, 675 tons were delivered from South Africa alone. In 1990, the share decreased and only 605 tons were produced. Western countries, on the contrary, doubled production and were able to extract almost 244 tons of gold.

Today, there are countries in which the development of the yellow metal has begun recently (in New Guinea, the Philippines and Indonesia). Significant gold mining can also be noted in Latin America. In those countries where there is cheap labor and electricity, the economy is booming, as are many industrial sectors, such as gold mining.

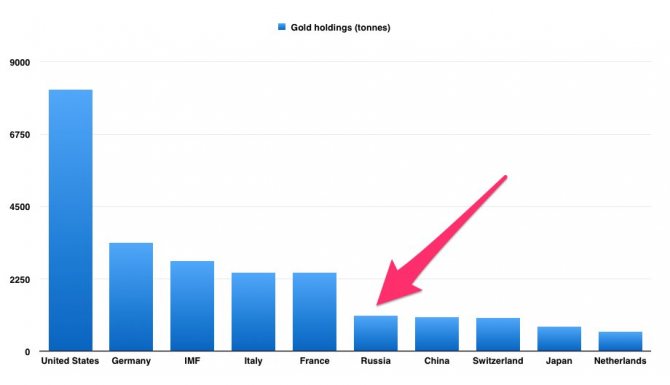

Gold reserves of countries as of 2015.

Already in 2010, China and Australia were among the leaders in the field. Thanks to them, almost 2,650 tons of yellow metal were collected. In the 21st century, Russia began to gain momentum and replenish its own reserve. Today it is noted that Russia is ahead of countries such as Great Britain, India and Japan. Now she is in sixth place in the world rankings.

There are many ways to mine gold. Read more about each below.

Profitability and laws

Gold mining on an industrial scale can only be carried out if the deposit is profitable - at least 3 g per ton of ore. If a mine cannot provide this level of metal production, it is recognized as unprofitable, and work on it is stopped.

Until 2021, individuals were prohibited from mining metal even in depleted deposits. Violation of the law entailed punishment including criminal liability. However, the law has been revised, and now gold mining can be carried out by a private individual who has registered an individual entrepreneur.

Extraction of valuable metal is subject to licensing by the Rosnedra organization. Before obtaining permission, the applicant will have to win this right at an auction, and the cost of such a license amounts to billions of rubles if we are talking about promising deposits.

Without obtaining a special permit, you can mine precious metal by concluding a contract with a gold mining organization to carry out work on its territory.

Profit today and prospects for the future

Gold is a measure of the well-being of entire states. As an investment object, it shows a steady increase in value year after year, which makes it an excellent source of investment. According to experts, this trend will continue in the coming years.

What things and materials can gold be mined from?

At home, you can also highlight gold, which is found in ordinary household items.

From electronic boards

Old Soviet devices contain some amount of noble metal. It is present in electronic boards, old microcircuits, transistors, capacitors and connectors. Modern technology - phones, tablets, computer parts - also contain gold.

From dishes

Expensive sets, especially those produced during the Soviet era, are often decorated with thin strips of gold leaf, which can also be removed.

Where to look for and mine gold

Most often, its increased content is observed in the sand of mountain rivers flowing through deposits of the precious metal. The presence of the element in water and sludge can be found out from local residents or through the use of special detectors. If precious metal mining has previously been carried out in the area, it makes sense to check its concentration.

You can mine gold not only in summer, but also in winter. In winter, this is even easier to do - the water level in the rivers decreases, and particles of the precious metal settle in large quantities on the slopes of the banks. In summer it is extracted from silt raised from the bottom of rivers.

For novice seekers, it can sometimes be difficult to distinguish gold from pyrite - this is a similar mineral in appearance, which can also be contained in sand. Pyrite particles have a cubic shape, unlike gold, the grains of which can take any shape.

How to extract gold at home

There are several methods suitable for use by individuals.

Electrolysis

If you have minimal school knowledge of physics and chemistry, the electrolysis method is applicable in a home workshop. To do this, you will need hydrochloric acid as an electrolyte, a thin 999 gold wire as a cathode, and objects containing gold as an anode. When an electrical voltage is applied, the precious metal will dissolve and deposit on the cathode.

Etching

Selected parts containing noble metal are filled with a heated solution containing nitric and hydrochloric acids (regia vodka), after which the dissolved gold is precipitated using a reagent.

How to use a gold pan

Using a tray, precious metal is mined in the traditional (manual) way. To do this, sand is lifted from the bottom of the reservoir and placed in a tray. The best depth for work is 15 cm. Then the tool is immersed in water and circular movements are performed.

The sludge is washed, leaving light particles that do not contain metal. Final purification with separation of heavier fractions can be carried out at home. How to extract grains of gold from sand is described above.

Next, watch a visual video of one of the methods of gold mining: