Share on social media networks:

Every year, jewelry is becoming more and more popular in the market, and in cities the number of salons and stores selling jewelry is increasing, although the extraction of raw materials and production are declining. The most sought after and popular, of course, are gold and silver, and of all types of the latter, blackened silver, products from which are distinguished by their sophistication and beauty. Silver is durable, inexpensive, and does not age a person, so it can be worn by both adults and children.

Types of silver and their uses

Unlike the noble metal gold, the appearance of silver does not have variety. Silver always has a white-silver color, but gold can be yellow, pink, red, etc.

However, there are different types of silver:

- Matte.

- Filigree.

- Sterling.

- Coin.

- Blackened silver.

Each type of metal has its own characteristics:

- Matte silver does not have bright patterns. This type of metal is obtained through the use of various emulsions, applying them to raw materials. This technology gives the metal some roughness. This type of silver looks very beautiful and original.

- On filigree silver, unlike matte silver, on the contrary, various multiple openwork patterns are created. This is achieved due to the fact that silver has high strength and malleability, which allows the production of thin threads. They, like wire, give the products a pattern. This technique for making products requires special skill, craftsmanship and a lot of time. There are openwork filigree and background filigree. In products made from openwork filigree, the pattern has a cross-cutting character, and in the case of background filigree, the lace pattern is attached, so to speak, to the background, which is, for example, a moonstone.

- Sterling silver is the main material for jewelry. This type of metal has a smooth surface, white-silver color, and is highly durable. Sterling silver is made up of 92.5% pure metal, with the rest being a copper additive.

- Blackened (scarlet) silver - what is it? This material is obtained as a result of a chemical reaction of the metal with sulfur, which is contained in microdoses in the air. Pure silver is almost inert to sulfur, so the reaction occurs too slowly. As a rule, products made from precious metal alloys darken quickly, since copper is less resistant to sulfur and reacts with it more quickly. Blackened silver comes in two types: the first is formed naturally, and the second is formed by the hands of a jeweler.

The history of blackened silver

Since ancient times, craftsmen and craftsmen have decorated household items and weapons with various ornaments, patterns and designs. Constantly improving in this area, craftsmen invented a special method of metal processing - blackening silver (at home today many craftsmen perform this to decorate their objects).

Important! Niello is an ancient technique of giving gold and silver jewelry a black color. After using this technique, the surface of the product becomes more contrasting and richer, be it a relief detail or an ornamental design. The same technology is also used to hide minor defects and connecting seams.

Creation principle

The essence of blackening is this: an alloy of silver, copper, lead, and sulfur is smelted into the base metal. The alloy for blackening is melted into recesses applied to your choice:

- Engraved.

- Minting.

- Hollowing out.

- By etching.

The recesses are made small - 0.3 mm. Under the influence of high temperatures, a chemical reaction occurs between the melted mixture and silver. In addition to decorative qualities, products blackened using this technique also gain practical properties: the decorations do not fade and do not require special care. And the palette of blackening can be varied: from silver-gray to black-velvet tone.

Important! Blackening also looks very beautiful on gold, but it is extremely difficult to deduce the composition of niello on a noble metal. Therefore, niello on gold is extremely rare. On metals such as copper, brass and low-grade silver, niello crumbles and falls off, therefore, from ancient times to the present day, only silver nielloing is most often used - it is durable and exquisitely beautiful.

Where is silver blackening done?

Deliberately changing the type of metal became widespread in the 17th century. Blackened silver gained great popularity in Veliky Ustyug (Russia), where the folk craft originated.

Important! An extensive exhibition of products by craftsmen from Ustyug is kept in the State Ethnographic Museum. The most famous exhibit of the collection is a cast cross, which is not only made of blackened silver, but also gilded.

In the European part of the country, jewelry and household items made of blackened silver were very popular in the 17th and 18th centuries. The works of master Mikhail Klimshin from Veliky Ustyug were especially famous.

Important! It has become fashionable and prestigious to have dishes, cigarette cases, trays, glass holders, snuff boxes, cutlery, and engravings made from this metal. Silver objects depicted various ornaments, pictures of hunting, cities and geographical maps.

At first, objects made of precious metal were made in private workshops, and then industrial production began in special factories. Since that time, ordinary people, including merchants, began to be taught the craft of silver blackening. There has always been a demand for silver, and today you can still find real works of art that are simply priceless.

Method number 3

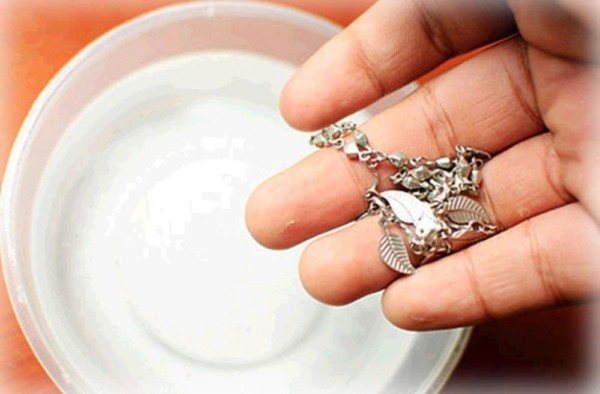

Blackened silver can be perfectly tidied up at home using the following “tools”:

- ammonia;

- dentifrice;

- cotton wool;

- thick napkin.

The container is selected taking into account the size of the product. Ammonia and tooth powder are poured into it - in such proportions that the resulting consistency resembles sour cream.

Cleaning begins by applying the prepared mixture to the surface of the silver item with a disk or cotton ball. As soon as it dries, you can start rubbing the item with a special napkin.

Blackened silver. What it is?

Blackened silver as in the photo is pure silver coated with niello using a special technology. The product is first minted, engraved, and then degreased and a special coating composition is applied. And in order for the niello to melt and cover the surface, the product is specially heated to a certain temperature.

Silver blackening techniques

Over the years, a lot of techniques for creating dark patterns on metal have accumulated. Here are just three of them:

- The German roughing mixture recipe involves slowly pouring lead into a copper-silver alloy, stirring thoroughly. Then, the resulting ternary alloy is poured into heated sulfur powder, thoroughly mixing for high-quality interaction of the components. The resulting mixture is poured into water, after which the frozen pieces of niello are finely and thoroughly ground in a porcelain mortar in the required dose. Fresh, damp blackening mass is applied to the object.

- The Russian recipe recommends adding sulfur to the alloy in portions, rather than adding the ternary alloy to the sulfur powder, as in the previous recipe. In addition, the finished mobile is not poured into water, but onto a cast-iron frying pan. The resulting solid “pancake” is crushed into pieces and then melted, adding sulfur and flux. If extra-class rabble is needed, the process is repeated three times. The prepared rabble is pounded in a mortar and sifted through a fine sieve.

- Recipe by Professor A.G. Spassky. The author worked at the Moscow Institute of Non-Ferrous Metals and proposed the following method for preparing niello: separately prepared silver sulfide, copper sulfide and lead sulfide are fused together in the required proportions. Afterwards, the resulting mixture is melted and cooled in a strictly defined way.

Methods of applying niello

Silver blackening can be done:

- Dry method. The surface of the product is moistened with the necessary solution, after which very finely ground black powder is applied. After this, the products are dried and fired in a muffle at a temperature of 300-400 degrees Celsius.

- Wet method. The composition is applied to the surface in the form of a creamy slurry diluted with water. Using a spatula or brush, apply the mixture thickly and tightly into the recesses. Next, wait until the water evaporates. When heated in the muffle, the applied composition melts and flows into the pattern, covering the object. After all procedures, the product is removed from the oven.

Important! Small products can be melted with a soldering gun, the heat flow is concentrated on the base metal from the reverse side. After the mixture has melted, heating is completed.

After the process of applying black, the product is “cleaned up” by scraping or processed with a file until the design appears. This must be done very carefully so as not to catch or deform the ornament itself. Then all that remains is to sand and polish the product until the entire pattern appears.

Blackening on silver

Veliky Ustyug gained worldwide fame due to the famous “northern mob”. Chern is an alloy of silver with copper, lead and sulfur. The powdered composition is rubbed into the grooves of the pattern engraved on the silver object. When fired, the niello is firmly fused with the silver surface, giving rise to a black graphic design. It is complemented by engraving, embossing, gilding, shotting of the background - embossing with a special sharp tool that creates a grainy texture of the metal surface. The strength of adhesion to silver and the shade of black depend on the method of preparing the niello and the proportions of its components. The people of Ustyug had their own secret composition. Northern niello differs from other similar centers in its particular strength and rich range - from ash-gray to deep black.

Northern niello is characterized by a particularly strong niello composition, the proportions of its constituent parts were preserved as a professional secret by generations of Veliky Ustyug craftsmen. The stylistic features of their work influenced the works of the masters of Arkhangelsk, Vyatka, and distant Tobolsk.

As you know, blackening on silver has been “living” in Russian art since the times of Kievan Rus. In the 16th – 17th centuries, this art received its greatest development in Moscow. Of the three historically established centers of blacksmith art - Moscow, Dagestan and Veliky Ustyug - the latter is distinguished by the highest level of execution and exquisite sophistication of products.

Silversmiths worked in Veliky Ustyug already in the 17th century, but the highest flowering of the art of the mob in this city dates back to the 18th century, when the Baroque style occupied a dominant position.

The art of the northern mob from the 18th to 19th centuries cannot be considered professional art. Rather, it occupies an intermediate position between professional and folk art, in which, as is known, there are exceptionally stable local artistic traditions that largely neutralize the influence of the stylistic trends of the era. The products of the Ustyug masters of the Baroque period are emphatically massive, their forms are plastic, with smooth contours, rounded corners, which is perfectly combined with the softness of the engraving, creating the impression of the plasticity of the niello design.

The largest artist of the northern rabble in the 18th century was M. M. Klimshin (1711 - 1764), who with his work laid the foundations for technical techniques and artistic solutions that became traditional in Ustyug niello art. Two unique works give an idea of the work of the outstanding master of his time, Mikhail Klimshin. One of them is the staff of Veliky Ustyug Bishop Varlaam, executed in 1750. Along the entire barrel of the staff there are images of gospel scenes framed by ornaments; An inscription is carved on the figured handle confirming the name of the owner and author of the item. Klimshin reveals even greater mastery of composition in a small snuff box from 1764. The lid and each side are decorated with miniature paintings - scenes of a parade ride, falconry. Dark figures of people appear as clear silhouettes against the background of landscape or architecture. The images are made in Klimshin’s characteristic thick black. This wonderful work showed all the features of the master's style - the elegance of the design, the richness of light and shade and texture in detail, the shotting of the background, the combination of silver with soft matte gilding.

The theme of the drawings of niello products of this period was characteristic: pastoral scenes, park landscapes with architecture, etc. In the 70s of the 18th century, a new theme appeared, glorifying the famous victories of the Russian army and navy, panoramas of Veliky Ustyug, Arkhangelsk and Vologda.

On a round snuff box from the collection of the Russian Museum, framed by a black grid of meridians and latitudes on a golden background, there is a map of the Vologda governorship. The rivers are carefully drawn in black, their names are written, the cities are indicated with miniature outlines of buildings. The reverse side of the snuff box contains numerous statistical and geographical information about the area. The simplicity and severity of the form of the object and the peculiar rationalism of its decoration met the requirements of the classicism style. This work was completed in 1794 by another outstanding Ustyug master, Ivan Zhilin.

The residents of Ustyug expressed their love for their city in numerous panoramas placed on a wide variety of objects. One of the major hereditary masters of the 19th century, Mikhail Koshkov, decorated a set of teaspoons with views of the city. Despite their miniature size, the finely engraved landscapes reliably convey the main architectural ensembles of the famous Veliky Ustyug embankment. The successes of the Ustyug residents prompted Vologda masters to make similar attempts. In 1837, Ivan Zuev placed a view of the Vologda St. Sophia Cathedral on a smooth background of a silver tray. The fine line engraving depicts not only the architectural landscape, but a kind of genre sketch of the city of that time.

Later, at the beginning of the 19th century, the then dominant style of classicism manifested itself in northern blacksmith art. In the products of Ustyug niello masters, the golden background characteristic of the Baroque style disappears, the design becomes strict and laconic. The shapes of the products are also transformed, acquiring simplicity and some versatility, which was not observed in the products of the Baroque period. The soft tonality of the transitions of the black drawing is replaced by contrast, the graphic nature becomes characteristic, and details are clearly drawn. The spatiality and depth of the black drawing completely disappear, and they are replaced by the flatness of the images. Images of garlands and military emblems characteristic of classicism, especially its final period, become typical. At the same time, in the drawings and products of the northern mob from the time of classicism, features inherent in folk art are clearly manifested, such as decorativeness and richness of pattern, traditional completeness of compositions.

In the second half of the 19th century, the mob gradually lost the high level of unique art. Artistic creativity slowly turns into a craft, and at the beginning of the 20th century, the northern mob essentially ceases to exist. Secrets and professional skills are preserved only by a few masters of Veliky Ustyug. However, unique art has not completely disappeared. Already in the pre-war years, the “Northern Mob” artel worked in Veliky Ustyug, the leader of which for many decades was the Honored Artist of the RSFSR E.P. Shilnikovsky, an outstanding engraver and artist, the creator of the ornamental movement in the art of the Northern Mob. He owns more than three hundred drawings for blackwork and his own original works. The “Golden Hops” stack, which was repeated more than once by the author, became very famous in its time.

Today, “Northern Chern” has developed into a large enterprise where professional artists, based on the best traditions of the art of blackening, fruitfully developing them, create products that are in constant demand and success in many countries around the world.

Where can I buy

Shop "Vologda Souvenirs"

Address: Vologda, st. Chekhova, 12, 2nd floor Phone E-mail Official website: volsuvenir.ru

Souvenir shop JSC "Northern Mobile"

Address: Veliky Ustyug, st. A.Uglovskogo, 1 Phone: (81738) 2-48-77 E-mail Official website: www.sevchern.ru

Methods for blackening silver

To obtain “blackness” on silver products, it is necessary to achieve the effect of sulfur deposition on the surface. You can do this in the following ways:

Mechanical

Mechanical is the easiest way to blacken silver at home. To implement your plan, you will need graphite mixed with iron oxide and turpentine.

The mixture of ingredients is applied in the form of a paste to silver objects and wait until completely dry. Remove the product from the product with a soft brush or suede cloth. After which, the protruding parts of the object are wiped with alcohol.

Important! As a result of this technique, silver items turn out to be artificially aged.

Disadvantages of this method:

- Minimal adhesion to the surface of the product.

- Used for small amounts of decoration.

- It is very easy to clean such products from blackening.

Chemical

Chemical is the most durable and effective. The principle of this method is to fill the engraved areas of the product with a mixture of niello. We described this method in detail above.

Galvanic

Galvanic - used in production and requires special equipment. The essence of the method: metal oxides are deposited on silver objects in special baths by electrolysis. One charge is created along the perimeter of the bath, and another charge is created on the alloy. As a result, plus and minus are attracted and create the necessary shade for the object.

Industrial blackening of silver

In their workshops, jewelers carry out blackening on silver using one of the following methods:

- Mechanical. It involves mixing iron oxide and graphite, and then adding turpentine to this mixture. Then carefully cover the product with the resulting substance, wait until it dries completely, and wipe the entire surface with a suede rag pre-moistened in alcohol. Interesting! Electroplating is one of the subtypes of mechanical blackening of silver. In this case, the electrolysis method is used. But products on which niello is applied in this way quickly lose their attractive appearance, since the coating wears off after a short time.

- Chemical. It is carried out using a powder that includes silver, zinc, lead and sulfur. It is poured into all recesses of the product, which, together with the substance, is heated to the required temperature. Due to the heat, the powder begins to melt, firmly ingraining itself into the jewelry. Then the jewelers can only grind and polish the product.

You may be interested in: 999 silver – how much does 1 kilogram cost?

Blackening silver at home

Of course, no one will make a galvanic bath for one bracelet or ring, but what to do if you want to have earrings made of blackened silver, but only ordinary ones are available? There are many simplified methods used at home that are used if you need to blacken a chain or vase. Of course, blackening silver at home is extremely harmful and smelly, but if the desire to act is uncontrollable, then we suggest you use the following recipes and methods.

Method No. 1

To prepare the mixture you will need:

- Egg.

- Tightly closing plastic container.

- Fishing line or thin thread.

Use prepared items as follows:

- Clean the silver item from contamination.

- Boil an egg.

- Cut the egg in half.

- Place two halves of the product at the bottom of the container.

- Hang your silver jewelry on a string.

- Leave the product in an airtight container for at least 30 minutes.

- Turn the decoration over from time to time to ensure uniform blackness.

Important! The principle of operation is based on enveloping hydrogen sulfide vapors released from the product or decoration. The resulting coating is durable and stable. This method can also be used for products with precious stones, but after the procedure of blackening silver at home, carefully wipe the stones so that they do not lose their natural shine.

Method No. 2

To blacken the product, use iodine:

- Apply iodine to the jewelry using a cotton swab.

- Leave to dry in the sun.

- Polish the jewelry. Apply toothpaste to a cloth and wipe the product: in convex places the silver will remain light, and in hard-to-reach, embossed areas - dark.

Important! Use this method only for jewelry with intricate designs and it will look exquisite, do not use this method on flat items as it is not effective in this case.

Method No. 3

Sulfur ointment will give silver items an antique look. Use the product as follows:

- Coat the item completely with ointment.

- Heat the product with a hairdryer. As it heats up, a black-purple tint will appear on the surface.

- After the blackening process, polish the jewelry.

Preparatory work

You can restore the original appearance of other types of products without risk at home. Below are four of the simplest and most accessible methods for each of us.

Before you start cleaning blackened silver using one of these methods, you need to remove all kinds of dirt from the surface of the product: grease and cosmetics, sweat and dust.

And you can do this using:

- dishwashing detergents;

- toothbrush;

- warm water.

In order to properly dilute the detergent in warm water, you can use a glass or ceramic container.

The dish is filled with water, after which the product is immersed there.

To properly clean an item from stubborn dirt, you need to leave the item in the dish for about twenty minutes. You can remove all the dirt well with any soft-bristled brush.

It allows you to completely remove all the most visible gross dirt. After this, the product is washed in warm water.

The first stage of cleaning at home is the same, regardless of which method will be used next.

Caring for blackened silver items

The beauty of antiqued pieces is that they don't need to be cleaned and don't need polishing. However, it is still necessary to remove dust and dirt from jewelry from time to time. This must be done extremely carefully so as not to remove the top layer. Use canvas rags and simple detergents for the cleaning procedure, the main thing is that they are not aggressive.

Important! Do not use harsh chemicals such as ammonia or acetone for cleaning. Do not boil blackened jewelry or polish it with products containing sharp abrasive particles.

Let's look at a few simple ways to clean jewelry:

- Use a soap solution with a pinch of soda. Place the jewelry in the solution for 15-20 minutes, and then rinse the items under running warm water. Wipe the items dry.

- Pour cold water over peeled and chopped raw potatoes. Leave the jewelry in the container with the product for 3-4 hours. Rinse items thoroughly and wipe with a soft cloth.

- Dissolve 15 g of soda in a glass of water. Wash contaminated items in the solution.

- Remove dirt on the surface of the object with an eraser. Rinse the decoration.

Silver with blackening: care rules

The peculiarity of blackened products is that they do not require too frequent cleaning and polishing. But sometimes you still need to remove dirt and dust from them.

There are several gentle ways that do not harm such items:

- A solution of soapy water and a small amount of baking soda. It should be warm. The jewelry is immersed in the liquid for 10-15 minutes, then washed with warm water and wiped dry.

- Potato infusion. Peel one potato, cut into slices and cover with cool water. Immerse the product in a container with potatoes for 4 hours, rinse with water and dry.

- Dissolve one teaspoon of baking soda in a glass of warm water. Wash silver items with this solution.

Items made of blackened silver should be treated with care and precision. If this is jewelry, then it should be stored separately from other jewelry in a tightly closed box. Then it will retain its sophistication and perfection for many years.

You may be interested in: Silver: chemical and physical properties, scope of application

How to distinguish blackened silver from oxidized silver?

Blackening of silver is a very labor-intensive and complex process, which is why the price of this type of metal is much more expensive than ordinary silver. But it is very difficult to find blackened silver among oxidized silver.

Important! At its core, oxidation is the coating of metal with a film that protects it from tarnishing and adds sophistication to the product. However, the oxide film will not make the jewelry high-quality and durable; on the contrary, after purchase, the product may lose its original appearance in a very short period of time.

To avoid regretting your purchase, take a close look at the decoration:

- Products coated with an oxide film look too smooth and only slightly darkened. Blackened silver has a rich black color that blends with lighter areas.

- The patterns on items made of blackened silver look very noble and are made neatly.

- Real silver with blackened elements is more expensive than other types of precious metal. The price of the products includes: silver standard, complexity of the pattern, presence of precious stones, blackening technology, complexity of the craftsman’s work.

- When cleaning oxidized silver, white areas appear on the product, but blackened silver is resistant to both cleaning and polishing. Such a metal can lose its blackness only through prolonged boiling or immersion in acid.