How to get gold at home? Secret mining methods

Even the word “gold” itself has a magical effect on a person, not to mention its appearance. Let dreams of gold-bearing rivers and mines remain dreams. However, for those who still want to feel like a gold miner, we can offer a very real way - gold mining at home. Of course, we are not talking about kilograms, but you can get enough metal to use it for practical purposes.

Benefits of home gold mining

There are many thematic articles and forums that talk about effective methods of making money from home gold mining. And although initially such an idea may seem pointless, given the poor economic situation in the country, even such an activity can become a good source of additional income.

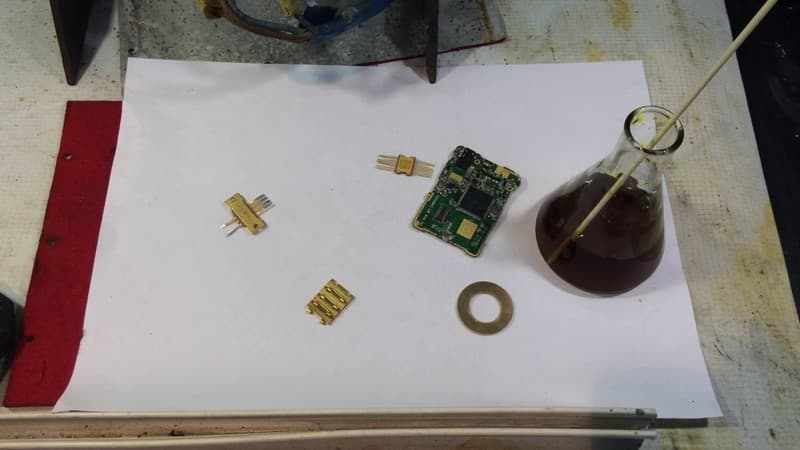

For the upcoming startup you only need a few components, namely :

- Corresponding parts and microcircuits.

- Chemical compositions.

- Diligence and desire to work hard.

The effort expended can be justified by the high cost of gold, which almost never sags in price and is a stable currency. Naturally, it is not advisable to place too high rates on gold mining at home. First, you need to make sure that such a field of activity can be promising in a particular region, weigh the many pros and cons, and also consult with professionals.

You also need to understand that the purchase of precious metals is carried out only by officially registered companies that have the appropriate licenses. Regular scrap buyers will not be willing to pay an adequate price for homemade gold.

In addition, refining and refining of precious metals is permitted only in large specialized companies that are regulated by government agencies. Without obtaining official permits, such activities will be illegal. And if the laws are not followed, a curious enthusiast can receive a serious fine, as well as be subject to sanctions and lose all collected equipment.

In any case, we must not forget that in home workshops and old mezzanines there are many expensive things that can be of real value. Some of them are right under your nose, but few people know about their value. And in order to learn how to extract precious metal from supposedly unnecessary garbage, you should carefully consider the existing methods of such gold mining, familiarize yourself with the general principle and all the pitfalls, and also correctly perform all the steps from the instructions.

Properties of gold

Gold is a precious metal that is widely used in jewelry. However, in addition to its jewelry value, it should be noted that its unique electrical conductivity determines its use in electronics, where in critical parts it is necessary to ensure low resistance with minimal dimensions. It is these parts that become the main raw materials for home gold mining.

When organizing gold mining and processing, its basic properties should be taken into account:

- High specific gravity. This characteristic is used when implementing technologies such as washing, when heavy weight causes gold grains to settle.

- High ductility, facilitating forging of metal when making jewelry from it. Very thin threads can be made from gold.

- Inertia. Gold does not react chemically with most known acids, alkalis and solvents. Only aqua regia and some solvents can affect it. This property is very important for organizing the extraction process.

- Lower melting point compared to other metals and minerals, which makes it possible to smelt gold from products and make jewelry from the melt.

Attention. Being in a molten state, gold quickly evaporates, which must be taken into account when melting it.

Subtleties of refining

Modern technologies are so developed that with their help you can carry out a wide variety of actions and achieve excellent results. As an example, we can take refining production, which allows you to effectively process various precious metals, purifying them from unnecessary impurities and additives.

The following objects may be subject to refining::

- Jewelry in the form of scrap.

- Concentrated metals.

- Scrap gold.

- Metal waste.

The process itself is a series of specific actions that are intended to produce high-quality gold. The complex consists of several stages of purification, which make it possible to completely rid the precious metal of third-party components, giving it the highest quality and appearance. The procedure is carried out using two methods :

- Chemical.

- Electrolytic.

The first option involves the use of special compounds and is actively used in jewelry companies. Many enthusiasts have successfully purified gold from waste using chemical methods and in their home workshop. The main thing is to follow the basic rules and not allow exposed parts of the body to come into contact with a dangerous substance.

To implement chemical refining, you should use a special solution of ferrous sulfate or ferrous sulfate, which are diluted in water in a certain proportion. Jewelers can also use a liquid called aqua regia, which effectively removes impurities from gold. You can even use regular hydrogen peroxide for cleaning.

Where is gold found?

The home craftsman needs to be prepared for a labor-intensive and painstaking process, because... the available raw materials have a meager gold content and are difficult to extract. Precious metal can be extracted from the following materials:

- Parts of radio equipment and electronic devices - microcircuits, transistors, diodes, capacitors, resistors, switches, motherboards, connectors, processors. A sufficient amount of gold for extraction is contained in relays such as RES, RPS, RPV, RKG; lamps from old radios and televisions. The GMI series radio tubes stand out in particular. Gold-containing parts can be found in televisions, radios, computers, tape recorders, VCRs, mobile phones, refrigerators and other household appliances. The presence of such parts, as a rule, was indicated in the equipment passport. Modern technologies make it possible to do without the use of precious metals, and therefore they should be looked for in the parts of old instruments and devices. It should be noted that Soviet-made products were distinguished by a large number of valuable parts.

- Costume jewelry . Gold can be extracted from spoiled, damaged, deteriorated earrings, rings, pendants, pendants, brooches and other jewelry that has gilding or inclusions of valuable elements.

- Watch . Of interest are products with coating on the case or hands, and bracelets.

- Cutlery and souvenirs . These can be forks, spoons, dishes, figurines, decorative elements with gold plating.

Mining process at home step by step

Gold mining at home can be organized in several ways. They are based on the following principles:

- Dissolving the base . To obtain the precious metal, it is enough to expose products with surface gold (watches, dishes) to a powerful solvent. This technique is based on the unique inertness of gold, which is not affected even by concentrated acid. To implement the method, it is enough to place the coated product in a glass container and fill it with concentrated nitric acid. All metal parts will dissolve in 3-4 days, and the gold will precipitate.

- Etching . This principle is based on the complete dissolution of details. In order to dissolve gold, you will need a “hellish mixture” in the form of a combination of hydrochloric and nitric acid - “aqua regia”. In such a liquid, gold only dissolves, and all other ingredients do not simply dissolve, but chemically react with the acid, forming the corresponding compounds. Under these conditions, the introduction of the necessary reagents allows gold to be precipitated from solution. You can use hydroquinone, hydrazine, hydrogen peroxide, sodium sulfite, and ferrous sulfate. Etching technology is most suitable for extracting gold from small parts of electronic devices.

- Electrolysis. High purity gold can be obtained by electrolysis. The gold-containing radio component serves as the anode, and 2 lead or iron plates are installed as the cathode, connected at the top by a conductor. The electrolyte is hydrochloric acid. When a direct electric current is passed (with a density of 0.6-0.7 A/sq.dm of anode area), gold gradually transfers to the cathode plates and settles on their surface.

Gold etching techniques

When implementing these methods for obtaining gold from various parts, it is necessary to follow a certain procedure. The first production option involves the following work:

- Accumulation of sufficient quantities of raw materials. Removing all elements that have no value. Only gold-plated elements with a minimum content of other materials are prepared for processing.

- Place the raw material in a glass container and fill it with concentrated nitric acid.

- After 3-4 days (provided the base is completely dissolved), the solution is filtered through gauze layers.

- The resulting sediment is placed in a glass container and filled with ethyl alcohol or vodka. Exposure is 22-25 hours.

- The brown precipitate is washed and filtered, after which it is sent for melting. To obtain a purer metal, it is recommended to add soda to the melt.

Most often, gold is extracted from radio components by etching. This technology is implemented in the following sequence:

- Accumulation of sufficient quantities of raw materials for processing.

- Preparation of “royal vodka”. Hydrochloric (3 parts) and nitric (1 part) acid are mixed in a glass container with utmost care.

- The raw materials are cleaned of dirt and loaded into “royal vodka”.

- The liquid is heated to accelerate dissolution. The process is considered complete when the parts are completely dissolved and the solution turns bright green.

- Gold precipitation. For these purposes, you can use a solution of hydroquinone, prepared by adding 50 g to 1 liter of water. This composition is carefully poured into a vessel with aqua regia, maintaining a concentration of 10 ml of hydroquinone per 1 liter of solvent. Next, the container is left for 3.5-4 hours.

- The solution is carefully filtered, and then the gold deposited at the bottom of the container is evaporated and dried. The sediment looks like thin pieces of yellow foil.

How to Store Etched Finished Metal

Home gold mining is characterized by tiny portions of the precious metal, and therefore it is necessary to minimize its losses. Thus, at the final stage of gold evaporation, it is recommended to add borax and soda to the resulting sediment, which will reduce waste and simplify further processing. It is better to immediately pour the resulting metal into specially prepared molds (crucibles).

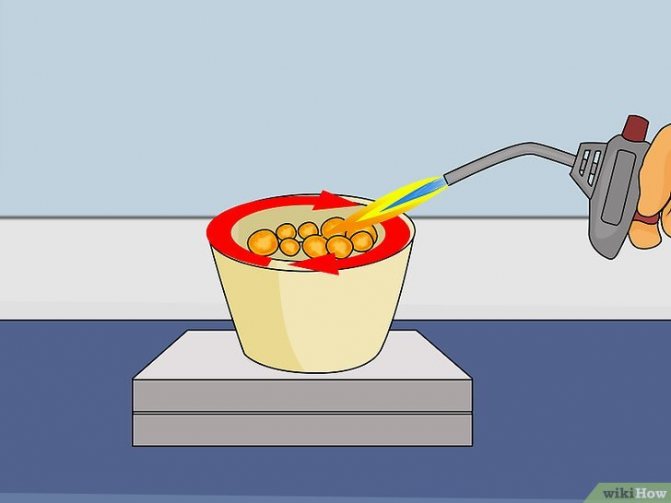

Small burners or muffle furnaces are used to melt gold. The molds are made of cast iron or alloy steel and have a collapsible design. Most often, gold is stored in the form of small bars. Depending on the quantity of the final product obtained, it is sometimes shaped into rods or wires.

Features of working with reagents

When mining gold at home, you will have to deal with very aggressive and harmful chemicals. It must be remembered that acid vapors (especially when heated) are extremely dangerous for the human body.

During the work, nitrogen oxide is released, which can damage the respiratory system, even leading to death. Frequent and prolonged inhalation of harmful substances can cause chronic diseases. Concentrated acids can cause severe chemical burns to both the skin and mucous membranes.

Important. When carrying out work at home, precautions must be strictly observed. Good ventilation of the room must be ensured at all stages. You can only work with rubber gloves, safety glasses, a respirator and a protective apron.

Withdrawal without heating

There are other gold mining methods that do not require such dangerous manipulations with hot toxic liquid. However, they require much more time and effort and take approximately 7 days. During this period of time, the precious metal will be completely cleansed of unnecessary impurities. All that remains is to pass it through a special filter, usually paper, and treat it with methyl alcohol. The sediment should be further dried and melted into an ingot.

There are other methods of extracting precious metals, but they are very complex and also unsafe. To obtain gold, the following methods and available means are used :

- Electrolysis.

- Sulfuric acid.

- Hydrochloric acid.

But even the most effective methods do not guarantee complete purification of the metal from trace elements and alloys, so ideal purity cannot be achieved. Nevertheless, based on the sample, the resulting precious metal will be of very high quality. To finally solve the problem with the presence of impurities in the composition of the feedstock, it is necessary to refining gold from radio components. This procedure involves deeper and finer cleaning of the material to achieve almost perfect cleanliness.

Use of the received gold

Home-mined gold can be used in a variety of ways. At the same time, we should not forget that obtaining a permanent income in this way requires obtaining an appropriate license. In general, the following options stand out:

- Sale of gold bars or handing them over for sale. To achieve the desired appearance, they are polished using toothpaste applied to the rough surface of the metal with felt.

- Preparation of jewelry solder for repairing gold jewelry. This solder is made by mixing the resulting gold with various additives. For example, to repair products with 585 purity, the following solder recipe is used: gold - 585 parts by weight (parts by weight), copper - 185 parts by weight, silver - 116 parts by weight, cadmium - 112 parts by weight. For ease of use, solder is prepared in the form of a paste - tinol.

Jewelry making

At home, you can make various simple jewelry - earrings, pendants, rings, rings, chains. The most common method is casting into special molds. The resulting precious metal is melted in small containers with a spout. Heating to the required temperature is provided by a muffle furnace. Next, the melt is directed in a thin stream through the hole into the mold. If necessary, the metal is carefully forged. Making complex products requires a set of special jeweler's tools.

Mining gold at home, with your own hands, is a labor-intensive but completely doable process. The precious metal can be found in old radio equipment and various electronic devices. To extract it, chemical reagents are required, when working with which you must be careful. Gold lies idle nearby and can be mined without searching for a gold-bearing vein.

Illegal mining: what threatens “black” miners

The legislation provides for two types of liability if gold is mined illegally. The Administrative Code provides for a fine of 3 to 5 thousand rubles. Equipment will not be confiscated. But this is only if the volume of precious metal mined has a cost of less than 1,000,000 rubles. Otherwise, the Criminal Code comes into force, since the amount is especially large. But criminal structures and competitors pose a greater danger to illegal immigrants working illegally.

Practice has shown that they, without a twinge of conscience, hand over “their brother” to law enforcement agencies. They do not receive any profit. But they take away the equipment, space, etc. There are many cases where people were killed in remote parts of the country. There is a place for racketeering in this area. The fact is that a “black miner” cannot contact the police, since he himself works illegally.

Is it possible to pan for gold in the nearest river with your own hands? Let's mine gold together. Video

When such values are everywhere, there are always people who find these values. Since childhood, I heard about poachers collecting emeralds in mine dumps. To be honest, I had to hold them in my hands

. Our land is rich.

And there is a lot of gold too. Not in bank safes, but scattered on the ground. Even in the sand from which we make concrete for our construction sites, there is a little gold

.

We live on gold. It is everywhere, in every stream. The only question is in what quantity

.

They started mining it a long time ago. Everyone knows the Berezovskoye deposit, where Russian gold mining began. So it’s very close! Suburb of modern Yekaterinburg

.

The peculiarity of Ural gold is that it is small. There is a lot of it, but it is scattered in the form of dust and is simply not visible. A long time ago, humanity learned to collect this dust on an industrial scale, shoveling many hundreds of cubic meters of rock.

Such a scale is needed to mine gold in kilograms, but what if you don’t need kilograms, but a few tens or hundreds of grams? What should I do?

I have an old friend. Since childhood I have been fascinated by geology. So passionate that it became his professional occupation. But he does not mine gold himself, he develops

equipment for individual gold mining

. Can you imagine? The same as that of industrialists, but only much smaller in size. Fits in the trunk. When I found out what he was doing, I was a little stunned and immediately asked to visit.

The first thing I saw when entering the office was some pieces of iron and rubber bands. Dmitry said that he had just returned from testing new equipment. They panned for gold

somewhere nearby. He said that the test went wonderfully, all the calculations were justified, the equipment would go into production.

In itself, the process of gold mining is not too complicated. Rather labor intensive. You select a stream rich in gold, install the equipment and shovel soil into the bunker. Large stones are sifted out immediately, and clay and gold, in the form of dirty water, flow down the sluice. Flowing along a long path, water carries with it particles of clay and small grains of sand. And gold. The water carries away the clay, and the heavy gold lingers on the fibers of the carpet, which is called “moss.”

, gradually accumulating.

Precise settings come with experience. The same goes for the carpet parameters. The size and depth of the cells, the relief - all this was selected during the testing process. This is not just a corrugated elastic band; a lot of effort and knowledge was invested in its development. And hundreds of cubic meters of soil are being tested.

For several hours, the prospector scoops up soil with a shovel and throws it into the receiving bunker. Shovel by shovel, cubic meter by cubic meter. Water carries away everything unnecessary, and gold concentrate accumulates on the carpet. Having considered that enough is enough, everything that remains on the carpet is collected in a tray and washed by hand. This is called "finishing"

. Then we count the gold coins found. If there are quite a lot of them, we continue to wash them; if there are catastrophically few, we move to another place.

In fact, the art of the prospector is not in installing and configuring the equipment correctly, but in finding a place where

install it. Based on signs and experience. For example, gold accumulates in fast streams at their sharp turns. But rivers have a habit of changing their course. Sometimes gold is found away from the current riverbed. Where the river flowed a hundred thousand years ago.

It is not necessary to scoop the soil with a shovel. You can install a pump and use a special ejector to suck sand from the bottom of the stream.

Having collected enough concentrate, you can begin the final separation of gold from waste rock, finishing

. This is done by hand using a prospector's tray. This is not just a frying pan, as some people think. This is a pretty smart product. Every part of it is carefully thought out. Shape, dimensions, depth and shape of the recesses, their ratio. All this serves one purpose - to allow the waste rock to float away, leaving only heavy and valuable gold.

According to Dmitry, he purchased trays from all world-famous manufacturers and tested them personally. Based on the experience gained, our own design was born, taking into account the disadvantages and advantages of all those tested. His trays are sold by the thousands all over the world.

Dmitry even got acquainted with gold mining in Southeast Asia with their wooden trays. Do you go to Thailand to sunbathe? And he wandered along the rivers and panned for gold along with local miners. Maniac. ツ

Romance or earnings

Prospectors are divided into two categories. Some people need vivid impressions, privacy, excitement, and earnings come in the background. Others live by it. Naturally, both of them dream of finding the biggest nugget. And such cases do happen. It is important to know how to search correctly. You immediately need to determine what the earner wants:

- Sand deposits . Sieves are used, washing is carried out more thoroughly, and the water pressure is set more powerfully. The upper layers of bottom sediments are washed.

- Nuggets . Only large sieves are used, the washing is less active, so as not to wash the nugget into the river. Soil lying at a depth of more than 0.3 meters is subject to washing.

The difficulty is that manually selecting bottom soil to a depth of 30 cm to 1 meter is physically difficult. One tray is not enough. You need a tool that allows you to scoop up rock. Pumping equipment and mechanization are used, which also costs money.

What can you get Au from?

Telephones, radio tubes, diodes, computers, microcircuits, connectors—devices containing radio components—are excellent starting materials. The main requirement for them is that these products have a long production period, that is, they must be old. In Soviet times, a large volume of precious metal was used to create radio components; accordingly, the older the device, the more gold can be extracted from it.

Modern devices containing radio components include SIM cards and laptops, although they contain much less precious metal compared to devices from the times of the USSR.

I also use gold-plated items as a source material - cutlery, jewelry, watches. But you shouldn’t expect a large amount of Au in such things: the sputtering on the bodies of such products is applied in a very thin layer, and in order to get a decent amount of gold, you will need to collect more than a dozen pieces of jewelry.

Danger of chemical processes

If you want to start melting old radio components and microcircuits in order to process them into precious metal, you need to understand that any interaction with acids can be accompanied by unpleasant consequences. Depending on the method used, the procedure itself can last for a long period of time. If we talk about “regia vodka,” that is, the refining of metals, then this requires at least six hours of hard work.

During this process, too much nitrogen is released, so this action should be carried out in a closed area with good ventilation. During the procedure, the windows must be opened for free circulation of air flows.

Just one breath of poisoned air can seriously harm your health and lead to painful death. Unfortunately, the process of poisoning of internal organs occurs too quickly, so doctors simply do not have time to provide the victim with the necessary assistance.

After the first cleaning with aqua regia, small flakes with a brown tint should appear on the surface. Unfortunately, the quality of such raw materials is not entirely high, but if repeated cleaning with acids is applied, it will increase significantly.

It should be noted that in Soviet times, gold was almost always combined with copper. But isolating such metal and carrying out the removal process is not entirely simple. This may take several hours. The effort expended is justified by the fact that the final product is obtained in almost pure form - 999 purity.

Metal mining methods

There are several ways to obtain AU. Regardless of the chosen method, the raw materials must be prepared before starting work. I sort old and new items into two groups. Then, within each group, I classify devices according to the amount of expensive element it contains. Unnecessary parts in products or old devices are removed to save time and chemicals.

Etching method

The basis of this method is the inability of the precious metal to participate in a chemical reaction with any substances other than aqua regia. Aqua regia is a mixture of hydrochloric acid and nitric acid in a ratio of 1:3.

The method involves making the mixture yourself. The substance has a pungent odor, is initially colorless, but after a short amount of time it becomes light yellow.

I recommend preparing the composition immediately before using it; This way the oxidation function remains at its maximum level.

During the chemical reaction, gold does not oxidize, but remains on the surface of the liquid. He needs to be put down. To do this, you will need to add a reagent to the aqua regia. Hydrogen peroxide, oxalic acid, and sulfite are often used as it, but I recommend using iron sulfate. After adding it, the gold remains on the surface, resembling pieces of foil. I then filter the solution by passing it through a dense material.

Electrolysis mining technology

To mine gold in this way, I will need to fill a glass container with hydrochloric or sulfuric acid, then install 2 iron or lead plates into it. I connect them together with copper wire, then I place a microcircuit there and run an electric current. The microcircuit in this case is the positive electrode.

Under the influence of electric current, a reaction occurs and gold begins to settle on the plates. As soon as the process comes to an end, I turn off the current.

Which way is better

Each method has advantages and disadvantages. Compared to the etching method, the electrolysis method has a more complex technology, but it requires fewer reagents for extraction.

The etching method requires strict adherence to safety precautions, since the likelihood of getting a chemical burn is very high.

These methods are the most effective ways to mine gold at home.

Features of working with reagents

When mining gold on my own, I have to deal with very dangerous substances that have an aggressive effect on human health. For example, nitric oxide released when heated can threaten human life.

How to grow weed at home for your pet

For germination, it is better to buy seeds at a pet store; there is a special set of cereal herbs for cats. Choose a low pot that is narrow at the base and wide at the top. Fill it with soil, plant the seeds, sprinkle a 1-2 cm layer of soil on top and water. The soil must be compacted well so that when the cat pulls the grass, it does not pull the entire bouquet out of the pot. The first time after germination, it is better to cover the pot with a plastic bag. This will preserve moisture better, the grass will grow faster, and the cat will not damage the tender sprouts. When the grass grows a little, the bag needs to be removed.

If your cat has a constant need for fresh grass, then you need to make several of these mini-greenhouses. Sow the grass at weekly intervals. Just while your cat is finishing one portion of greens, you will have time to grow the next crop for her.

Grass can be grown in the traditional way - in a bowl with soil, or using “home hydroponics”.

Growing in the ground. Take a short, stable plastic or ceramic container. Fill it with soil, carefully distribute the seeds on top and sprinkle with soil, water. Cover the bowl to create greenhouse conditions for grain germination, and place it in a dark, warm place. Open the bowl daily and spray water on the grains. When you see shoots appearing, remove the lid and place the “grass” in a bright place, water daily. After a week, when the “grass” has grown, place the bowl in a place accessible to your cat and just watch it.

Pros and cons of this business

If we put aside the legality of this process, then I highlight certain advantages:

- production does not require large expenses;

- the process is clear and uncomplicated;

- good payback;

- does not require a lot of time.

However, I also found some disadvantages:

- the reaction is unsafe;

- a large number of things are required to extract, which are not so easy to find;

- Obtaining a license to legalize a business is a rather labor-intensive and time-consuming procedure.

Jewelry making

When making jewelry, I use the casting method. To do this, gold is heated in a special container with a burner and poured into a casting mold in a thin stream.

After hardening, I look at the resulting shape of the decoration and, if necessary, process it with forging.

Mining gold at home is exciting and interesting. I won’t talk about making a big profit from this business, but I will be able to earn a certain amount. The main thing is to follow safety precautions and not play with the law.

Subscribe to updates and share useful links on social networks!