Among all the precious metals, gold is considered one of the most popular. Thanks to such unique characteristics as resistance to corrosion and the negative effects of aggressive environments, this metal is loved by many jewelry makers. Due to the fact that gold is relatively soft, processing it with special equipment will not be difficult. Beginners often ask the question, how to melt gold at home? According to experts, home craftsmen can do this. To make any jewelry from this noble metal, it is not necessary to contact a specialist. You will find information on how to melt gold at home and what you need for this in this article.

Getting to know metal

Surely many of the buyers wondered why gold is so expensive? The reason for this is the attractive color, thanks to which gold products look very impressive.

In addition, this material has a lot of advantages that make it popular in industries such as jewelry, medicine and industry. In its natural form, gold can be represented by grains or nuggets. Therefore, before being sent to a store or bank, the gold is processed. This is mainly a factory procedure. However, judging by numerous reviews, it is also successfully implemented in a homemade way. Read on to learn how to melt gold at home.

About the melting point of gold in degrees

According to experts, gold of the highest standard will melt at a temperature of 1064 degrees. This applies to 999 gold. If a different thermal regime is applied, this will lead to complete burnout of the precious metal. Newbies often wonder whether it is possible to melt gold on a gas stove? Due to the fact that the temperature resulting from the combustion of natural gas depends on the distance to the burner, experts advise not to take risks.

Near the burner itself, the temperature ranges from 300 to 400 degrees. Having reached its peak, it will be 1500 degrees. Before you begin, you should know the exact melting point of gold in degrees. Precious metal of 375 standard will melt in a mode not exceeding 770 degrees. 585 standard - at a temperature of 840 degrees. It is considered the most popular among professional jewelers. This sample is often faked by scammers. According to experts, it is impossible to melt 999 gold using a homemade method. It is possible to achieve a temperature of 1064 degrees only in factory conditions. Some home craftsmen, out of ignorance, make the mistake of using ordinary welding machines as a means of heating. However, these devices can only melt steel. If the welding machine is used for gold, the precious metal will completely evaporate.

Melting methods

Folk craftsmen have invented many devices for artisanal melting of precious metals. Modern Kulibins can make an electric furnace at home, melt gold in a microwave, barbecue, gas welding, deposit gold by electrolysis, make a gasoline, propane or oxy-acetylene burner for melting, or even decide to use a gas stove for melting.

I strongly do not recommend the last option, unless you want to start a fire in your own home. In addition, gold melted on a gas stove heats up for a long time, unevenly and mixes with atmospheric air. Such an alloy will be very brittle.

Among several popular methods of melting at home, I have chosen for you three that, in my opinion, are the most reliable.

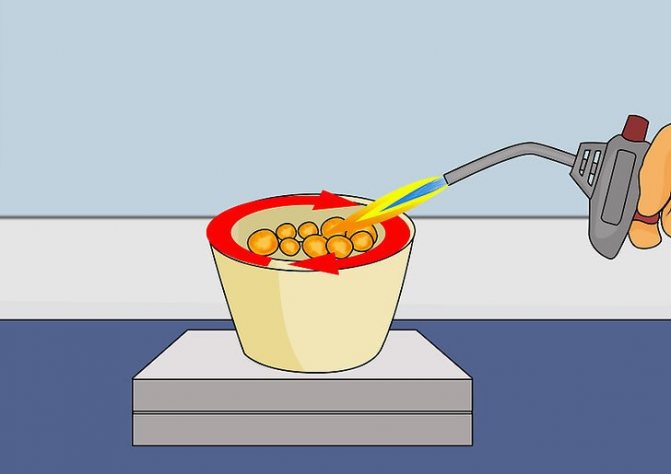

Burner

The most affordable and fastest way to melt small volumes of solar metal. You will need a gas canister with tourist gas (a mixture of butane and propane) or acetylene, and the burner itself, which is easy to buy at any hardware store or order online. The main thing is that the unit has a sufficiently high efficiency. The device data sheet indicates the maximum temperature - compare it with the melting point of gold.

This video shows that a 15g gold bar can be melted in about 5 minutes even at home.

You can melt gold using a gasoline torch. It is not inferior to gas, but is more often used for jewelry soldering of finished jewelry.

Using a homemade oven

For those who plan to engage in melting regularly, I recommend purchasing a jewelry muffle furnace. Or you can be patient and make such a stove with your own hands at home.

Melting furnaces are either electric or charcoal-fired. How to make such a stove is a separate topic, I will only say that a variety of materials are used for its manufacture: refractory bricks, cement slabs, steel cylinders of different diameters, stainless steel beer kegs and other materials resistant to high temperatures.

It should be remembered that for such furnaces it is better to use charcoal: its heat transfer when air is supplied is 1280 ⁰C. This is enough to melt gold, but coal can heat the metal above the melting point of steel.

Microwave

Yes, you can bake an original gold bracelet for yourself in your home microwave oven! But seriously, 1200 watts of power is enough to melt precious metals. The method is suitable for those who systematically engage in jewelry making: if you use your microwave to melt metals at least once, you will no longer be able to cook food in it.

A few important points:

- The magnetron in a microwave oven should be located at the back or side - this is the main condition.

- Clay crucibles are not suitable for microwave oven conditions. The optimal crucible is graphite.

- It will take about 8 minutes to melt a few grams of silver. It will take 12-15 minutes to melt 3 grams of gold.

To start melting precious metals at home, you will need to remove the rotating disk from the microwave oven and make a heat-resistant chamber from two refractory bricks.

Which way is better

Everyone can choose for themselves which method suits them best. It all depends on the melting objectives, profitability, availability of raw materials and budget. For one-time operations at home, a gas burner is ideal. Inexpensive and effective, does not require time to manufacture, melts quickly and well.

The furnaces are well suited for those who do smelting regularly. The advantages are minimal losses and the ability to control the melting temperature. But it will require certain investments.

What will you need for work?

Before you melt gold at home, you need to have the following:

- Crucible. If for pure gold the melting point is 1064 degrees, then for alloys containing copper, more heating will be required. Therefore, there is a need for a container that can withstand high temperatures. If you couldn’t get a crucible, you can use a potato. It is enough to cut a hole in the center of a raw root vegetable for gold.

- With tongs. Preference should be given to products made from heat-resistant materials.

- A flux used to purify gold. It is presented as a mixture containing borax and sodium carbonate. According to experts, at least two pinches of flux are required to clean one ounce of precious metal. You can also cope with this task using bicarbonate and baking soda.

- A furnace for melting metal. Electric furnaces for working with precious metals are presented to consumers in specialized stores. Judging by numerous reviews, home craftsmen use microwaves for this purpose. However, not every microwave oven will do. It is imperative that its power is not lower than 1200 W, and the magnetron is located in the side or rear part. According to experts, it is not recommended to further heat food in a stove that contained molten gold. If there is only one microwave in the house, and the master is not ready to sacrifice it, then we can recommend that he purchase a gasoline burner.

What is the heating device made of?

If it is not possible to get professional equipment, you can melt gold using a gasoline burner. Before you start making it, you need to acquire the following:

- Airbrush spray. An air injector or garden equipment that sprays chemicals is quite suitable for this purpose.

- A jar. It is important that it has an airtight lid.

- Automotive air pump. A machine compressor is also suitable.

- With a hose.

- Sealant.

Melting using a homemade furnace

If it is not possible to buy a muffle furnace for melting gold, you can make a furnace for melting metals. The first thing you need to do is identify the requirements for such a stove. It should be compact and easy to use and at the same time have a wide heating range. With enough skills, you can assemble such a stove at home yourself.

It will look like this: carbon graphite powder is poured between two electrodes, which are made of graphite and to which a voltage of 25-50 V is transmitted. For the stove you will need a very powerful transformer (suitable for a welding machine). Graphite powder produces gradual and intense heat due to its characteristics, making gold melting as efficient as possible. The main advantage of such a furnace is the fact that it can heat the required sample to very high temperatures, including those necessary to melt gold.

The furnace heats up in 3-5 minutes, which allows you to quite accurately control the metal soldering process. The oven itself is made from available materials: ceramic or cement tiles, mica and graphite. The dimensions of the furnace, that is, the distance between the electrodes, directly depends on the output voltage of the transformer. The volume of the furnace will be enough to melt several grams of metal.

Brushes from a powerful motor are used as electrodes; holes should be made in the sides for stranded copper wire. It is necessary to make a notch on the inside of the electrode to improve contact with the powder. Reinforce the outer walls with tiles, and use bricks as a stand. Used rods are suitable for carbon graphite powder.

Melting gold occurs like this: in the middle of the furnace, a hole is made in the powder, where the metal is placed and buried. To make sure that it has melted, you need to shake the furnace - if the surface of the powder fluctuates, the molten metal is turned over and heated further. Melt until the molten liquid becomes homogeneous and acquires a spherical shape.

How to make a burner?

The melting device is made as follows:

- First, the jar needs to be equipped with two holes into which the hoses will be inserted.

- Insert the hose connected to the pump into the first hole, and the sprinkler hose into the second hole.

- The connected hoses are carefully sealed.

At the end of the work, make sure that the gasoline and air exit through the injector nozzle. The flame must be blue. Judging by numerous reviews, such a device is no worse than a special furnace for melting metal.

Melting process

When the gold scrap has been thoroughly sorted and crushed, you can begin to melt it. To do this, flux is poured into the crucible. Then gold should be placed there. If the pieces have different diameters, then the larger ones are placed in the crucible first. It will be more convenient to add smaller scrap during melting. Then the furnace with the crucible located in it is turned on. You should wait until the scrap melts completely. Only after this can it be poured into molds. After the precious metal is poured, they begin to harden it with alcohol or water. If the melting procedure is carried out not in a special furnace, but using a homemade burner, then the process looks different. The crucible should also be treated with flux. The best option for this purpose would be borax. Next, a gold scrap is placed inside. Alcohol is poured there and set on fire. You should wait until the alcohol burns out completely. Then the crucible is placed on the bricks and the gasoline burner is ignited. The flame should be blue in the central part and yellow at the edges. They begin to melt the precious metal. At the end of the procedure, the molten scrap is poured into molds and hardened.

Melting scrap gold

If you want to melt gold scrap at home, then a simple barbecue is no longer enough. The heat from the coal on the fire is not enough to melt the gold and alloy. A ligature is a mixture of non-ferrous metals added to pure gold to improve the physical properties of the alloy. Typically the alloy contains the following metals:

- silver;

- copper;

- rhodium;

- nickel;

- palladium;

- chromium.

Silver and copper are contained in different proportions in yellow and red-yellow gold alloys. If there is more copper in the alloy than silver, then the alloy gets a red tint. If there is more silver, then the product turns out yellow. If the product does not contain copper, but contains about 50% silver, then it acquires a slight greenish tint. Rhodium, nickel, palladium and chromium are found in white gold.

If the gold scrap contains more than 24% copper, that is, the scrap has a very red and slightly dull tint, it cannot be used for figure casting. Such an alloy can only be heated and drawn out. You can also make jewelry from it using printing.

Algorithm of actions:

- Before melting scrap gold, the raw materials must be sorted by shade.

- Next, the gold scrap needs to be crushed. The smaller the particles, the faster they will melt.

- After this, the raw material must be poured into a crucible and placed in a muffle or electric arc furnace.

- Immediately after melting, the liquid gold must be removed from the furnace and poured into the mold. During prolonged melting, the alloy burns out first, and then the gold.

- Immediately after casting, gold should be hardened. The faster it cools, the stronger the product will be; water and alcohol can be used for hardening.