The essence of the refining procedure

To extract pure silver, special technologies are used to purify it from various impurities, the totality of which is called refining. Silver is purified in various ways, which consist of several stages, stages to remove excess impurities. Each of them uses its own physical and chemical refining methods for dissolving and separating this element from other substances.

Ways to clean silver yourself at home:

- chemical;

- cupellation;

- electrolysis.

Silver refining at home

The raw materials used are:

- jewelry scrap;

- sludge from electrical silver cleaning;

- “silver foam” – waste from lead purification;

- technical silver – radio components, etc.

The essence of the silver purification method

Silver refining is considered to be a combination of various technologies used to purify the metal from foreign impurities. Until recently, it was possible to carry out such events only at industrial enterprises involved in the production of high-grade silver. Now many people practice silver refining at home. If you know the intricacies of processing ferrous or non-ferrous metals, then there will be no difficulties with refining silver, because these procedures are similar to each other.

The most commonly used cleaning products are:

- decorations;

- technical silver from radio components;

- unwanted jewelry that is left without a pair or is simply unsuitable for wearing

- waste generated during lead refining.

The choice of DIY cleaning method depends on the following factors:

- amount of starting material;

- condition of the metal being processed;

- the need for continuity of the process.

When processing quality products, it is better to use the electrolyte method. It is suitable for the continuous production of large volumes of high-quality silver. The purity of the raw material is achieved due to the absence of redox reactions during refining.

If the silver is in the form of a solution, then it is recommended to use the chemical method. Sometimes it is possible to carry out refining using an electrochemical method.

Cupellation is suitable for cleaning low-grade alloys. With its help, you can finish pure silver much faster and more efficiently.

The cleaning procedure using any of the methods is carried out in several stages. During each process, the necessary raw materials are separated from the main composition.

Refined silver

Necessary tools and materials for refining

To refining silver chemically you will need:

- special glassware;

- quartz stick;

- nitric and sulfuric acid;

- ammonium chloride;

- sodium sulfide;

- salt;

- paper filter;

- funnel;

- deionized water;

- scales;

- copper scrap or zinc powder;

- special protective equipment - gloves, goggles, gown, respirator.

For cupellation:

- bake;

- crucible;

- lead.

For electrolysis:

- power unit;

- insulation tube;

- brass stick;

- stainless steel fork;

- insulating tape;

- tea filter (bag);

- plastic container (can be from a bottle).

Refining methods at home

The choice of method depends on the quantity, condition of the raw materials and continuity of production. The chemical method of refining silver is easier to perform, but the output produced is silver that is not always of a high enough standard. Low grade, with an admixture of other elements comes out during cupellation. The purest, highest quality is obtained by electrolysis.

Chemical method No. 1

Nitric acid, deionized water, scale, glass container and quartz rod for silver refining

Objects containing silver are placed in nitric acid. To do this, prepare a mixture of water and acid (1:1 ratio) and stir with a quartz stick. The dissolution of the metal occurs over several hours. The solution turns blue and silver nitrate is formed.

The next stage is the formation of silver plaque from its nitrate. To do this, copper scrap (pipes or other objects) is used, which is first thoroughly cleaned of deposits and contaminants. Copper acts as a catalyst.

After placing copper pieces into the solution, they are quickly covered with a white coating - silver cement. It must be periodically removed and shaken to the bottom of the jar. Copper gradually dissolves in silver nitrate and therefore, if necessary, it must be added until the reaction completely stops.

Then the solution is filtered, the cement is washed several times with clean water, dried well, and collected into a single piece when heated in a crucible. The metal turns out to be of low standard (up to 980), so it must then be further purified by electrolysis.

Chemical method No. 2

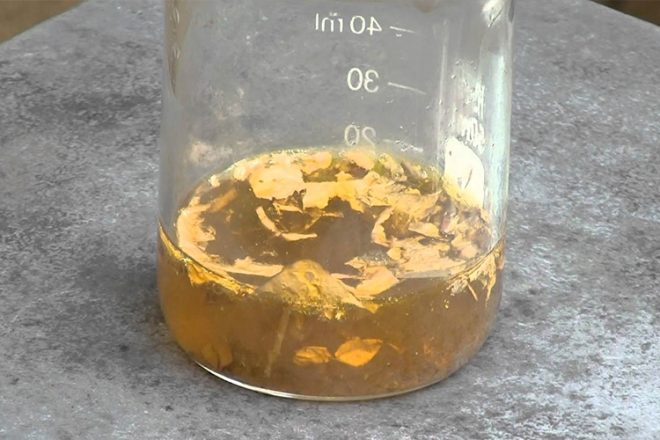

"Wet" method of silver refining

Technical elements containing silver are immersed in nitric acid. The liquid gradually turns blue. Then the silver solution is poured into another container, and table salt is gradually added to it while stirring. A chemical reaction occurs and a white precipitate falls to the bottom - silver chloride.

When the reaction ends, the water must be drained. Sulfuric acid is poured into the resulting precipitate to separate it into pure metal and its salt. Then zinc powder is poured in. After its complete dissolution, silver cement is evaporated from sulfuric acid, which precipitates. It is washed, dried, and melted into an ingot. The result is a white precious metal of 99%, the highest standard.

Cupellation

Melting silver in a crucible

Silver refining using this method is based on the unique ability of lead to oxidize. Then it, along with other impurities, is separated from the silver. But gold and platinum group metals remain, and then they need to be separated by other methods.

Cupellation is carried out in a preheated oven, which is covered inside with marl - a porous clay enriched with limestone that absorbs lead oxides. A bowl-shaped crucible with a lead-silver mixture is placed inside. When it is completely melted, air flows are launched to oxidize the lead. The output is an alloy with a rainbow shimmer, which is poured into molds.

Electrolysis

To obtain silver of the highest standard, the white metal is refined by electrolysis. To do this, an electrolytic bath is constructed from a plastic container, which is filled with a solution of nitrate of this white precious metal, diluted with water in a 1:1 ratio.

Silver refining by electrolysis

The bar obtained from silver cement using the previous method is placed in a filter bag. First you need to weld a loop of silver wire to it, to which the silver ingot will cling to a brass stick. It is threaded along the edges of the filter bag and is located above the bathtub. The place where the silver loop and the bar are welded must be above the liquid level so that the metal does not dissolve.

The stainless steel fork is bent so that it can be hung on the side of the bath, the handle is wrapped with electrical tape. The “minus” cable is connected to the plug placed in the bath, and the “plus” cable is connected to the brass stick. The voltage should be no more than 8 V, power up to 5 A.

After turning on the power supply, the reaction begins immediately. The bar decreases in size, and the walls of the bath are covered with crystals of purified white metal. They need to be broken off periodically so that they do not reach the filter bag, to prevent short circuits. After the process is completed, debris remains in the filter, and clean crystals must be collected from the walls of the container, dried and fused into an ingot. This refining of silver produces 999 fine metal for the manufacture of jewelry.

Cupellation

Cupellation is used in the refining of low-grade alloys. This method does not allow the separation of platinum and gold; silver is mined from alloys with lead. This method uses a special marl-lined oven with a cup-shaped crucible.

The method is based on the ability of lead in an alloy with silver to oxidize in air and separate from the metal along with impurities. Marl is a porous limestone clay that absorbs lead oxide. During the cupellation process, lead oxide evaporates under the influence of air flow. Refining is considered complete when the alloy surface has a rainbow color. When this type of paint cracks, you can see the bright shine of the silver metal.

Filtering stage

Necessary Items for Silver Filtration

To separate silver from the solution after the chemical refining procedure, you will need filter paper and a funnel. The solution with silver cement is poured into a container through a prepared filter - the copper salt flows off, and white metal remains on the parchment in the form of cement powder. This filtrate must be additionally washed several times with distilled water.

The drained solution contains a small percentage of silver, which can be extracted by adding table salt. After some time, a cheesy sediment will appear - silver cement.

All the resulting silver powder is dried and then fused. To avoid loss of silver dust, equal proportions of borax and baking soda can be added to the top of the crucible, which will create a protective glassy film.

In this way, a low-grade silver alloy is obtained. Next, it is necessary to carry out electrolytic refining to purify the white precious metal to a high purity.

Filtered liquid

| When the chances are zero, they look for gold in the ashes! Leonid Filatov. — About Fedot the Sagittarius |

“ A long time ago, in a distant galaxy

”... there was a fire in the workshop. There was no one nearby, and when the fire was noticed, it was too late to put it out. An acquaintance suffered significant losses because of this (products made of silver, brass, bronze disappeared without a trace... as if they never existed). Only the ferrous metal survived the fire.

But when dismantling the ashes, we managed to find a couple of steel boxes in which jewelry and “archeology” were stored (ancient jewelry, mostly made of silver, but there was a couple made of something, tin-lead or something, I don’t remember...). All this melted into one awkward ingot.

In general, the task: to isolate pure silver from the alloy. Powder, or melt. There was also a gold ring there. But it was preserved almost exclusively in the form of one yellow puddle (you can see it in the penultimate photo).

|

|

|

Having weighed the alloy, I figured that if we take it for pure silver, which, of course, is the majority in the alloy, then: based on the weight of 350 grams of metal, we will need about 300 grams of nitric acid (which will need to be diluted). Nitric acid with a concentration of 70% was available, which means that 350 ml after dilution should be enough.

I did all the calculations in my head, offhand. No precision was required, because the alloy definitely contains not only silver and gold, but also copper, and lead, and God knows what else...

In total I took 0.5 liters. Again, offhand. Dissolves - good. If it doesn’t dissolve, I’ll add it.

The very concept of “dilute acid” is very loose.

I once dealt with 5% nitric acid. So, in order for silver to begin to dissolve in it, heating was required (of course, the reaction proceeded without it, but on the verge of noticeability).

I decided to dilute it by half, that is, to 35%. I poured 0.5 liters of boiled water into the acid.

I abandoned the rafting. Here it was worth doing the opposite: first put the metal in, and then fill it with acid. Silver is a heavy metal, and falling pieces into liquid produced splashes and splashes. And out of habit, I worked not only without gloves, but also without glasses.

Dissolution began immediately. During the reaction, nitrogen oxides are released, so I either put on a gas mask (when I was nearby for a long time) or held my breath (when I was outside the room and sometimes came up to look). Of course, it is better to do all this under traction [K1].

The reaction accelerated, resulting in the release of “brown gas” (NO2) becoming more and more noticeable. Which indicates excessive consumption of acid. To avoid this, I added water. (The brown gas didn’t disappear completely, so I added more water afterwards; it wasn’t caught on camera).

The reaction was completed only after a day.

Some pieces remained from the alloy. Not much, but probably about 50 grams. I filled them with 70% acid. First, some kind of dispersion dissolved. This deceived me - it seemed that there was a reaction. But things didn't go any further.

Then: I filtered the solutions, washed the precipitate and filter with water [K2]. For filtering I used an improvised Buchner funnel - a plastic bottle in which I drilled a dozen holes (in the lid) and cut off the bottom. Use a piece of cotton wool as a filter. The convenience is that you can fill the entire volume at once, rather than adding “half a glass” periodically.

To precipitate 350 grams of silver converted into nitrate in the form of chloride, about 200 grams of sodium chloride will be required. 200 and took it. Too much here is harmful (silver chloride gives a soluble complex with an excess of precipitant - with the chloride anion), so it is better to carefully calculate everything.

The source of chloride is rock salt. I didn’t bother too much with cleaning, I dissolved the sample in water and let it sit. Some large crystals did not dissolve and settled to the bottom along with the turbidity. Since chloride is already in excess, you can “turn a blind eye” to such trifles.

Almost the entire salt solution was poured into the silver nitrate solution. I let the chloride settle slightly and stirred. I added another drop of salt solution, but there was no reaction (additional portions of sediment did not fall out). This means that all the silver is already in the sediment.

The precipitated silver chloride was washed by decantation several times.

I decided to use zinc for restoration. The option is far from the best, but it is simple.

Silver chloride was acidified with hydrochloric acid. The acid is old, unknown concentration. I used a piece of zinc weighing 195 grams. Large pieces are very convenient: I remember how I had to look for zinc granules in silver powder by touch...

Recovery was going well. Stirred occasionally. The solution remained hot for 8-10 hours. In the morning there were no signs of a reaction.

Zinc extracted. Dried and weighed. 117 grams. It’s not difficult to estimate that there is definitely at least 200 grams of silver. I added a little hydrochloric acid to the silver powder (just in case there was dispersed zinc left).

But has the silver chloride been completely reduced? - I doubted it. The fact is that I recently made silver nitrate. To do this, the precipitated silver chloride was reduced with zinc in an acidified solution with hydrochloric acid. Everything went well. The reduced silver was washed with dilute hydrochloric acid, then with water. Filled with nitric acid. And the trouble became visible: the silver instantly dissolved, but the silver chloride remained. There was a lot of it, I think, 10 percent of the original.

I had to filter the nitrate solution and then restore the silver again. This time I used a dubious, but, as it turned out, effective method. A solution of sodium hydroxide and sugar (hydrolyzed) is added to silver chloride. The silver thus restored was washed and dissolved in nitrogen without a trace.

I did the same this time. Alkali was added to the washed sediment. Then a solution of hydrolyzed sucrose was added. There was no reaction.

I washed the reduced silver thoroughly with water.

It was decided to conduct an analysis to determine the completeness of restoration. I filled the silver sample with a 10% ammonia solution and lowered the cleaned copper wire. No silver deposition on copper was detected. This means that silver has recovered completely.

The silver powder was dried in an aluminum ladle over a fire. The yield was 205 grams.

Now we have to separate the gold from the undissolved sludge.

| Refining of silver |

Safety precautions during refining

When carrying out chemical methods for purifying silver, it is necessary to ensure good ventilation of the room, and it is better to do everything in the open air. As protective equipment, you need to use rubber gloves, special goggles, a robe, and when working with nitric acid, a respirator, because nitrogen vapor, if it enters the lungs, can cause paralysis of the upper respiratory tract. Do not pour water into acid to avoid splashing this caustic liquid. You can only add the concentrate itself to the water.

What clothes should you wear for the refining procedure?

Related video: How to remove silver by electrolysis

Useful articles

The process of chrome plating metal products at home

Carrying out gold refining at home

What is the price of one gram of silver today