What is gilding

Gold plating is a thin layer of gold that can hide almost any material. Its thickness can be from 1 to 20-25 microns, and the object becomes practically indistinguishable from gold. The method is used not only in jewelry, but also in architecture, design and even cosmetology.

Brief history of appearance

The art of gilding luxury items first appeared several thousand years ago in Ancient Egypt. It was he who became the first country in which gold mining took on an industrial scale. Since all the mines belonged to the pharaoh, it is not surprising that household items of the ruling family were the first to be gilded.

There is an alternative version that claims that the practice of gold plating originated in China. However, a simple comparison of historical facts speaks in favor of Egypt. The gold-plated sarcophagi of the Egyptian pharaohs date back more than 5,000 years, while in Lao Tang (the province of China considered the birthplace of gilding), thin gold plates have only been produced for about 2 millennia.

The art of gilding, having passed through the Middle East and reached Ancient Rus', received a significant impetus for development and reached a completely new level. It was in Rus' that gold became not just a sign of status and luxury, but also a symbol of faith and divine light.

Expert opinion

Vsevolod Kozlovsky

6 years in jewelry making. Knows everything about samples and can identify a fake in 12 seconds

The popularity of gilding, so beloved by Russian people, led to the creation of an original school, the development of its own methods and secrets. Gilding masters took boys from a very early age to teach them all the subtleties of their profession. And only a few of them actually reached the heights of mastery.

The next step in the development of art is the merit of architects, primarily Bartolomeo Rastrelli. It was he who brought into fashion the Baroque style, which is characterized by gilding not only furniture, but also stucco.

Discovery of the galvanic method by B.S. Jacobi made gilding jewelry safer and easier in the 19th century. Electroplating has taken the technique of applying gold plating to a new level.

History of gilding - Gilding as the oldest type of decorative decoration of objects

Gold is one of the very first metals that man learned to use. Egypt occupies a special place among the states of antiquity, which had its own gold mining and had the largest gold mining industry. In addition to the sun's shine, the second property that was discovered was its incredible plasticity. The ability to flatten into the thinnest film was widely used by craftsmen. Most of the objects found in the excavations of ancient Egypt were decorated with thin plates of gold, which indicates the thriftiness of the ancient rulers, despite the huge reserves of this metal.

The thinnest gold plates at that time were only a few times thicker than those made today. The sheets were attached directly to objects using tiny gold rivets. For fastening to wood, applied plaster was used, onto which the thinnest plates were attached using adhesive substances (presumably egg white). Gold plates were placed on copper and silver using a mixture of gum and glue as an adhesive. The Egyptians made great progress in metallurgy and by the 2nd century. BC. One can clearly judge the use of gold purification. In the 3rd-2nd centuries. BC e. a method of mercury gilding was invented - amalgamation, which was used before the invention of the galvanic method in the 19th century. Ancient Roman writer and encyclopedist Pliny the Elder, who lived at the beginning of the 1st century. AD described a method for obtaining pure gold by purification with mercury

In the medieval era, thin sheets of gold leaf began to be used in painting, as recorded in the Lucca Manuscript of the 8th century. Theophilus described the production and use of gold leaf and created gold in his treatises, where he spoke in detail about the production of gold leaf for decorating the halos of saints and other parts of icons. There, Theophilus also mentioned the use of mercury gold by jewelers, calling it “Flemish” who, just like the Egyptians, obtained a gilded layer by combining mercury with gold, followed by applying it to the object and heating it until the mercury evaporated, resulting in the formation of a persistent layer of gold.

Simon Martini, who lived at the end of the 13th century. was known for his skill in coinage and his various patterned stamps began to spread throughout Italy, but gradually by the 14th century the masters began to replace them with simpler ones and were finally supplanted with the introduction of landscape and architectural backgrounds.

Italy and Western Europe in early Renaissance painting widely used gold leaf to depict clothing. Masters of Northern Europe used created gold in altar painting of various elements of compositions, much more often they used it to depict those places where there is an image of gold in the real world.

Early Christian icon painters used almost all of the listed types of artistic decoration.

From the first icons, Russian master icon painters used all the basic techniques of gilding.

Both the background and the halos of the saints were decorated with a decorative layer; for this purpose, a layer of ocher or, most often, polymenta was coated on the ground (recipes for such gilding have come down to us since the 17th century). By the 17th century, writing with so-called created gold became a new trend in icon painting. Which was prepared by grinding pieces of gold (they also used a mixture of silver and gold called “double&187” with gum and an adhesive composition, after which it was washed and dried; then this composition could be used when writing with a brush. The amalgam method, although it was known to medieval masters, was not used in icon painting did not receive distribution.

With the development of the Rococo style, which replaced the Baroque style in the mid-18th century, it was a time of rise of national culture. The interiors of this period were characterized by a large abundance of gilded elements from household items to the stucco molding of huge halls. An excellent example of this is the hall of the Catherine Palace in Pushkin, Shuvalov Palace, Mariinsky Palace and others. During this period, the method of fire gilding (gold amalgam) became widespread. The method itself has been known since the times of ancient Egypt; in Rus' it was known and used since the 9th-10th centuries and was called the burnt gold method. It was actively used to cover architectural details. This method is very resistant to the external environment, but very harmful in production. To obtain an amalgam, finely ground gold was mixed with mercury to obtain a jelly-like mass, which was applied to the surface with a hard brush, and then heated and after the mercury evaporated, a persistent layer of gold was formed on the surface of the product. Poisonous mercury vapors during evaporation often led to tragic consequences with master gilders who rarely lived to be 30 years old; it is a widely known fact that 60 craftsmen died during the gilding of the domes of St. Isaac's Cathedral in St. Petersburg in the period from 1838 to 1841.

The Old Believers had a special attitude towards copper icons, the resulting patina on which was considered unacceptable. All contamination formed on the icon must be removed to a radiant shine; therefore, in many icons that have survived to this day, the relief images are often erased to a flat or poorly readable state. For greater preservation of such icons, Old Believers often used fire gilding.

This method was replaced in the mid-19th century by the method of galvanic gilding. This coating is more durable, the thickness of the layer can be adjusted, and it has better current and thermal conductivity, which has become widespread in the electronics industry. For galvanic gilding, cyanide electrolytes were initially used; working with them is also subject to risk, and this method of gilding is currently being replaced by acidic non-cyanide electrolytes, which ensure the deposition of shiny coatings with gold-cobalt and gold-nickel alloys. Currently, for additional protection of products, cataphoretic varnish applied by galvanic method is used.

As we can see from the materials collected by scientists and archaeologists, the application of gold plating has been used for a very long time and the main methods of such gilding have been known since ancient times.

Where is it used?

Today, gold plating is used in the following areas:

- jewelry making;

- art (in sculpture; in painting, gilding is used not only on frames, but also directly on paintings);

- Interior design;

- automotive industry (for decorative purposes);

- dentistry;

- electronics (gold is an excellent conductor);

- cosmetology.

The last area of application is the most controversial. Most often, the use of gold in cosmetology is just a cunning marketing ploy. Nevertheless, in Japan they are working on the latest technique of gilding the face. It is believed that this metal enriches the skin with oxygen, preserves collagen and helps relieve irritation.

There is even a separate direction in alternative medicine - chrysotherapy, in which gold is used to treat inflammation. From a scientific point of view, such properties of the metal have not been proven, since a full-scale study of the effect of gold on the human body has never been carried out. But the placebo effect cannot be ignored.

Application methods

There are many known methods of gilding. The choice is determined primarily by the nature of the surface and the professionalism of the craftsman.

Fire or mercury

One of the very first methods that was used for gilding temple domes. Its essence is that a special mixture based on mercury was prepared, which was subsequently evaporated. Due to the danger to the health and life of the master, this technique is a thing of the past.

Oil based

Another name for the method is Mordan gilding, from the name of a special glue. The method is suitable for both interior and exterior work. Mordan can be purchased in specialized online stores.

Clay based

Clay-based gilding (polyment) is used only for wood and is not suitable for exterior decoration. In the old days, this was one of the most difficult and time-consuming methods, since the preparation of polyment required rare and very expensive ingredients at that time, including whale oil. The mixture was diluted using egg white. Now you can find ready-made mixtures on sale.

Water-synthetic

For this method of gilding, mixtures based on water are used. The advantage is that you can quickly prepare the surface. The gold-plated product is glossy and does not require final polishing.

Garlic

One of the oldest methods. Fresh garlic juice was squeezed onto the surface. After it dried, the surface was polished, moistened and gold leaf was applied. According to experts, this method gives the gilding a special shine.

Electroplating method of applying gold plating.

Deposition of thin layers of gold from fractions of microns to tens of microns under the influence of electric current.

The main advantages of this type of gilding are wear resistance, high reflectivity, and the ability to apply controlled thicknesses of the gold layer. Electroplating is widely used both in the field of decoration and in the application of technical coatings . It has high conductivity and protects against the effects of aggressive environments, corrosion, oxidation and other undesirable destructive phenomena.

The main disadvantage of electroplating is that this type of gold plating can only be applied to conductive surfaces, i.e. metals. Although today there are technologies that allow electroplating with gold, including on dielectrics (non-conducting materials). This was made possible through the use of conductive varnishes and processes for activating conductive films.

Thus, galvanic gilding compares favorably with other methods of applying gold to products.

Kinds

The most common type is still gilding. Also in recent years, gold leaf gilding has become popular among decorators, which is much more accessible and cheaper.

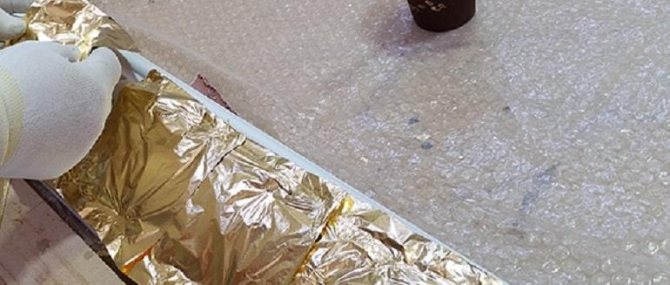

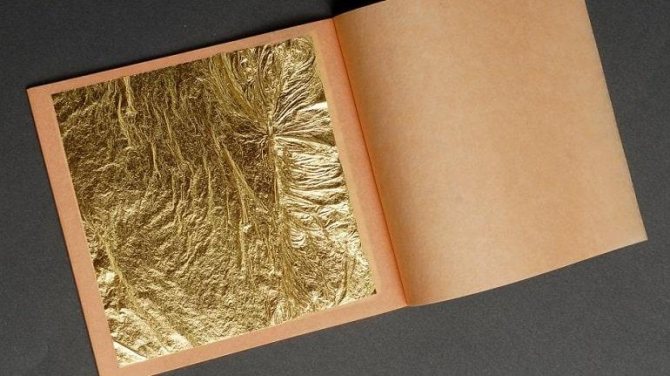

Gold leaf

Gold leaf is 960-carat metal, rolled out to a thin sheet. In Rus', gold leaf was traditionally used to cover the domes of churches. In Russia it is sold in the form of books of 60 sheets with an area of 10 cm2 each.

The thickness is not regulated, but the most popular sheets are 10 times thinner than a human hair. It is used to decorate objects of art and for interior design. For outdoor decoration (fountains, domes, sculptures) thicker sheets are used.

Potal

Potal is a replacement for the usual gold leaf. It appears as gold sheets or strips and is an alloy of copper and zinc or aluminum. There is a potal imitating gold, silver and bronze. A drawing can be applied to the sheets. You can find gold leaf on sale in the form of multi-colored crumbs.

What are their differences?

The main difference between gold and gold is that it does not contain precious metal. This naturally affects its price: gold leaf is much cheaper. Without a protective coating, it may fade over time.

Difference between gold and gilding

The main difference is in the composition. Even a professional cannot always distinguish them by their appearance. Gold jewelry is durable, since the layer does not wear off, and is often much more expensive. Due to their short service life, gold-plated items are not worn every day and require more careful care.

With the development of technology, new methods of gilding have appeared. They allow you to achieve a thicker coating. Such bracelets and rings last much longer, but their price is higher than regular gold plated ones.

What is gold plating and how does the transformation occur?

Gilding is a special type of finishing when a thin layer of noble metal is applied to the surface of an item. This coating looks good on any material - from plastic and wood to glass and ceramics. And due to the fact that almost any object can be processed in this way, the range of applications of this technology is very wide - it is used in the creation of jewelry, in the production of automobile parts, and for the production of paintings, books and even church domes!

There are different ways to apply gold plating. Now, due to its speed, ease and safety, the galvanic method is the most widely used. To do this, you need to prepare a special electrolyte solution containing gold molecules. Next, the cleaned products are hung on stands and lowered into a container with the composition, through which a current is passed. Under the influence of charged particles, a thin layer of noble metal settles on the surface of the works. All that remains is to remove them, inspect them and, if necessary, repeat the process until the coating becomes dense enough.

Not only the appearance, but also the durability of the jewelry depends on the care with which gilding is carried out. So, cheap jewelry wears out within a couple of days after purchase. Accessories that combine silver with gold plating are much more durable - jewelry made using this technology can be worn for years. By the way, prices for such a procedure are quite affordable - on average, treatment costs from 15 UAH. for 1 gram.

How to spot a fake

According to statistics, 4 out of 10 gold jewelry is fake. Unfortunately, you can buy gilding for the price of full gold even in a jewelry store. There is only one method of checking that would allow you to avoid counterfeiting at the purchase stage - make a transaction in large, trusted jewelry stores and be very attentive to the product itself.

Signs that jewelry is fake:

- Uneven color. Gold plating can wear off in places even with careful storage and transportation. Moreover, the fakes use a very thin layer.

- Some “experts” on the Internet advise checking with a magnet. Gold should not be magnetic. However, given that many metals do not react to magnets, this method is practically useless.

- Very often, scammers remove the stamped lock from real gold jewelry and attach it to gold plated jewelry. Therefore, one way to identify a fake is to carefully examine the links next to the lock. Any defects in this area may indicate that this is a fake.

At home, if the product has already been purchased, it is much easier to check:

- Chemical method. You can purchase a special set of reagents for testing. This method is suitable for those who often buy gold and not always in reliable places.

- You can drop alcohol onto the surface: low-quality gold will darken.

- If in search of the truth you don’t mind spoiling the appearance of the jewelry, then you can scratch the surface. Small particles will fall off the gilding, leaving noticeable damage.

The most reliable way to check is always a consultation with a specialist. For a small fee, any pawn shop will conduct a series of tests and samples to ensure authenticity.

How to distinguish gold from gilding

Knowing the difference between gold and gold plated items is important when choosing jewelry in stores. How is gold plating marked and what does it mean? As a rule, factory-made jewelry is stamped and hallmarked. But the presence of a hallmark on a Turkish necklace does not guarantee that it is made of gold.

In most countries, the abbreviations 14, 18 and 24 KHG (KHG-carats) are used to denote the composition. If the marking KHGE, KARATCLAD, Cold Layered is present, the product is not made of gold, but has a gold-plated surface.

How to check gold or gilding?

Uncertified products can be submitted for examination. A free test option is a candle flame. The decoration is brought to the fire and held for 15-20 seconds. If stains or dark spots appear on the surface, the item is gilded.

Care, cleaning and storage of gold-plated items

In order for your jewelry to last as long as possible, you must follow a few simple rules for caring for gold plating.

| Wearing | Be sure to remove gold-plated jewelry before any contact with water (shower, swimming pool, washing dishes) or sports activities. Avoid contact with cosmetics. Don't forget that everyday wear shortens their service life. |

| Storage | Store only in a separate box or fabric bags so as not to damage the layer with other decorations. |

| Cleaning | Clean only with a soft cloth without using abrasives. If dark spots just appear, just wipe with ordinary vinegar and rinse in water. The shine will help return the egg white (after it you will also need to rinse in clean water). Once a year, items should be taken to a jeweler for professional cleaning. |

Despite the fact that sooner or later the coating wears off, it can always be renewed in a jeweler’s workshop.

Gold plating methods at home

With certain skills, compliance with safety precautions and the presence of a well-ventilated room, gilding can be done independently at home.

Preparation and use of gold chloride

Procedure:

- Prepare aqua regia.

- Dissolve any gold item in it.

- Carefully evaporate to a dry residue.

Attention: the process must be carried out very carefully, since acid fumes can cause serious harm to the respiratory tract, and there is also a high risk of chemical burns to the skin.

- Mix the resulting gold chloride with chalk and a solution of potassium cyanide to a mushy state.

- Using a brush, cover the product.

- After the surface has dried, it must be thoroughly washed and polished.

Application of zinc contact

If a thicker layer is needed, then zinc is used. It is also necessary to prepare gold chloride for it.

Procedure:

- Clean the item thoroughly and degrease it.

- Prepare the composition by mixing gold chloride with carbonic potassium, yellow blood and table salt in water.

- Heat.

- Place the item to be gilded in a container with a warm mixture.

- When the products are already in the solution, place a zinc stick in the container.

- Rinse, dry and polish.

If necessary, the product is covered with a protective layer.

Galvanic method

The galvanizing method is similar to galvanizing, but produces a more durable coating. By changing the composition of the solution, you will get different shades of gold. You will need a current rectifier and any glass container that can withstand high temperatures.

Procedure:

- Clean, degrease the product, sand it using paste and sandpaper.

- If the product is made of steel, zinc or tin, first coat it with copper.

- Prepare electrolytes from water, sodium phosphorus, gold chloride, potassium cyanide and sodium disulfide.

- Heat the resulting solution to 60 °C.

- Install the anode.

Electroplating takes from 12 to 16 hours. At the end of the process, the product is dried on sawdust and polished.

If gilding of a small surface is required, it is easier to purchase a special galvanic pencil.

Gilding on the Gulfarba

Gilding “on Gulfarba” allows you to get a matte finish. Gulfarba is a mixture of varnish, drying oil, and pinene. The surface is treated with Gulfarba, and the next day a layer of gold leaf is applied to it. Thanks to the solvent in the composition, the surface becomes matte.