Palladium in its pure form is rarely found in nature. It is usually mined from nickel and other ores. To obtain pure material, palladium is refined using hydrochloric acid and oxygen. Industrial technologies for extracting material require the use of hazardous chemicals, so such methods cannot be used at home.

Why is palladium needed?

Palladium refining is carried out at home for the following purposes:

- obtaining pure material used as a catalyst;

- subsequent resale of the precious metal.

They mainly pursue the latter goal, since the metal is constantly becoming more expensive and, if there is a sufficient number of initial components, its sale can bring significant profits. Thus, the cost of a gram of palladium today is estimated at over 1 thousand rubles.

The material is most often obtained from radio components and components that make up modern electronics. In such products, the metal is found in the composition of platinum, silver, gold and other alloys. Less often it was used in its pure form.

It is important to note that the material can only be sold at a specialized point for the purchase of precious metals that has the appropriate license.

Palladium is an expensive metal used as one of the main components of modern electronics. It is mainly mined for subsequent resale.

The method relates to the hydrometallurgy of noble metals and can be used to obtain palladium in metal form.

There is a known method for the reduction of palladium with formic acid, in which formic acid is added to the palladium salt, sodium acetate is added until the alkaline reaction is methyl orange, and the solution is heated in a water bath until the precipitate is completely coagulated (S.I. Ginzburg and other publishers. "Analytical Chemistry platinum metals." "Nauka", M., 1972, p. 203).

The disadvantage of this method is the need to use an additional expensive reagent - sodium acetate, which increases the cost of the process.

There is a known method for producing metal palladium, which involves the reduction of palladium from an acidic or alkaline solution containing chlorine ions and formate ions in stages, in at least two stages, with each subsequent stage starting after completion of the reduction at the previous stage by introducing palladium formate salt into the pulp -ions (Yu.N. Nazarov, N.V. Tulyakov, V.P. Gorbatenko and others. RF Patent No. 2154685 dated 08/20/2000).

The disadvantage of this method is the multi-stage process, which leads to the accumulation of precious metal in the production cycle.

There is a known method of precipitation of palladium from solutions of its chlorides with formic acid at pH 4 for 2 hours. (M.A. Meretukov, A.M. Orlov. “Metallurgy of noble metals. Foreign experience.” M., Metallurgy, 1991, p. 251).

The disadvantage of this method is the incomplete deposition of palladium, as well as spontaneous foaming of the pulp during the reduction process and the formation of a “mirror” due to the reduction of palladium on the walls of the reaction equipment.

There is a known method for producing metal palladium, including dissolving palladium-containing material, precipitating palladium from solution in the form of a salt, separating the palladium salt precipitate by filtration and washing it, dissolving the salt in water, reducing palladium to metal with formic acid at a pH of at least 6 units, separating metal palladium filtration, its washing and drying (L.A. Polyakov, A.N. Tatarinov, Yu.A. Monastyrev and others. RF Patent No. 2210609 dated 08.20.2003).

The disadvantage is the spontaneous foaming of the pulp during the reduction process and the formation of a “mirror” due to the reduction of palladium on the walls of the reaction equipment.

This method is the closest in technical essence to the claimed one and is accepted as a prototype.

The technical result to be achieved by the proposed invention is the elimination of these disadvantages.

The specified technical result is achieved by the fact that in the known method of producing metal palladium, including the precipitation of palladium from a solution in the form of a salt, separation of the palladium salt precipitate by filtration and its washing, dissolution of the salt, reduction of palladium to metal with formic acid at a pH of at least 6 units, separation metal palladium by filtration, its washing and heat treatment - dissolution of the palladium salt is carried out in a solution of sodium hydroxide with a concentration of 80-150 g/l, and the resulting solution is heated for 0.5-1.5 hours.

The essence of the method is as follows.

The process of palladium reduction with formic acid, when carried out in neutral and slightly alkaline media, is accompanied by a violent reaction with the production of fine powders that form thin films (“mirrors”) on the walls of the reaction apparatus.

According to the proposed method, palladium dichlorodiammine salt is dissolved in a sodium hydroxide solution:

It has been experimentally established that the optimal concentration of sodium hydroxide in solution, ensuring complete dissolution of the palladium salt and the smooth occurrence of its subsequent reduction reaction, is 80-150 g/l. When the NaOH content in the solution is less than 80 g/l, the complete dissolution of the palladium dichlorodiammine salt is not achieved and sharp foaming is observed when formic acid is introduced into the pulp. Alkalinization to a concentration of more than 150 g/l does not improve the transfer of palladium into the solution, but leads to unproductive consumption of the reagent.

When the resulting solution is heated, palladium partially precipitates as its hydroxide by reaction (2), which, upon further treatment with formic acid, is reduced to metal by reaction (3) and forms crystallization centers for the growth of powder particles.

It was experimentally determined that the optimal warm-up duration is from 0.5 to 1.5 hours. A shorter heating time does not provide sufficient coarsening of the precipitates and does not prevent the reduction of palladium on the walls of the reaction equipment with the formation of a “mirror”. Longer heating promotes the formation of large hydroxide particles, which prevent the reaction from proceeding completely (3).

Below is an example of the method.

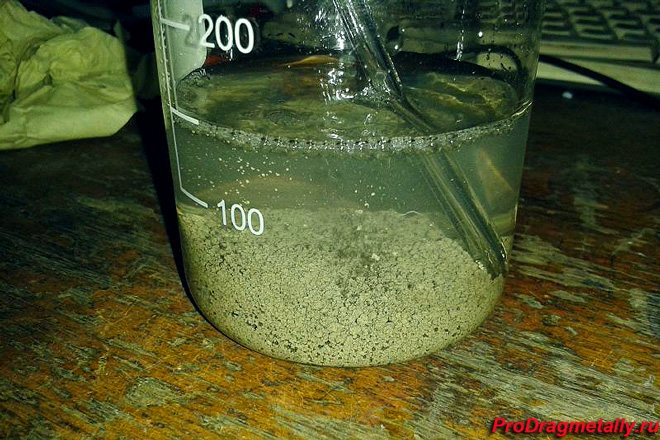

Example 1 (according to the prototype method). Dichlorodiammine palladium salt weighing 100 g with a palladium content of 35.4% was placed in a glass beaker with a volume of 1 liter, pulped in water and treated with a solution of sodium hydroxide to a pH value of 8.5. The pulp was filtered. The solution was treated with a reducing agent - formic acid. After mixing the pulp, the precipitate was separated by filtration and, after washing with water, calcined to obtain metal, which was analyzed for the presence of impurities according to GOST No. 31291-2005. The presence of a “mirror” on the walls of the glass and an increase in pulp volume during restoration were determined visually. The results are in Table 1.

Example 2. Dichlorodiammine palladium salt weighing 100 g with a palladium content of 35.4% was placed in a glass beaker with a volume of 1 liter and pulped in a sodium hydroxide solution of a given concentration. The solution was heated for a given time and then treated with a reducing agent - formic acid. After mixing the pulp, the precipitate was separated by filtration and, after washing with water, calcined to obtain metal. The resulting palladium was analyzed for the presence of impurities according to GOST No. 31291-2005. The presence of a “mirror” on the walls of the glass and an increase in pulp volume during restoration were determined visually. The results are presented in Table 1.

As shown in the table below, the use of the proposed method allows one to avoid spontaneous foaming of the pulp during the reduction process and the formation of a “mirror” due to the reduction of palladium on the walls of the reaction equipment, while the quality of the palladium complies with GOST No. 31291-2005.

A method for producing metal palladium, including the precipitation of palladium from a solution in the form of a salt, separation of the palladium salt precipitate by filtration and its washing, dissolution of the salt, reduction of palladium to metal with formic acid at a pH of at least 6, separation of metal palladium by filtration, its washing and heat treatment, characterized in that the palladium salt is dissolved in a sodium hydroxide solution with a concentration of 80-150 g/l and the resulting solution is heated for 0.5-1.5 hours.

Area of application of palladium

The value of palladium is due to its physical and chemical properties:

- high heat of fusion exceeding 1.5 thousand degrees;

- resistance to water and alkalis;

- good electrical conductivity;

- does not come into contact with ammonia.

In this case, the metal reacts with concentrated nitric acid, and therefore the latter is used for its refining.

The applications of palladium are summarized in the table below.

| Application area | Purpose |

| Catalysts | Palladium catalysts are used to crack oil or detect microscopic accumulations of carbon monoxide in the air. |

| Hydrogen purification | The metal is used to deeply purify hydrogen from various impurities. |

| Electroplating | Palladium chloride is used in electroplating. The latter is used as metallization of dielectrics, for example, in the production of electrical circuit boards. |

| Electrical contacts | Due to their high resistance to wear, palladium alloys are used in the military and aerospace industries to create electrical devices and microcircuits. |

| Jewelry | Adding precious metal to gold allows you to change the color of the latter. |

| Medicine | For the manufacture of medical devices, dentures. |

The material is also used to create:

- measuring instruments in order to prevent the formation of corrosion on their surface;

- chemical equipment such as distillation cubes and others.

Palladium coating helps prevent sparking in electrical contacts.

All products listed in the table can become potential sources of refined metal.

Home methods for determining the authenticity of palladium

At home, you can determine what metal is in front of you, even without deep knowledge of physics and chemistry or expensive equipment in the bushes.

So, if you bought an unmarked ring at a flea market, and the seller insisted that it was white gold, there are several ways to determine whether the jewelry actually contains palladium, or whether it is a nickel alloy. So, how to check what kind of metal is in front of us?

By weight and density

The method is simple and fast. But you will need fairly accurate scales - with an error of up to one hundredth of a gram. And distilled water, it is easy to get at any pharmacy or auto store.

What I did to determine what my ring was made of:

- I weigh the dry decoration – 3.12 g.

- I pour distilled water into a glass, place it on the scale platform and weigh it. The mass of a glass of water is 172.21 g. If the scales have a zeroing function, you can skip this step by simply resetting the scales to zero.

- I hang the ring on a thread and completely immerse it in a glass of water so that the product does not touch the bottom or walls.

- I record the weighted result - 172.48 g.

- The difference between the masses is equal to the volume of the ring. 172.48-172.21=0.27 cm3.

- I calculate the density of the product: 3.120/0.27 = 11.56 g/cm3.

- I look at the table of metal densities on the Internet. There are several suitable ones in the range from 8 to 12:

- silver – 10.49;

- palladium – 12.02;

- nickel – 8.96.

Considering that palladium jewelry alloy usually contains silver and nickel, I conclude that my ring is palladium, and of a fairly high standard. One cannot help but rejoice having determined such a value.

Using nitric acid

Palladium is the only precious metal of the platinum group that dissolves in nitric acid, so by the reaction to a small drop of the reagent we can determine which alloy is in front of us.

If the surface of the metal being tested turns a reddish tint, we can say with confidence that this is palladium. I would like to note that when working with acids you should be extremely careful and use protective equipment.

Using a touchstone

A touchstone is a black slate or jasper plate with a set of needles made of precious metals for testing. From the set, select the needle most suitable in color for the metal being tested and draw a line on the touchstone. Then we clean a small area of our product and draw the same strip on the touchstone.

Then draw a line across the drawn lines with concentrated nitric acid, leave until completely dry and compare the effect of the reagent by color. If the color of the sample matches the sample, it means that it was possible to identify the precious metal.

Using potassium iodide and aqua regia

The method is quite labor-intensive and requires precautions. Aqua regia is a mixture of hydrochloric and nitric acids in a ratio of 1:3. The substance perfectly dissolves all precious metals; it is with its help that their presence in the alloy is determined. Since we are interested in palladium, I will add that it can be precipitated from solution by adding potassium iodide. The process is well shown in the video.

Where to find material

At home, the main source material for refining will be various radio components. By using it in alloys, on the basis of which manufacturers make microcircuits, the developers of the latter manage to significantly increase their service life.

Palladium can be obtained from KM capacitors. In them it is found in the form of an alloy with platinum. The metal is also included in other types of capacitors used in Russian (including Soviet) and foreign radio components. Depending on the type of electrical circuit and its operating conditions, the ratio of the initial components in the alloys may vary.

The precious metal in question is found very rarely in transistors. If it is used in such microcircuits, it is in small quantities. Therefore, transistors are not used in refining to obtain metal.

Palladium looks similar to silver and platinum, as all materials have the same light shade. Visually distinguishing them from each other can be difficult even for an experienced specialist. Materials can be separated using preheated nitric acid: platinum does not react with it. On the other hand, the latter dissolves in a mixture known as “royal vodka”. To carry out this reaction, the starting components must be heated.

Palladium can be isolated from a touchstone in the following way:

- The sharp edge of a metal piece should be pressed across this stone, leaving a scratch on its surface.

- A mixture is made of a 10% solution of potassium and iodine, to which nitric and hydrochloric acids are then added.

- The resulting reagent is applied to the scratch.

If after the manipulations a red-brown spot has formed, it means that the first one contains platinum.

Ceramic capacitors

To carry out refining, it is necessary to prepare expensive components and appropriate utensils. Therefore, in order to avoid additional costs, it is recommended that before starting work, prepare a sufficient amount of starting materials, which contain a lot of palladium.

In modern electronics the content of this material is small. And in order to obtain metal in a relatively large volume, you should stock up on the required number of ceramic capacitors: KM-3, KM-4, KM-5 and KM-6. It is they, according to experts, that meet the above conditions. However, ceramic capacitors are expensive.

You can find CM in electronics produced during the Soviet era. Ceramic capacitors have previously been used in:

- analog technology;

- computers;

- generators;

- measuring devices (E7-14, P2-73);

- oscilloscopes (C-114, 116 and others) and so on.

Ceramic capacitors are the optimal starting material for refining. They can be found in Soviet electrical engineering or contact people involved in gold production. The latter often do not pay attention to palladium.

Examples of refining

Refining is carried out using various methods. To highlight the material at home, the best choice would be:

- electrolysis;

- sequential chemical reactions.

Electrolysis requires highly concentrated sulfuric acid. It replaces the electrolyte. Lead is used as the cathode, and the anode is an electrical component from which the required material is released. During the procedure, the original copper and brass alloys remain intact. After electrolysis, palladium with various impurities is released. To remove them, the metal is placed in hydrochloric nitric acid.

Before starting the procedure, a voltage of 11-13 volts is applied to a container filled with electrolyte. Exposure to electric current leads to the formation of powder or flakes in the vessel. It is in this form that palladium is released.

Electrolysis is a relatively simple method of producing metal. It is more difficult to extract palladium through a chemical reaction, since, depending on the composition of the alloy, the starting reagents are selected. So, to separate silver and gold you will need:

- nitric and hydrochloric acids, including their mixture;

- ammonia.

It is important to remember that in the process of producing palladium through a chemical reaction, many substances hazardous to the body are released into the surrounding space. Before starting the procedure, it is recommended to wear protective equipment (gloves and a mask) and create conditions for ventilation of the room.

Claim

1. A method for producing palladium soluble in nitric acid, including the reduction of a powder suspension of a palladium(II) compound, characterized in that palladium(II) chloride is used as a palladium(II) compound; the reduction is carried out at a temperature of 50-110°C using as a reducing agent, a 20-50% aqueous solution of sodium formate or a 20-70% aqueous solution of ammonium formate, acidified with concentrated formic or glacial acetic acid to a pH value of 3-5 and heated to 50-110°C, and as a For the suspending liquid, acetic acid is used, taken in an amount of 200-400% of the molar amount of palladium in the form of a 70÷100% aqueous solution, or formic acid, taken in an amount of 200-400% of the molar amount of palladium in the form of 60÷95% - aqueous solution, and when using acetic acid as a suspending liquid, the amount of reducing agent is 110-150% of the molar amount of palladium, and when using formic acid - 50-100% of the molar amount of palladium.

2. A method for producing palladium soluble in nitric acid, including the reduction of a powder suspension of a palladium(II) compound, characterized in that palladium(II) chloride is used as a palladium(II) compound and the reduction is carried out at a temperature of 50-110°C with an aqueous solution formic acid, taken in an amount of 200-500% of the molar amount of palladium in the form of a concentrated 60-95% aqueous solution, with the addition of a 5-15% aqueous solution of ammonia until the pH of the solution reaches 3-5.

Separation of palladium from gold

To carry out such a chemical reaction, it is necessary to place the starting material in a mixture consisting of concentrated nitric and hydrochloric acids. This composition is known as “Royal Vodka”. If you have a palladium-silver alloy on your hands, then nitric acid is used as a reagent.

Distilled water is added to the hydrochloric-nitrogen solution. Next, the mixture is kept in this form for about a day, during which the substances are broken down. At the end of the allotted time, a precipitate in the form of silver chloride forms in the container, which should be filtered.

To separate the palladium from the gold remaining in the composition, ammonia is added to the mixture. The container should again be left for two days. Next, the gold solution is filtered. It is recommended to place it in a separate container and restore the precious metal using zinc.

The remaining palladium filtrate is exposed to a small amount of hydrochloric acid. As a result of this reaction, a precipitate appears that has a yellow tint with an admixture of orange. After a few hours, it must be filtered, dried and calcined, heating to a temperature of 500 degrees. The result of this operation will be a powder consisting of palladium.